Dispensing system having a mechanical amplifier

A distribution system and amplifier technology, applied in the direction of generators/motors, devices for coating liquid on the surface, piezoelectric effect/electrostrictive or magnetostrictive motors, etc., can solve problems such as shortened life expectancy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] Apparatuses and methods for amplifying movement of piezoelectric actuators are disclosed. While the present disclosure provides examples utilizing piezoelectric movement, it should be understood that the amplification devices and methods disclosed herein may also be used to amplify other types of mechanical movement, such as pneumatic, hydraulic, elastic, or other suitable movement mechanisms.

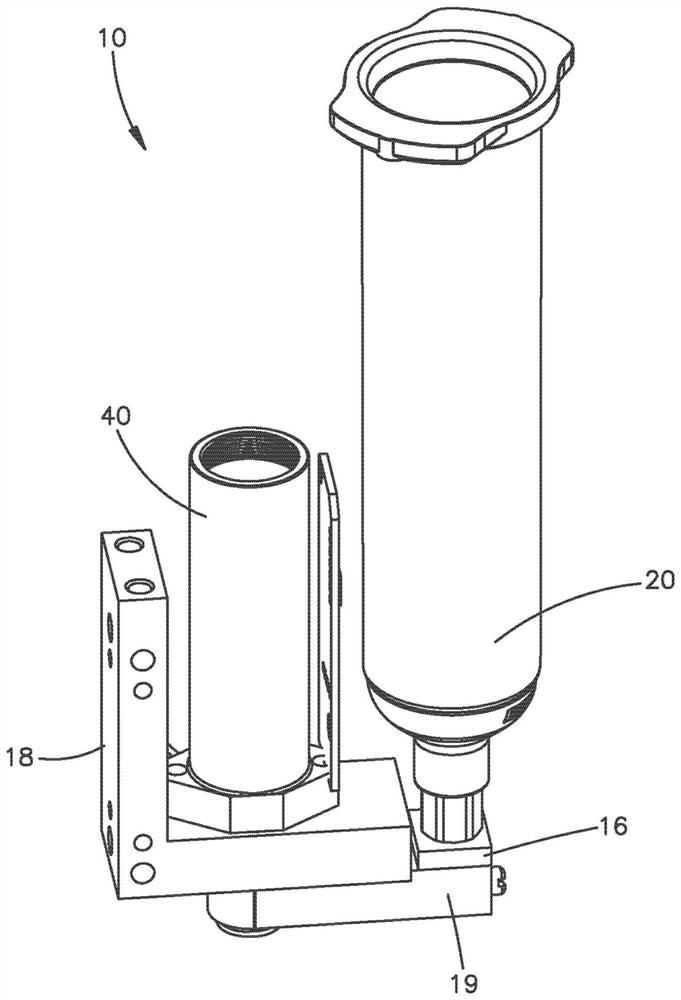

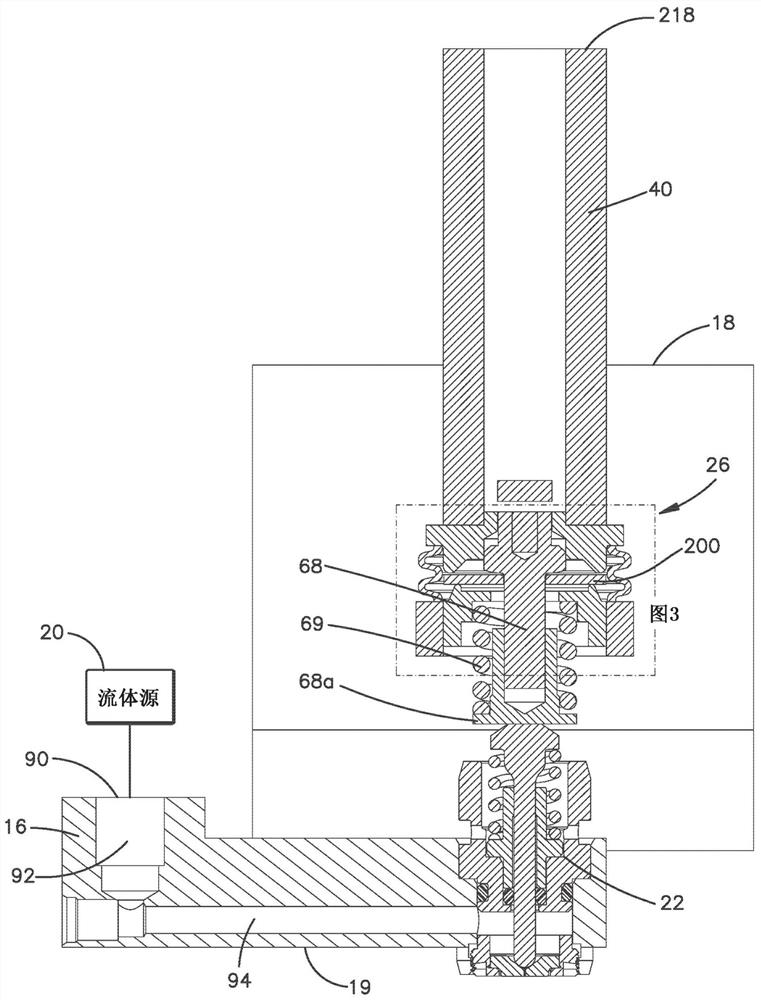

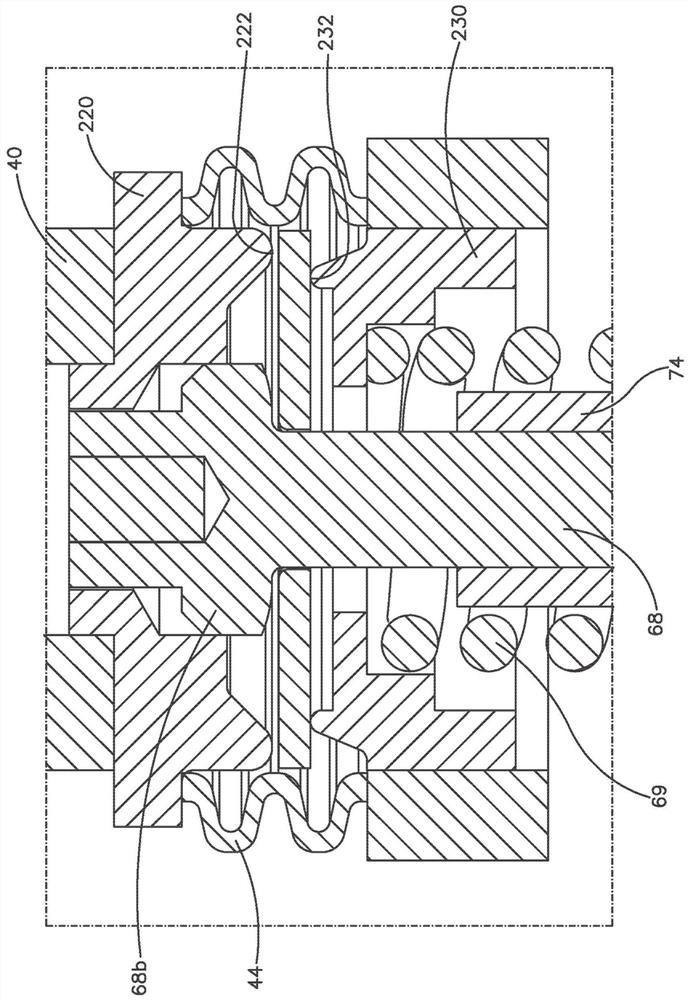

[0024] refer to Figure 1 to Figure 2 , shows dispensing system 10 having fluid body 16 coupled to actuator housing 18 . The fluid body 16 is held within a fluid body housing 19, which may include one or more heaters (not shown), depending on the needs of the application. The fluid body 16 is configured to receive fluid under pressure from a suitable fluid source 20 , such as a syringe barrel. Valve assembly 22 is coupled to housing 18 and extends into fluid body 16 . Mechanical amplifier 200 is coupled between piezoelectric actuator 26 and valve assembly 22, as will be descr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com