Muddy soil unwatering and dewatering system and method with ground excitation and boosting matched with vacuum wells

A silty soil, press-fit technology, applied in the fields of geological engineering, geotechnical engineering, dewatering engineering, tunnel and underground construction engineering, can solve problems such as deformation of the enclosure structure, muddy foundation pit site, subsidence of excavators, etc. The effect of safe foundation pit construction, increasing hydraulic gradient, and speeding up the drainage process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] The present invention will be described in detail below in conjunction with the accompanying drawings and specific embodiments.

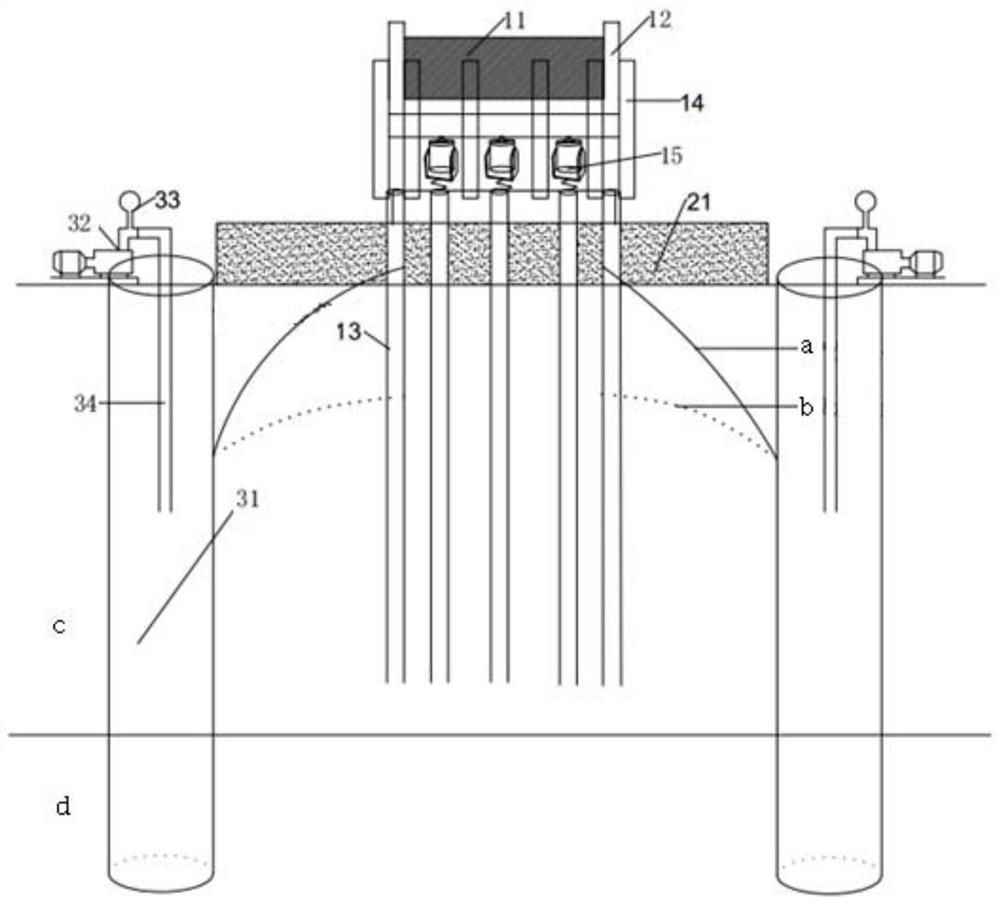

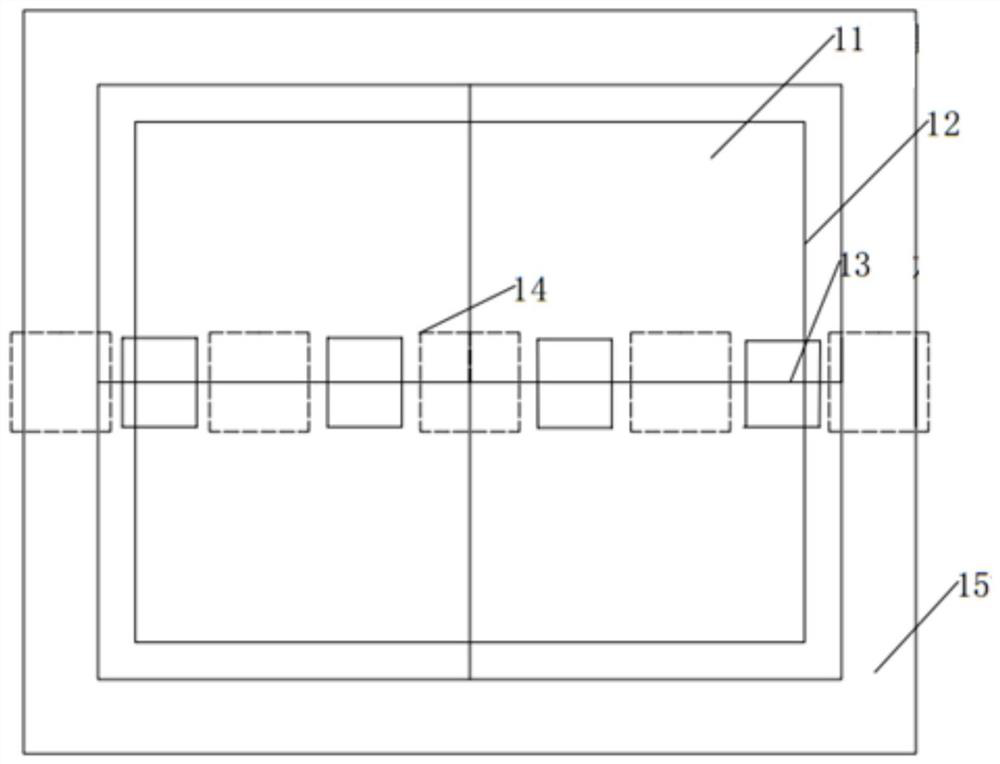

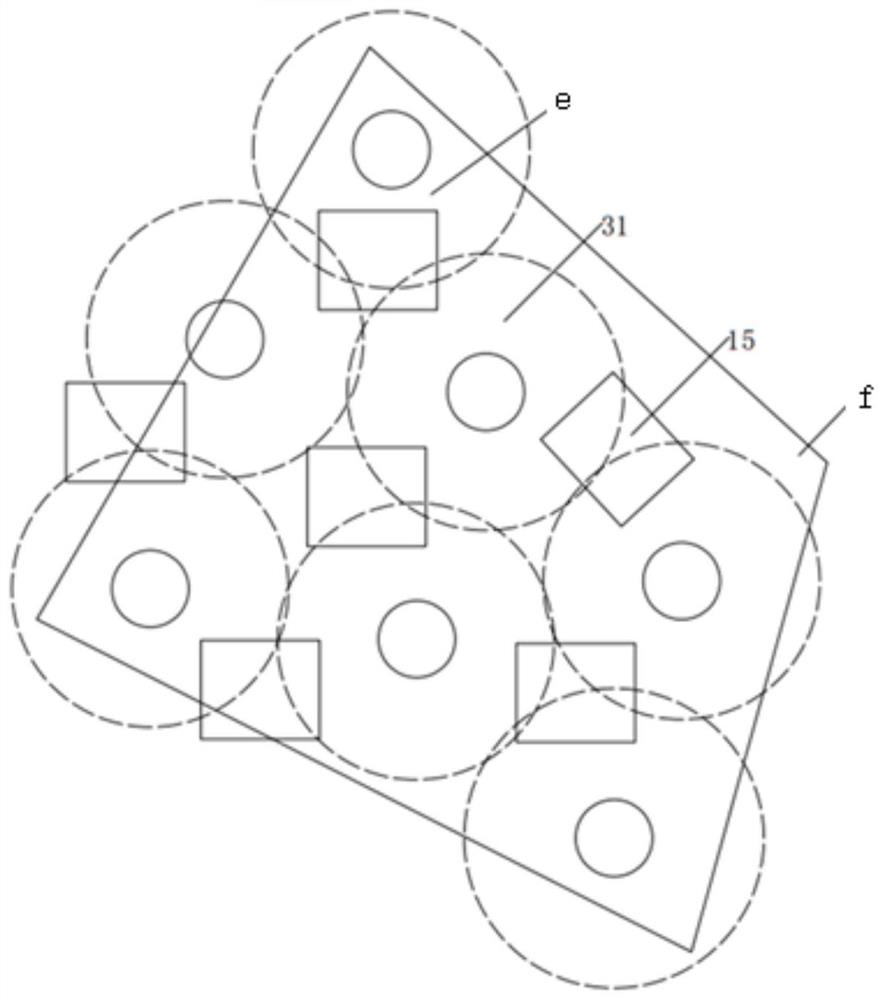

[0031] Such as figure 1 , 2 , 3, a kind of muddy soil dewatering and dewatering system with ground excitation boosting and vacuum well is arranged in the foundation pit for dewatering and dewatering of muddy soil in the pit, including several vacuum drainage wells 31 arranged in the foundation pit and located in the foundation pit. The vibration booster between adjacent vacuum drainage wells 31, the vibration booster includes a vibrator 15 and a force transmission pipe 13 located at the bottom of the vibrator 15, the force transmission pipe 13 is a round pipe, and the lower part is inserted into the soil Among them, the vibration generated by the exciter 15 is transmitted to the deep muddy soil layer through the force transmission pipe 13 and generates excess pore pressure, which can increase the remote pore water pressure of the underlying ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com