Multi-channel DC motor drive control system based on cpld

A DC motor and drive control technology, which is applied in the direction of controlling multiple DC motors, can solve the problems of large circuit board area, many discrete components, and low scalability, and achieve low design and manufacturing costs, strong confidentiality, and flexible programming Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

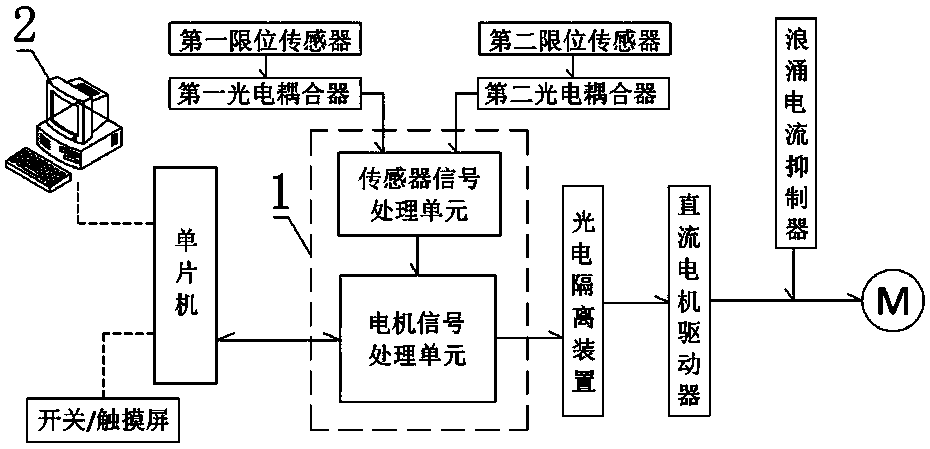

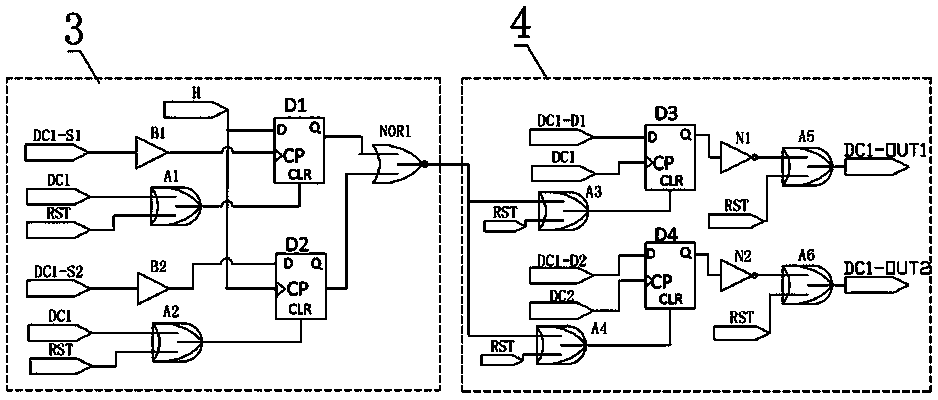

[0013] Such as figure 1 , 2 As shown, the CPLD-based multi-channel DC motor drive control system of the present invention includes 16 controlled DC motors M, and each of the DC motors M is provided with a device for limiting forward rotation and / or reverse rotation The first limit sensor and the second limit sensor; the forward rotation and / or reverse rotation of each DC motor are respectively controlled by a drive circuit, and the structure of the drive circuit of each DC motor is the same, and the DC motor Driver (full-bridge DC motor driver IC TB6643KQ), photoelectric isolation device, CPLD control unit 1 and single-chip microcomputer (STM32F10 series); the communication interface of the CPLD control unit communicates with the single-chip microcomputer, and the single-chip microcomputer communicates with the upper control computer 2 The input control end of the DC motor driver is connected with the output control end of the photoelectric isolation device, and the input con...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com