Electric cylinder with gas buffer

A technology of gas cushioning and electric cylinder, which is applied in the direction of electric components, electromechanical devices, electrical components, etc., can solve the problems of loss of shock absorbing buffer, short service life of rubber shock absorbing pad, rupture of rubber shock absorbing pad, etc., to prevent impact, To overcome the effect of shorter service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0044] The present invention will be further described in detail below in conjunction with the accompanying drawings, so that those skilled in the art can implement it with reference to the description.

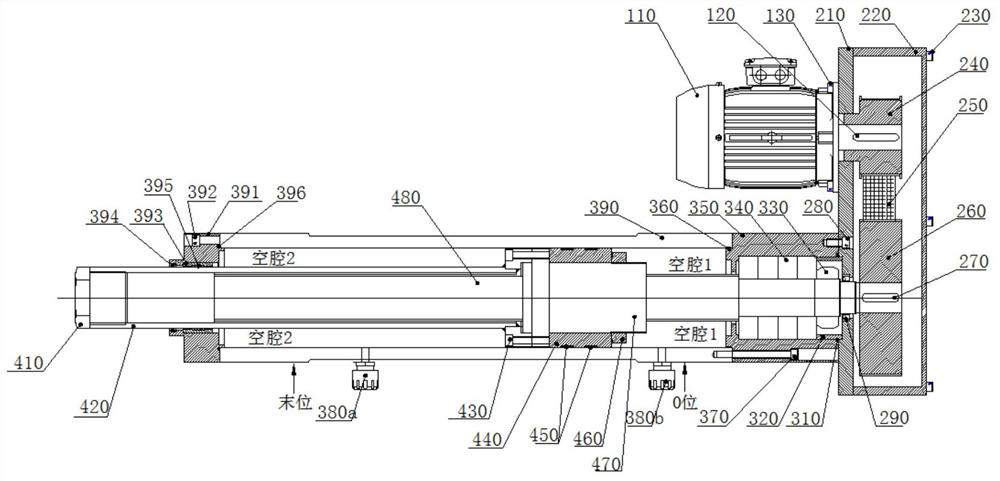

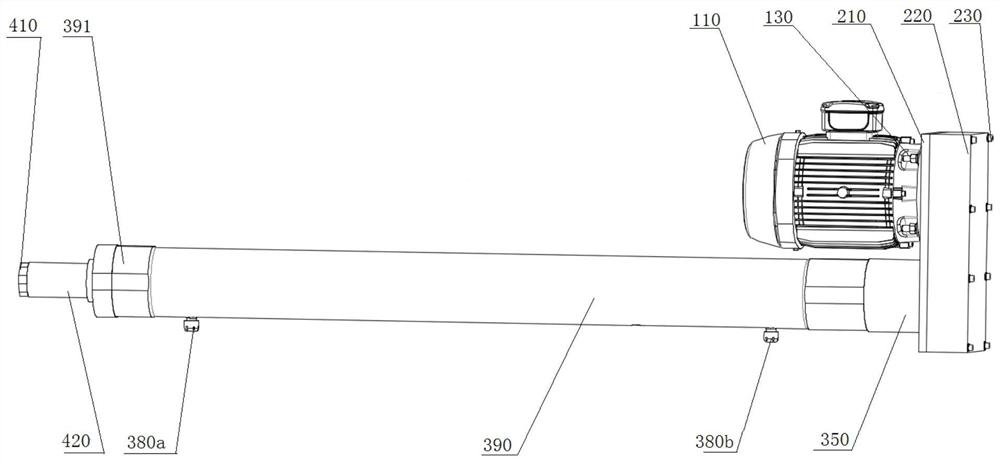

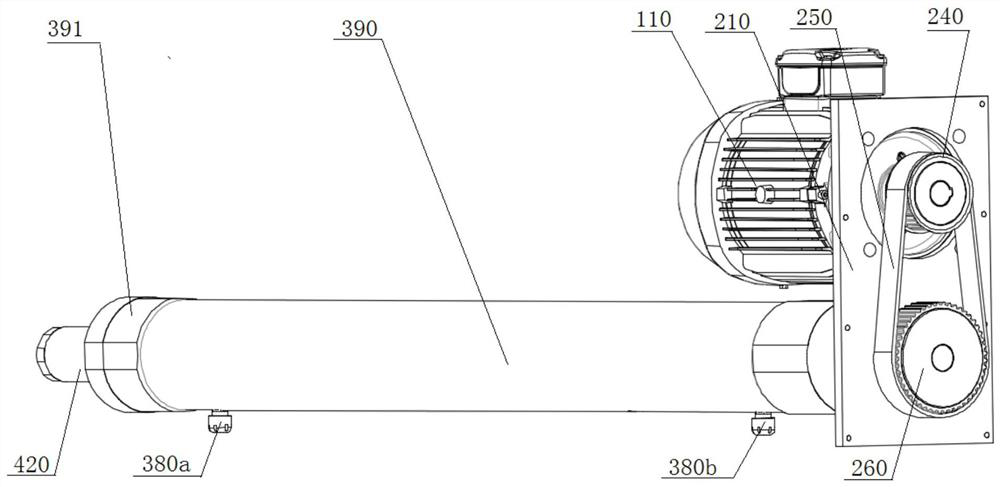

[0045] like Figure 1-5 As shown, the present invention provides an electric cylinder with a gas buffer, including: a driving motor 110; a first flat key 120; a first screw 130; a motor mounting plate 210; a reduction housing 220; a second screw 230; Synchronous wheel 240; synchronous belt 250; driven synchronous wheel 260; second flat key 270; third screw 280; oil seal 290; first O-ring 310; bearing pressure sleeve 320; bearing nut 330; bearing 340; bearing chamber 350 the second O-ring 360; the fourth screw 370; the first waterproof and ventilating plug 380a; the second waterproof and ventilating plug 380b; the outer tube 390; the front end cover 391; the fifth screw 392; The second support wear-resistant guide belt 395, the third O-ring 396; the front joint 410; the power...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com