Construction method for building artificial rock plug body and water intake in reservoir

A construction method and water intake technology, which are applied in water conservancy projects, general water supply conservation, construction, etc., can solve the problems of rock plug blasting safety risks and hidden dangers, and achieve the effects of reduced engineering difficulty, high safety, and shortened construction period.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

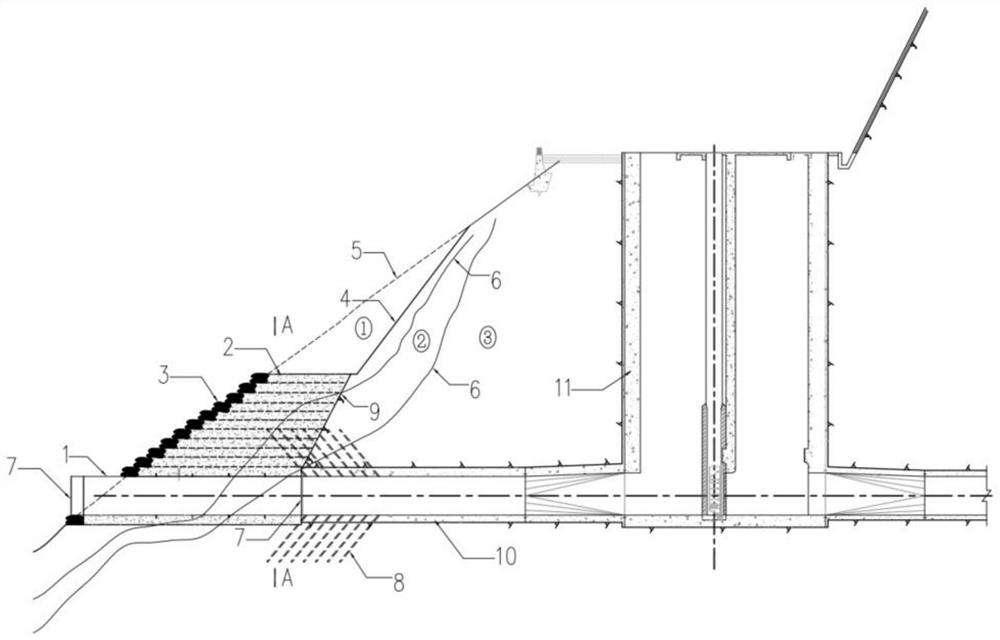

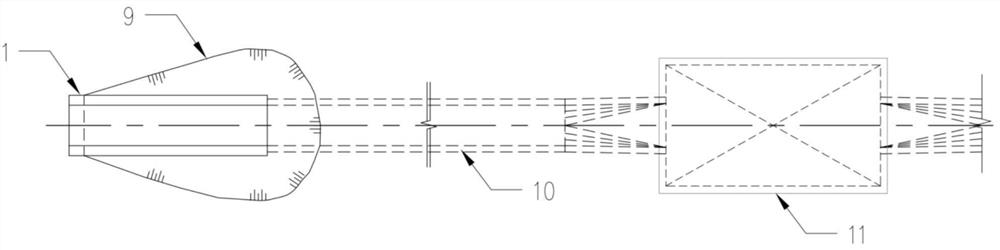

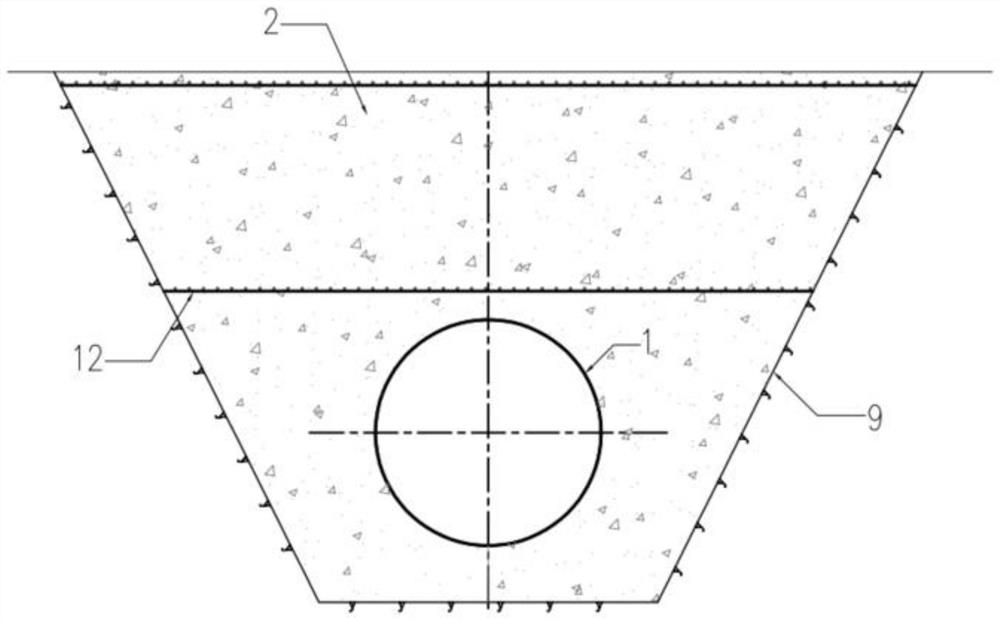

[0029] Such as Figure 1 ~ Figure 3 Shown, the construction method of building permanent artificial rock plug body and water intake described in the present embodiment in built reservoir, comprises the following steps:

[0030] (1) During the low water level window period of the reservoir, the strong weathered overburden layer on the surface of the underwater slope at the proposed water intake should be removed by means of underwater excavation and underwater blasting by grab boats to form underwater trenches;

[0031] (2) Flange covers are reserved at both ends of the prefabricated water intake pipe, and the prefabricated water intake pipe is sunk to the designated position in the trench in the form of an immersed tube, and the water intake pipe protrudes from the underwater slope by no less than 1.0m;

[0032] (3) Stack sand bags layer by layer on the edge of the underwater trench, with a height of 0.4m to 1.0m for each layer, and set the steel mesh above the water intake. ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com