Design method for profile of offset elliptical pin hole of piston

A design method and ellipse technology, applied in the direction of piston, design optimization/simulation, mechanical equipment, etc., can solve the problems of increased shear stress, easy cracks in the piston pin hole, etc., to optimize contact and reduce safety risks.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] The present invention will be further described below according to the accompanying drawings.

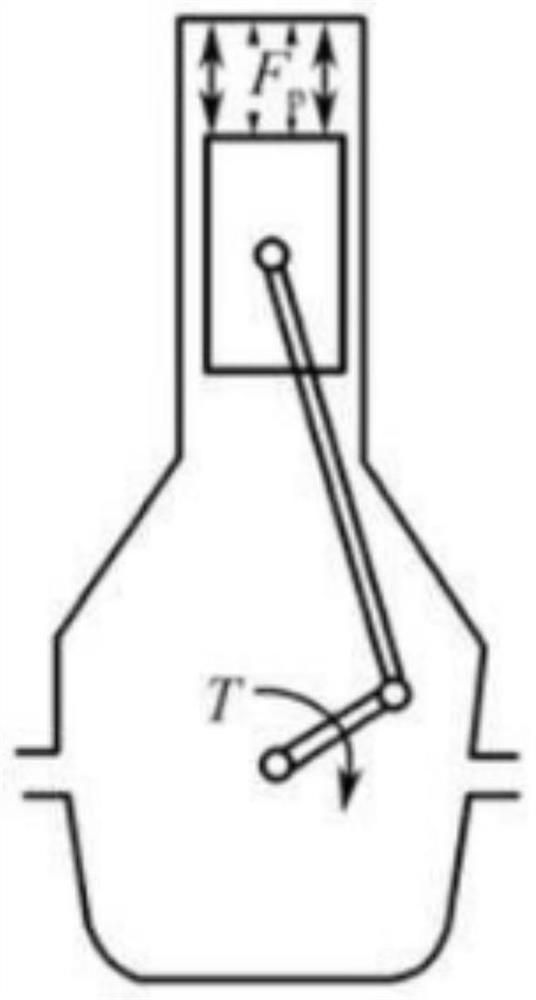

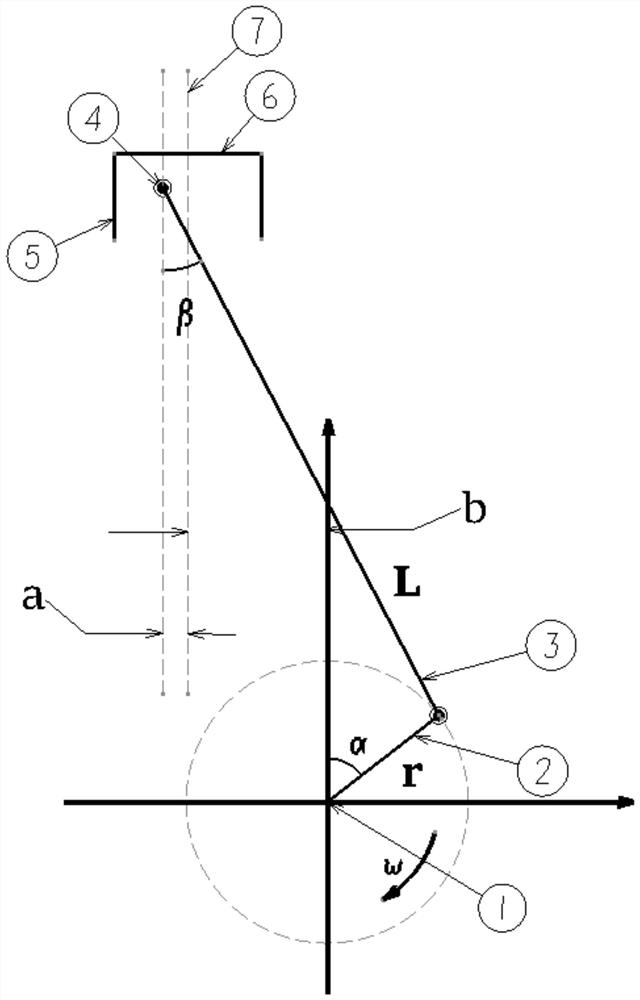

[0023] Such as image 3 As shown, the power transmission route of the traditional engine is that the combustion chamber converts the chemical energy of the combustion chamber composed of the piston and the cylinder head into mechanical energy, and then converts the reciprocating motion of the piston into the circular motion of the crank 2 through the crank mechanism. In the process of power transmission, due to the swing of the connecting rod 3, the contact area between the piston pin hole and the piston pin will also change continuously. However, the gas pressure and inertial force received by the piston body 6 are always along the cylinder bore centerline 7 direction. However, due to the supporting effect of the connecting rod 3 of the piston, the contact pressure of the piston pin hole is mainly biased towards the TS5 area on the main thrust side of the piston skirt. As t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com