Tailing pond major safety risk quantification method

A technology of safety risk and quantification method, applied in the field of quantification of major safety risks in tailings ponds, can solve the problems of lack of empirical testing, risk assessment and control research, and lack of dynamic risk assessment, so as to achieve targeted perception, enhanced safety risk awareness, The effect of reducing blindness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

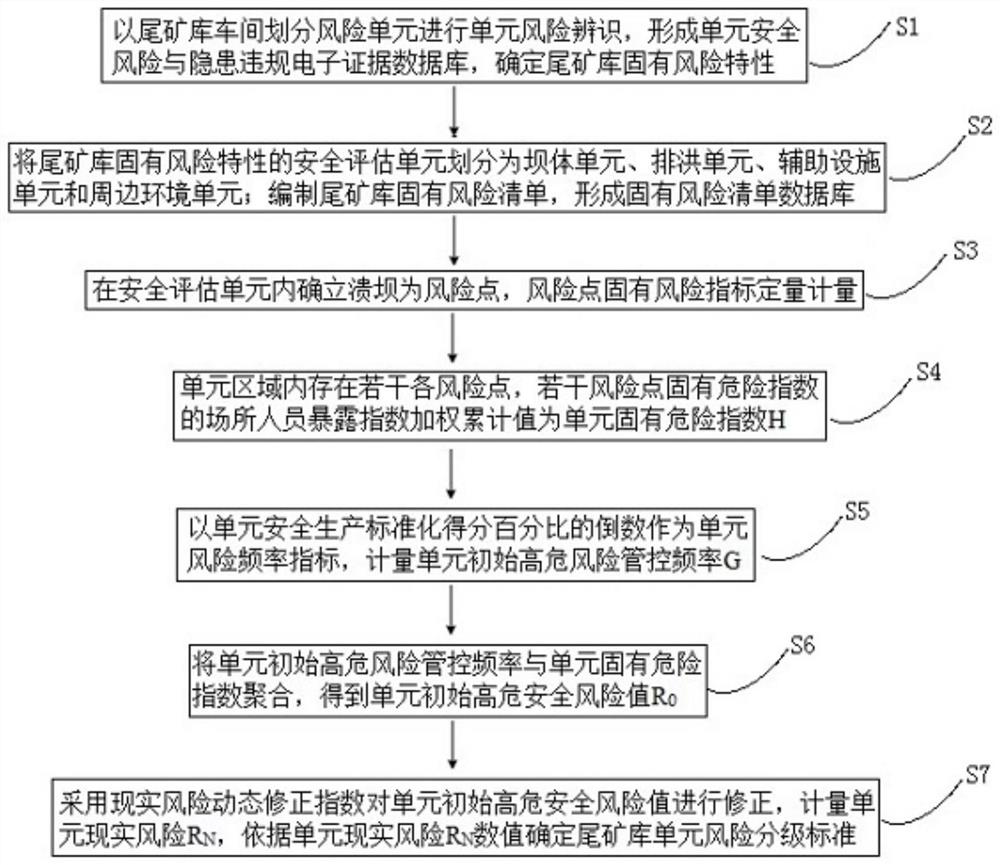

Method used

Image

Examples

Embodiment

[0154] Example: Taking a tailings pond as an example, this method is used for risk quantification.

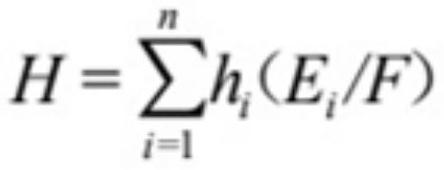

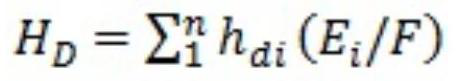

[0155] According to the relevant technical information provided by the company, the results of on-site investigation and analogy investigation, and the characteristics of the tailings pond system, on the basis of identification and analysis of dangerous and harmful factors, the risk point of the dam failure event is regarded as a unit of the entire system. Evaluate.

[0156] Dam unit major risk assessment.

[0157](1) High-risk equipment (h s )——dam body.

[0158] The tailings pond is a valley-type tailings pond (valley-bottom tailings pond), the dam building method is an upstream tailings dam, and the tailings stockpiling method is a wet stockpiling method.

[0159] The corresponding relationship between the intrinsically safe level of the dam body and the risk index is shown in the table below.

[0160]

[0161] (2) High risk process (K 1 )——monitoring monitoring sy...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com