Hydraulic retarder lubricating system

A technology of hydraulic retarder and lubricating system, which is used in hydraulic resistance brakes, lubricating parts, engine lubrication, etc., can solve problems such as retarder not working, unable to obtain effective oil lubrication, bearing damage, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

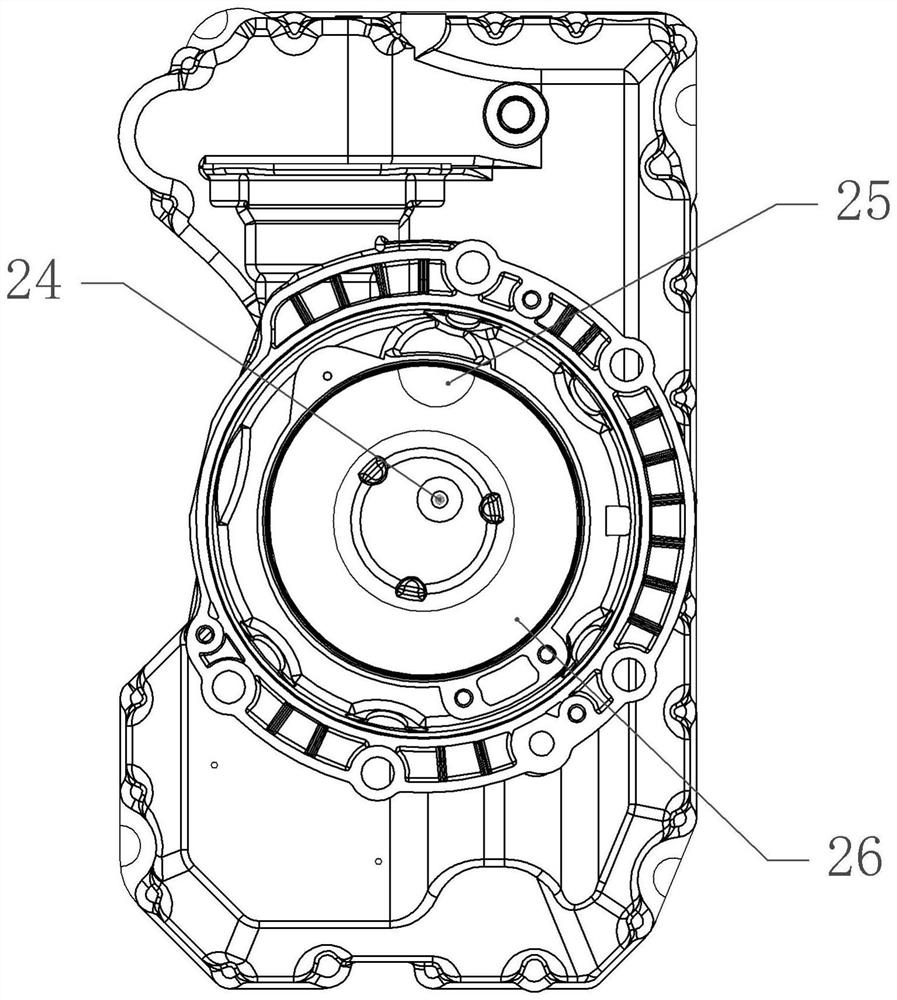

[0035] Basic as attached figure 1 And attached figure 2 As shown, a lubricating system for a hydraulic retarder includes a middle casing 11 of the hydraulic retarder and a rear casing 18 of the hydraulic retarder, and a seal is arranged between the middle casing 11 and the rear casing 18 components.

[0036] In this embodiment, a working cavity 26 is integrally formed on the rear casing 18, and the working cavity 26 is circular and grooved. The rear casing 18 is provided with a first oil hole 24 located in the middle of the working cavity 26 and a The second oil hole 25 on the peripheral side of 26, in this embodiment, the positions of the first oil hole 24 and the second oil hole 25 can be changed according to requirements, and the rear housing 18 is integrally formed with a raised cylinder 12, and the raised cylinder 12 There is a penetrating oil inlet hole inside, and the oil inlet hole communicates with the first oil hole 24 .

[0037] In this embodiment, the sealing a...

Embodiment 2

[0045] The difference between the second embodiment and the first embodiment is that it is basically as attached image 3 And attached Figure 4 As shown, the middle housing 11 is provided with an oil return hole 31 communicating with the working chamber 26, and the middle housing 11 is integrally formed with a hollow oil return column 32 with openings at both ends, and the oil return column 32 communicates with the oil return hole 31 .

[0046] In this embodiment, the oil pressure plate 14 is provided with an oil return hole 33 , the metal gasket 16 is provided with a metal gasket oil return hole 34 , and one side of the oil storage chamber is integrally formed with an oil return chamber 35 . The oil return column 32 extends into the oil return chamber 35 through the oil return hole 33 of the oil pressure plate and the oil return hole 34 of the metal gasket, and the oil return column 32 communicates with the oil return chamber 35 . The oil return chamber 35 communicates wit...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com