In-box non-contact type digital painting and color developing all-in-one machine

A non-contact, digital inkjet technology, applied in typewriters, power transmission devices, printing devices, etc., can solve the problems that affect the processing effect of equipment and product quality, the ink marks on the finished printed cloth are blurred and messy, and the printing ink on the cloth escapes, etc. , to achieve the effects of improving the fixing effect, improving the drying effect and improving the processing quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

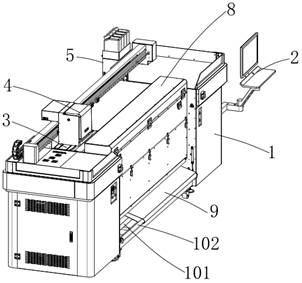

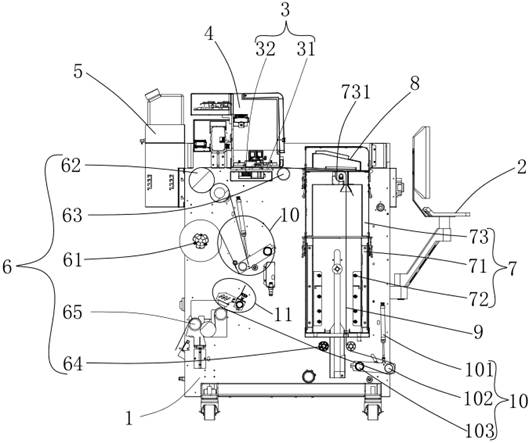

[0031] This example figure 1 and figure 2 As shown, the non-contact digital printing and coloring all-in-one machine in the box, the structure of the present invention is as follows: it includes a frame 1 and a controller 2, the frame 1 provides the load-bearing and the installation basis for each component, and the controller 2 includes electrical and other control systems And PLC control chipset;

[0032] The upper surface of frame 1 is provided with negative pressure inkjet platform 3, to the mobile ink cart 4 of negative pressure inkjet platform 3 surface inkjet printing, to the multi-color ink stack 5 that supplies ink to mobile ink cart 4, mobile ink cart 4 of the present application consists of Guide rail, drag chain, motor, car body, ink cartridge, negative pressure ink bag and nozzle, etc., the specific structure can refer to the applicant’s previously declared and authorized patent, the patent number is CN202020267935.7;

[0033] The frame 1 is provided with a clo...

Embodiment 2

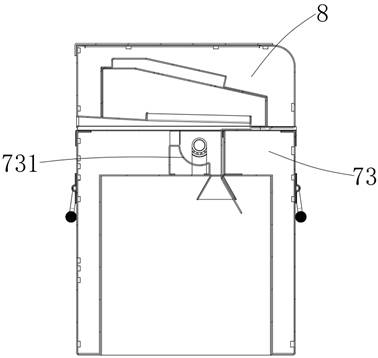

[0038] As shown in this embodiment, the cloth conveying roller assembly 6 includes the original cloth shaft 61, the cloth conveying rubber roller 62, the spray painting support pipe 63, and the box body cloth bearing pipe that are distributed sequentially along the advancing direction of the inkjet cloth 9 and are rotatably installed in the frame 1. 64 and the cloth receiving rubber roller 65, wherein, the cloth running rubber roller 62 and the inkjet printing support pipe 63 are respectively rotatably installed on the two ends of the negative pressure inkjet painting platform 3, and the box body supporting pipe 64 is arranged symmetrically and rotatably installed on the heating and coloring box 7 the discharge end.

[0039] The cloth running rubber roller 62, the inkjet support pipe 63, and the box body cloth support pipe 64 are in contact with the inner surface (non-painting surface) of the inkjet cloth 9. It is worth mentioning that: the box body cloth support pipe 64 is two...

Embodiment 3

[0043] This example image 3 As shown, the feed end of the cloth receiving rubber roller 65 is provided with a hot knife assembly 11, and the hot knife assembly 11 includes a hot knife guide rail 111, a knife seat 112 and an electric heating knife head 113, and the hot knife guide rail 111 is installed in the frame 1. A knife seat 112 is slidably installed on the hot knife guide rail 111 and locked by bolts, and the electric heating knife head 113 is installed in the knife seat 112 .

[0044] On the basis of the foregoing embodiments, the electric heating cutter head 113 can be used to cut the inkjet cloth 9, the mutual distance of a plurality of knife holders 112 on the hot knife guide rail 111 is the cutting width, and the electric heating cutter head 113 is used for cutting, on the one hand Efficiency is high, on the other hand prevents the thread ends of the cutting surface of the inkjet cloth 9 from being scattered, and improves the orderly effect of the side of the inkje...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com