Positioning and punching device for metal plate machining

A technology for positioning punches and metal plates, applied in positioning devices, metal processing equipment, storage devices, etc., can solve problems such as poor punching effect of metal plates, poor positioning stability of punches, and inability to quickly replace punches, etc., to achieve replacement Fast and convenient, improved accuracy, high stability effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

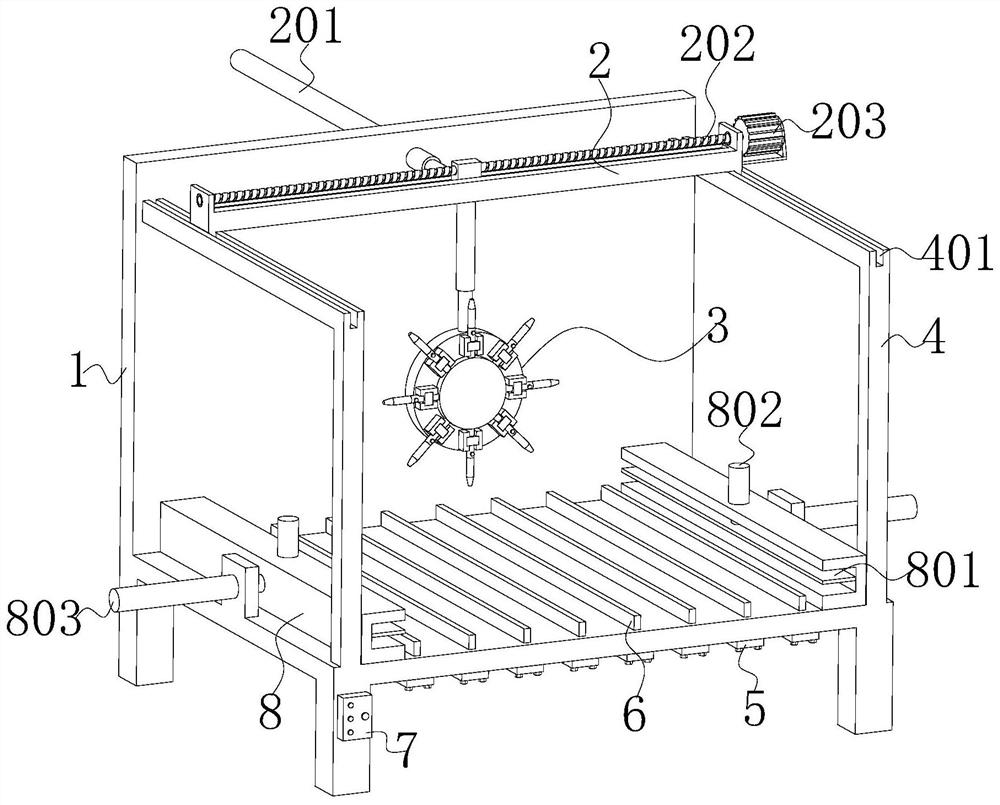

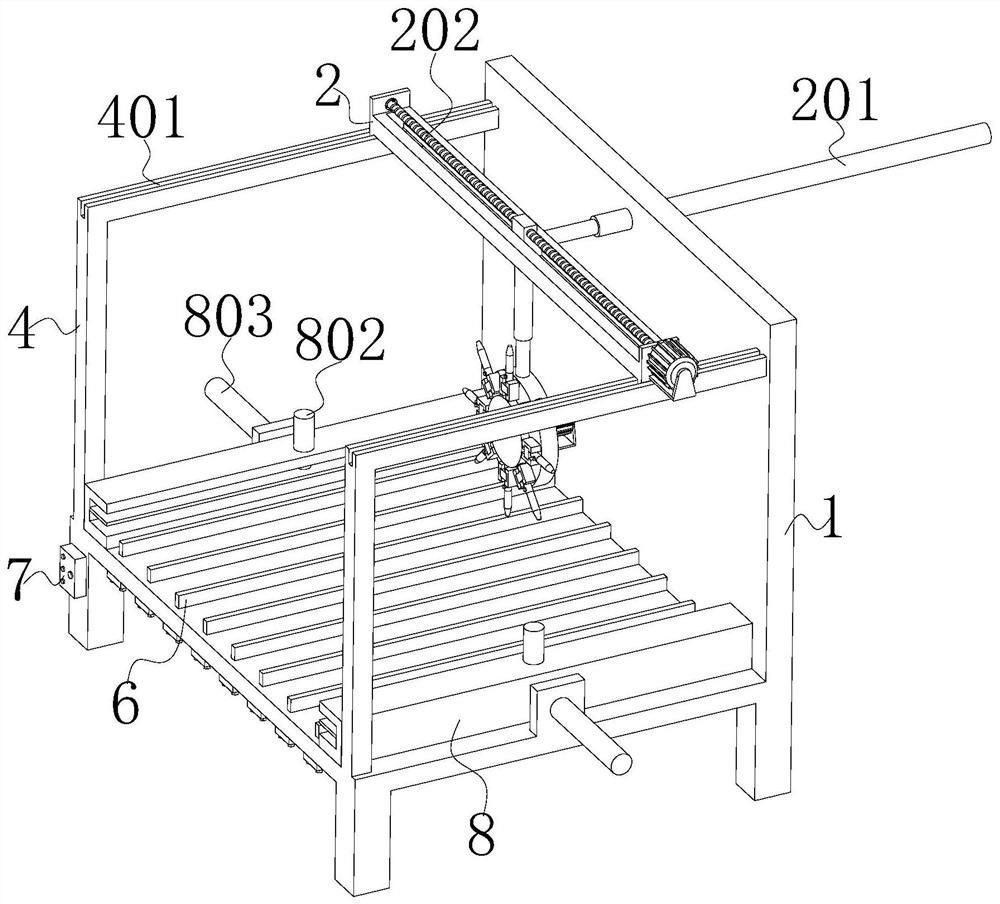

[0050] see Figure 1-2 As shown, the present invention is a positioning punching device for metal plate processing, including an operating table 1, a moving frame 2 and a punching mechanism 3. As can be seen from the accompanying drawings, the above-mentioned components constitute the basic structure of the device, and the operating table 1 is arranged in an L shape as a whole, and two L-shaped support frames 4 are arranged symmetrically on both sides of the front end of the console 1. The top surface of the support frame 4 is provided with a second sliding groove 401, the top surface of the L-shaped support frame 4 is slidingly fitted with a mobile frame 2, and the mobile frame 2 is equipped with a punching mechanism 3 for movement.

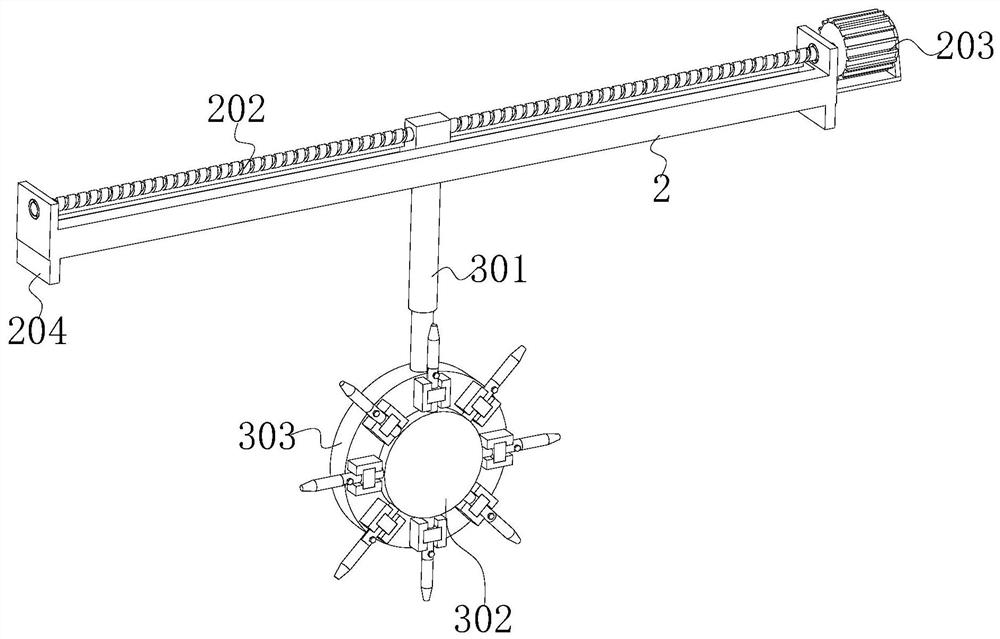

[0051] see Figure 5-9 As shown, the punching mechanism 3 includes a rotating disk 302, a fixed disk 303 and a first hydraulic cylinder 301, one end of the first hydraulic cylinder 301 is fixedly connected to the side top of the fixed disk 303,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com