Data-driven engineering material ultra-high cycle fatigue life prediction method

A technology for fatigue life prediction and engineering materials, applied in nuclear methods, chemical data mining, computer material science, etc., to achieve wide application, low cost, and high efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

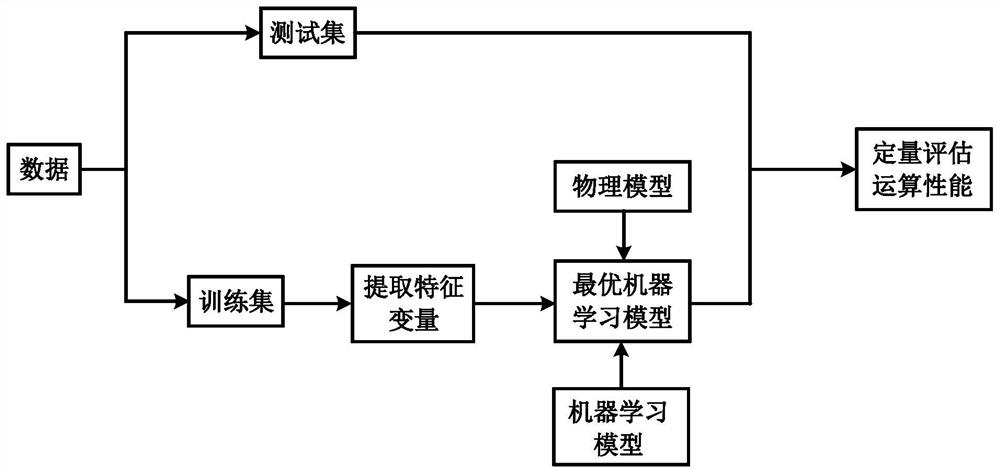

[0029] In the present invention, 25Cr2Ni2MoV steel, Ti6Al4V alloy and AlMgSi alloy welded joints are taken as examples, and the ultra-high cycle fatigue life prediction is carried out by means of a data-driven method, such as Figure 1-Figure 4 , the specific implementation steps are as follows:

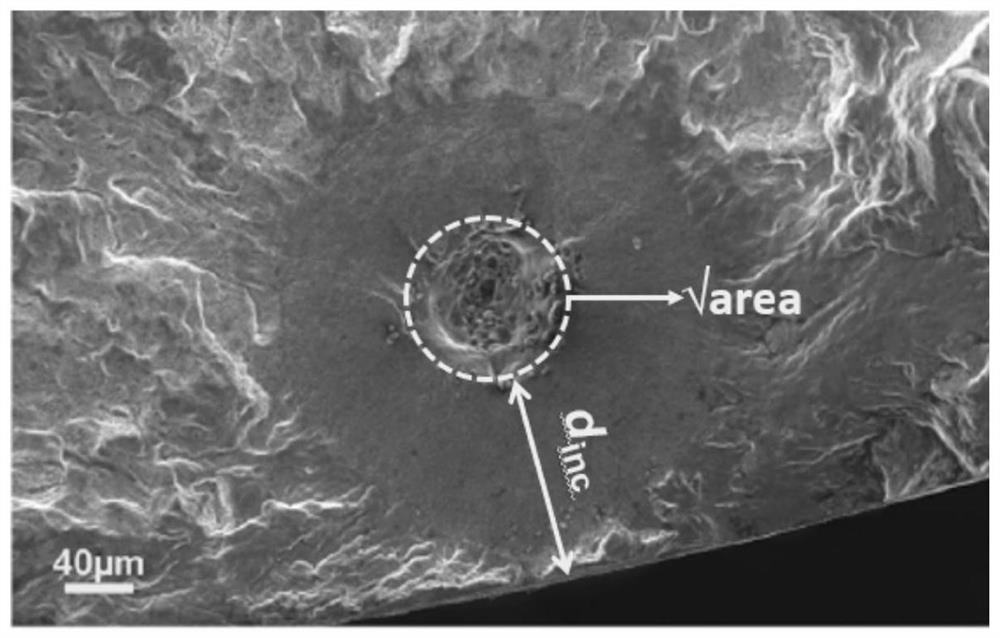

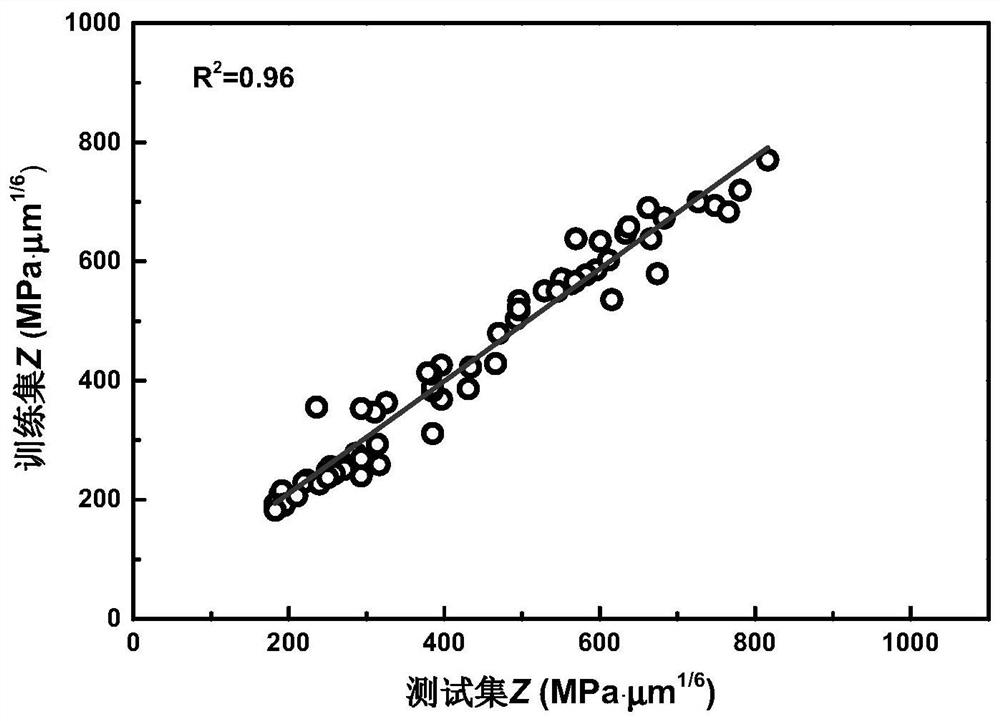

[0030] Step S1: collect the material information of the welded structure and the ultra-high cycle fatigue life data as the test set and the training set respectively, and perform ten-fold cross-validation on them; One part is used as training data, one part is used as test data, and the test is carried out, and the R obtained by comparing the test set obtained by 10 experiments with the training set 2 As a metric for evaluating data-driven performance. Each fatigue life data set includes the geometric characteristics of material defects, fatigue test conditions parameters, corresponding fatigue life and the intermediate calculation value Z based on the physical model p ;

[0031] ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com