Automobile air-inlet grille sealing assembly

A technology for air intake grilles and sealing components, which is applied to vehicle components, cleaning methods using tools, and arrangement of power plant cooling combinations, etc., can solve problems such as poor sealing effect, damage to sealing components, and easy accumulation of dust layers, etc. To achieve the effect of improving sealing performance and improving practicability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

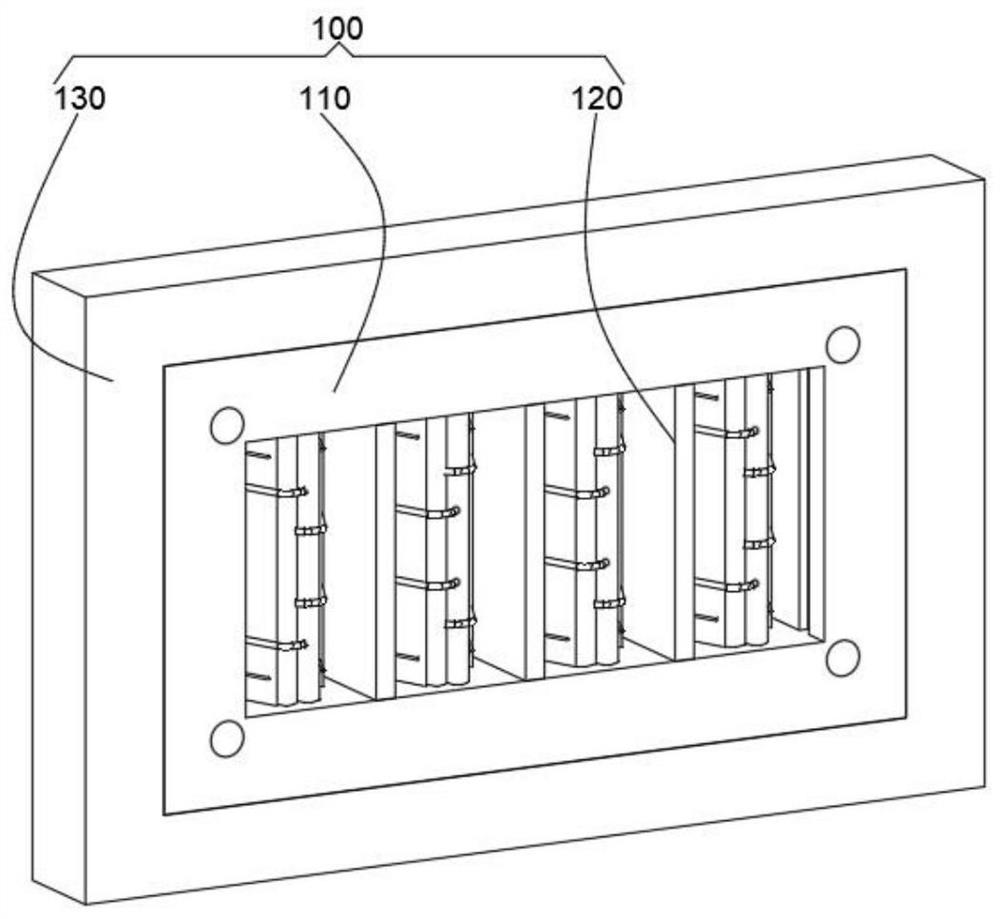

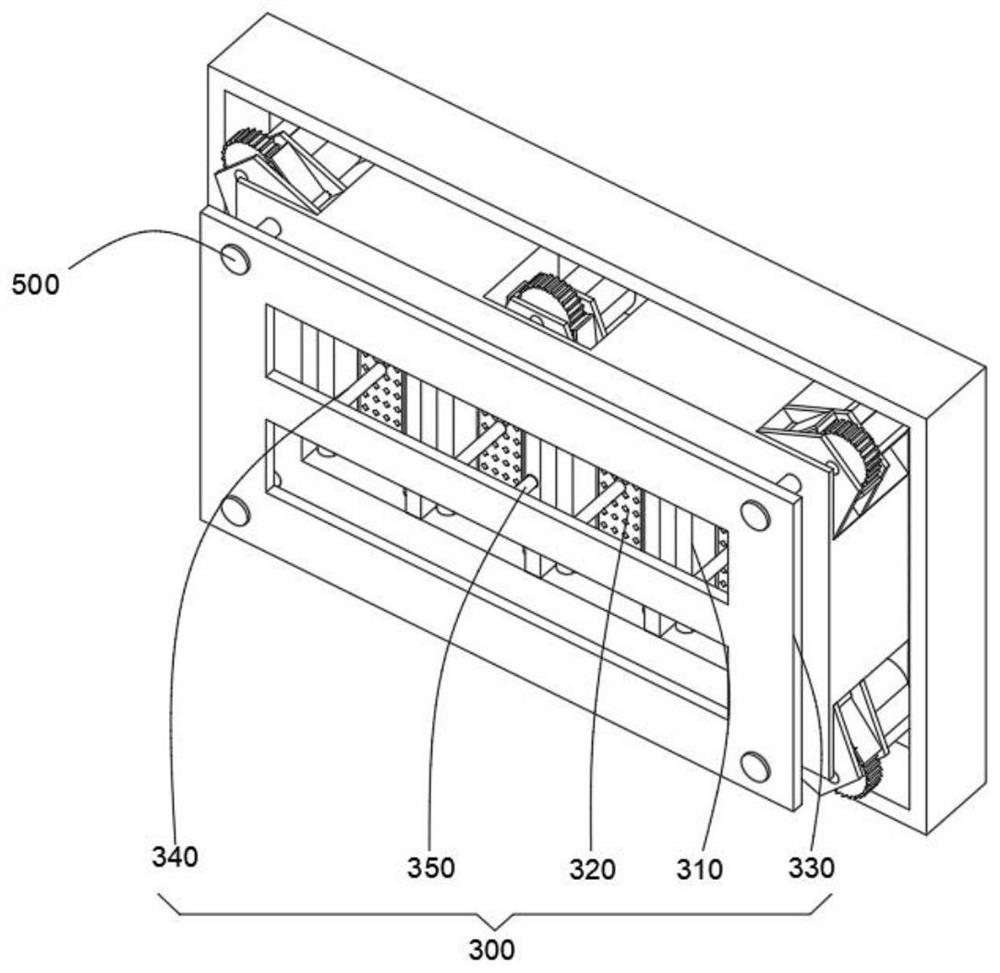

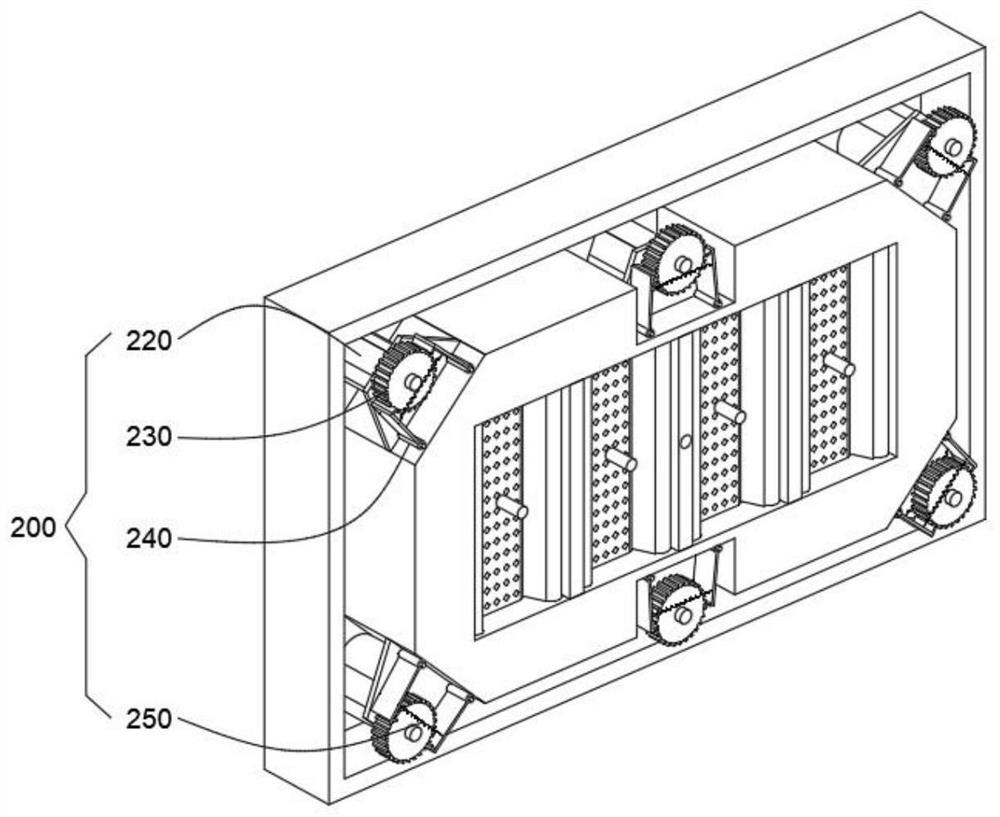

[0047] combine Figure 1-8As shown, a kind of automobile intake grill sealing assembly provided by the present invention includes a sealing module 100, a caulking module 200, an opening and closing module 300, and a cleaning module 400. The sealing module 100 includes a frame body 110 and is installed on the The partition 120 inside the frame body 110 and the rubber frame 130 sleeved on the outside of the frame body 110 are provided with a plurality of openings; the frame body 110 is the frame foundation of the entire structure, which is used for the entire The structure provides support, and it is also used to complete the docking with the air intake grille. On the one hand, the partition plate 120 plays the role of strengthening the frame body 110, and on the other hand, it is used to separate the multiple rotating plates 310, so that the sealing operation can be effective. Unfold, the rubber frame 130 is used to fill the gap generated between the present invention and the a...

Embodiment 2

[0058] combine Figure 1-3 As shown, on the basis of Embodiment 1, the cam 220 is located inside the rubber frame 130, the gear 230 is located at the rear side of the rubber frame 130, and the front and rear sides of the rubber frame 130 are provided with limiting plates 600. The positioning plate 600 is movably socketed on the outside of the rod body 210 and the bottom is fixedly connected to the bottom of the open cavity. The positioning plate 600 can limit the position of the gear 230 and the clamping plate 240, and improve the firmness of the caulking module 200 structure to a certain extent. sex.

Embodiment 3

[0060] combine figure 2 As shown, in the above embodiment, a plurality of T-shaped bars 500 are installed on the rear side of the frame body 110, and the plurality of T-shaped bars 500 are all enclosed on the outside of a plurality of rotating plates 310, and the T-shaped bars 500 are movable Through the plate body 330, the T-shaped bar 500 is used to provide support for the plate body 330, reduce the load of the plate body 330 on the electric push rod 350, and make the plate body 330 move more smoothly.

[0061] The working principle and application process of the present invention: when the present invention is put into practical use, the frame body 110 is initially connected to the air intake grille through the socket, wherein the rubber frame 130 is located between the frame body 110 and the air intake grille, Then turn the gear 230 clockwise, the gear 230 drives the cam 220 to rotate through the rod body 210, until the cam 220 presses the rubber frame 130 against the air...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com