Integrated hydraulic robot connecting rod

A hydraulic robot and integrated technology, applied in the field of robotics, can solve the problems of single function, large volume and weight of hydraulic robot connecting rods, and achieve the effect of improving aesthetics, small size, and convenient maintenance and replacement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach

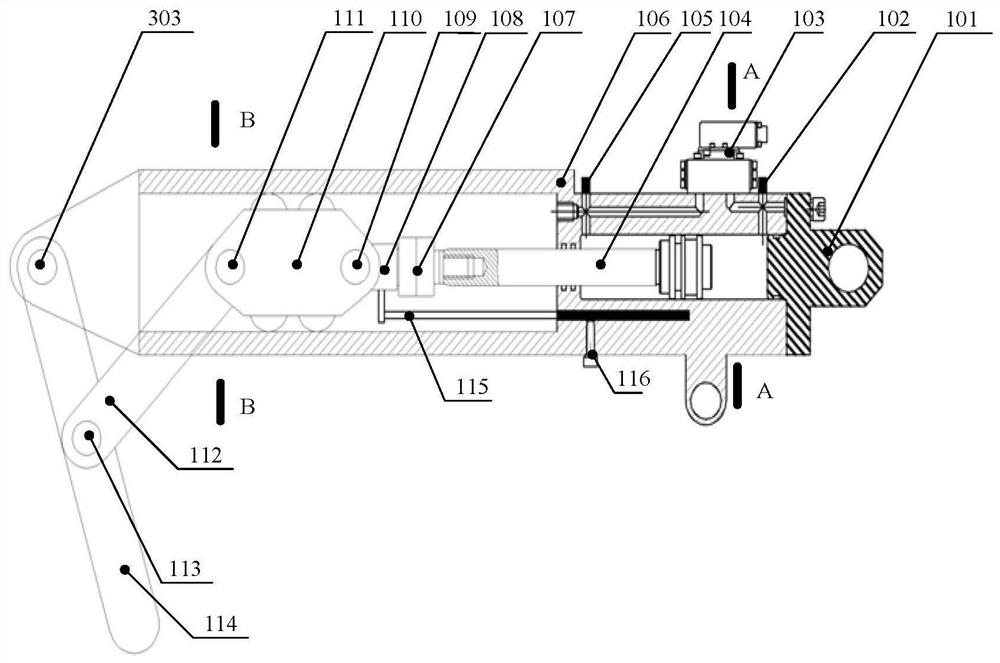

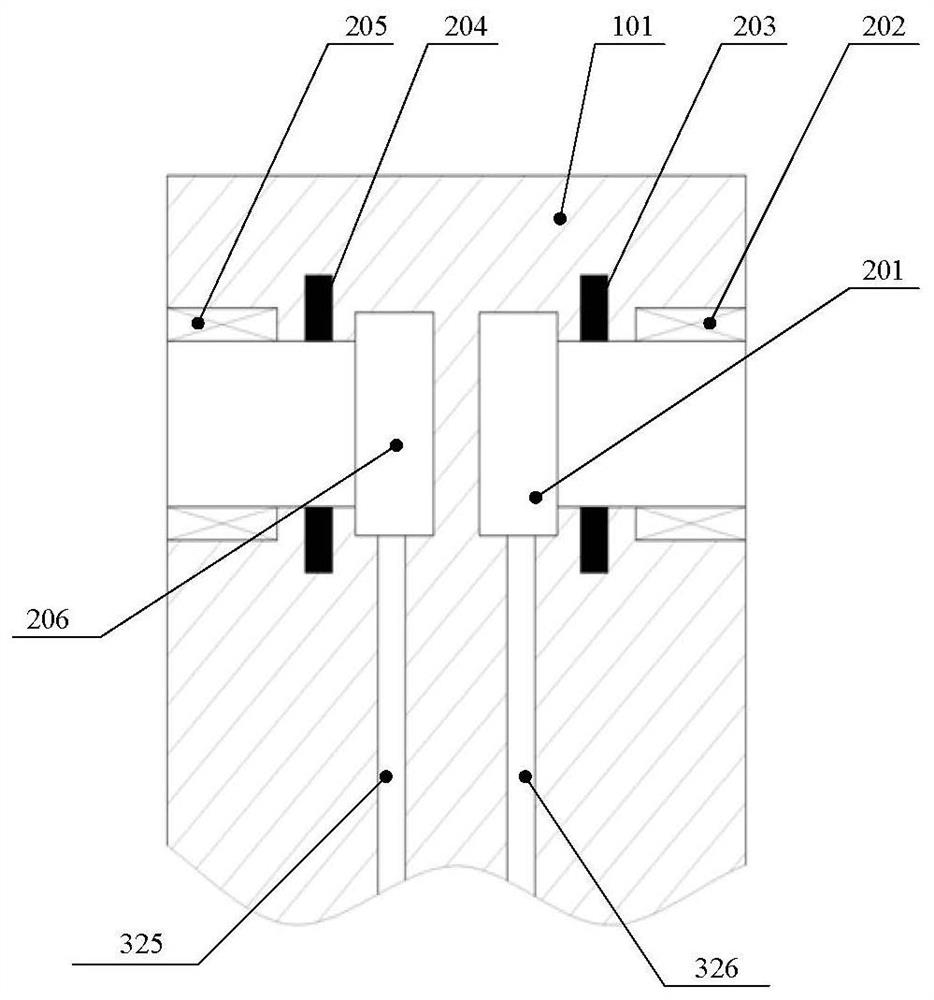

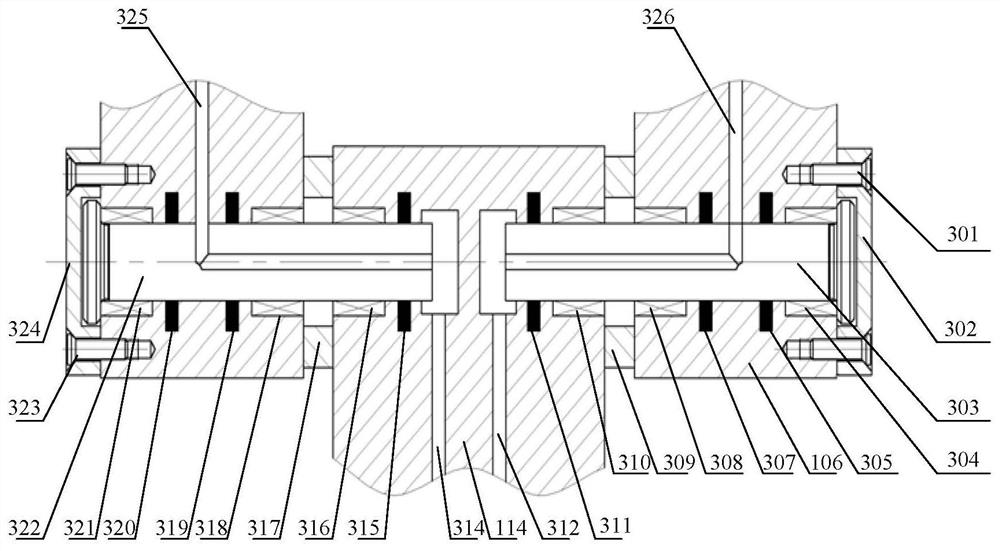

[0018] Specific implementation method: the following combination figure 1 and Figure 4 Describe the action process of the connecting rod of the integrated hydraulic robot. An integrated hydraulic robot connecting rod according to the present invention comprises connecting rod earrings (101), a liquid pressure sensor (102), a servo valve (103), a piston rod (104), a liquid pressure sensor (105), a connecting rod Body (106), one-dimensional force sensor (107), piston rod earring (108), connecting pin (109), guide slider (110), displacement sensor (116) and guide wheel (501), (502), (503), (504), (505), (506), (507), (508).

[0019] One end of the guide slider (110) is connected with the piston rod earring (108) through the pin shaft (109), and the piston rod earring (108) is connected with the one-dimensional force sensor (107) through threads, and the one-dimensional force sensor (107) the other end is connected with piston rod (104) by screw thread. Under the action of pr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com