Driving assembly of crow bar bending bicycle

A technology for driving components and bicycles, which is applied to vehicle components, rider driving, transportation and packaging, etc. It can solve the problems of pedals not being able to rotate circularly and not being labor-saving enough to achieve reasonable structural layout, avoid conflicts between parts, and solve bending angles oversized effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

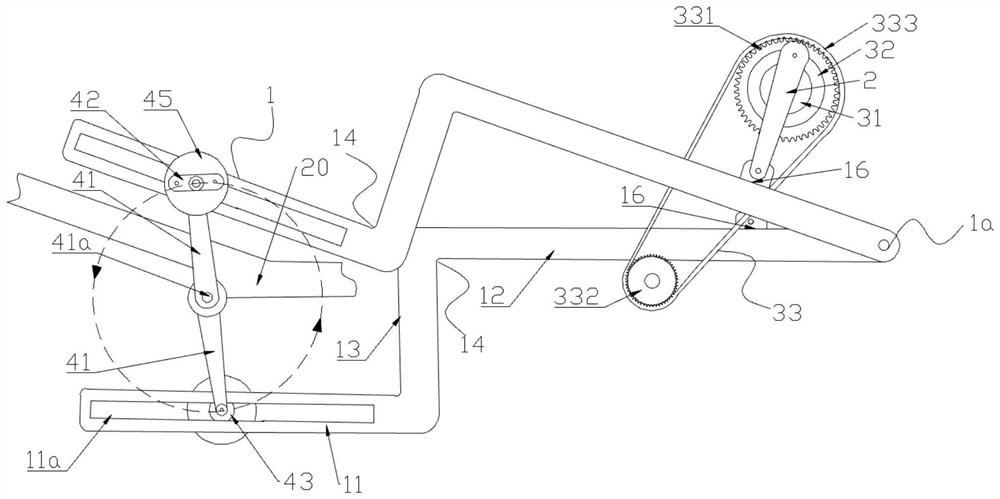

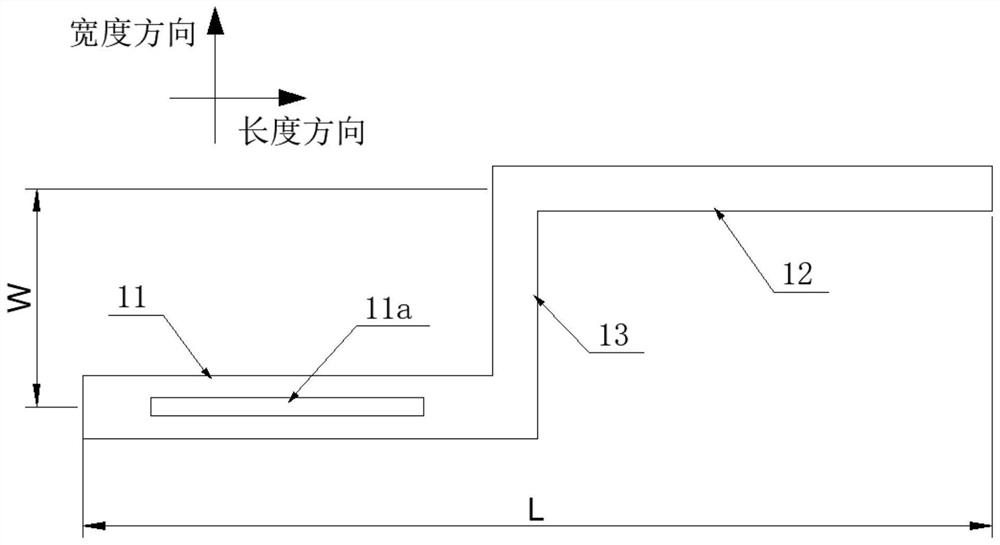

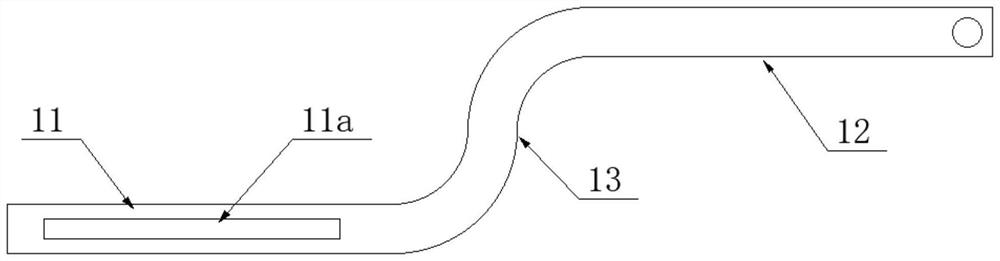

[0042] Such as Figure 1-3b , 8-9, shown in 12, the present invention provides the driving assembly of crow bar crank bicycle, comprises crow bar 1, crank bar 2, flywheel crank mechanism 3 and pedal assembly 4, and flywheel crank mechanism 3 and bicycle Rear wheel 5 transmissions are connected, pedal assembly 4 comprises rotating rod 41, pedal 42, and the first end of rotating rod 41 is rotatably hinged on the vehicle frame 20, and pedal 42 is installed on the second end of rotating rod 41, and crowbar 1 includes a first crowbar 11 and a second crowbar 12 that are not on the same straight line, and the inner ends of the first crowbar 11 and the second crowbar 12 are connected by a first connecting section 13 to form a complete crowbar 1, the first crowbar 1 The crowbar 11 , the second crowbar 12 and the first connecting section 13 can be integrally formed, or can be manufactured separately and assembled to form a whole, preferably the former.

[0043] Such as figure 1 , 2a ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com