Adjustable dynamic vibration absorber and adjusting method of dynamic vibration absorber

A vibration absorber and basic technology, applied in the field of automotive NVH testing, can solve problems such as unsatisfactory effect, poor effect, long cycle, etc., and achieve the effect of flexible adjustment methods and wide frequency adjustment range.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0024] This embodiment proposes an adjustable dynamic vibration absorber and a tuning method for the dynamic vibration absorber, which can be used for debugging the vibration absorber during the development process, thereby speeding up the development progress and saving development costs.

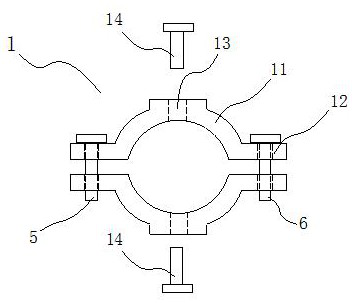

[0025] like Figure 1~5 As shown, the adjustable dynamic vibration absorber of this embodiment is composed of a base 1 , a bracket 2 , a basic vibration absorber 3 and a mass 4 detachably mounted on the basic vibration absorber 3 . Both the base 1 and the support 2 are made of aluminum alloy.

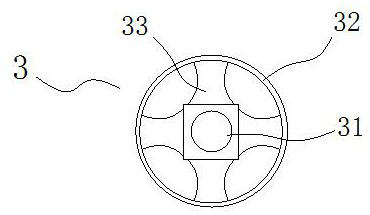

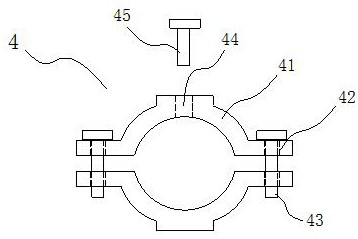

[0026] Specifically, the basic vibration absorber 3 includes a central steel installation pipe 31 and an outer steel sleeve 32, and the installation pipe 31 and the sleeve 32 are connected by several rubber blocks 33 distributed radially; The mass block 4 is composed of two or more steel split blocks 41, the split blocks 41 are composed of arc bars and protrusions located at both ends of the arc ba...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com