High-speed cantilever type hub motor of mobile platform

A technology for mobile platforms and hub motors, which is applied to electrical components, electromechanical devices, and electric components. It can solve problems such as accelerating the wear of the mandrel and mandrel bearings, amplifying the force deviation of the mandrel, and serious component loss, etc., to improve work efficiency. Reliability and stability, increased structural strength, and improved service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

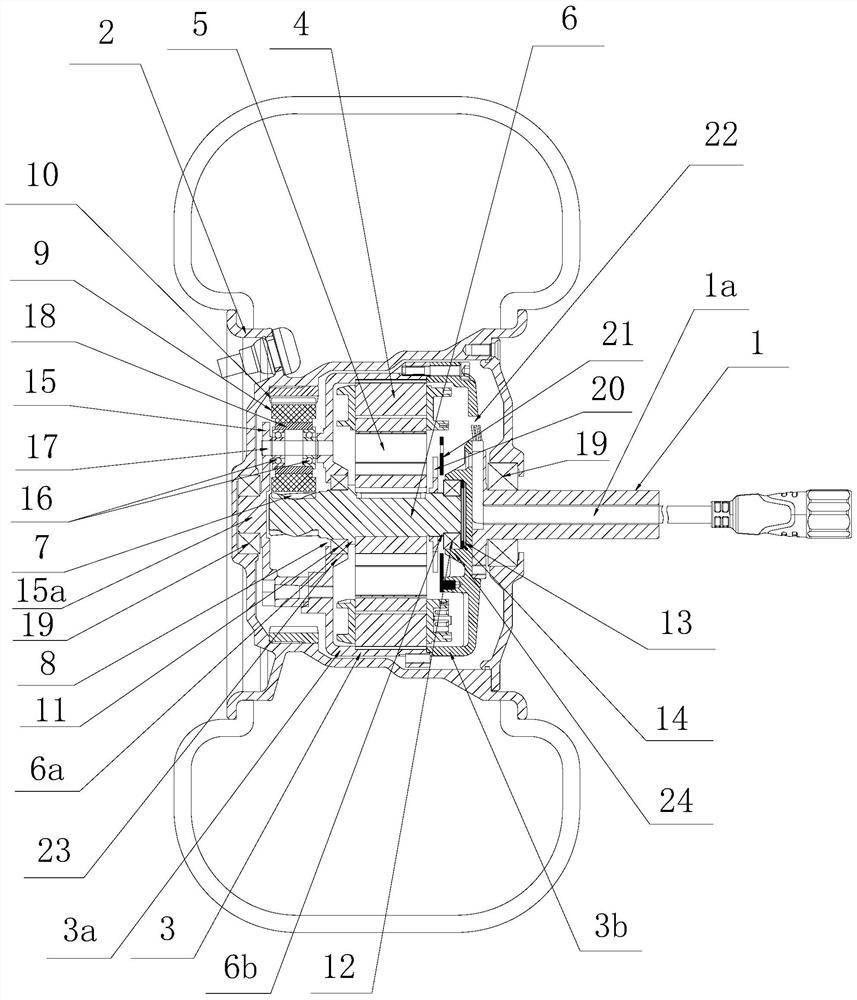

[0024] Example: such as figure 1 Shown is a specific implementation of the high-speed cantilever hub motor for the mobile platform of the present invention, which is mainly applied to golf carts.

[0025] Same as the conventional technology, this wheel hub motor has the hub housing 2 with the cantilever shaft 1 as the center of rotation and the core housing 3, core and planetary reduction mechanism located inside the hub housing 2, and the core housing 3 is fixed on the cantilever shaft. 1 front end, the movement has an outer stator 4 and an inner rotor 5 structure, the stator 4 is fixed on the inner wall of the movement casing 3, and the center of the rotor 5 is fixed with a mandrel 6 coaxially arranged with the cantilever shaft 1, and the front end of the mandrel 6 is provided with The shaft teeth 7 extend out of the shaft hole 8 at the front of the core casing 3 and mesh with the planetary gear 9 in the planetary reduction mechanism through helical teeth, and the planetary ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com