Anti-leakage method for bathroom hardware connecting piece

A connector and anti-leakage technology, applied in the field of anti-leakage, can solve problems such as difficult to disassemble

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

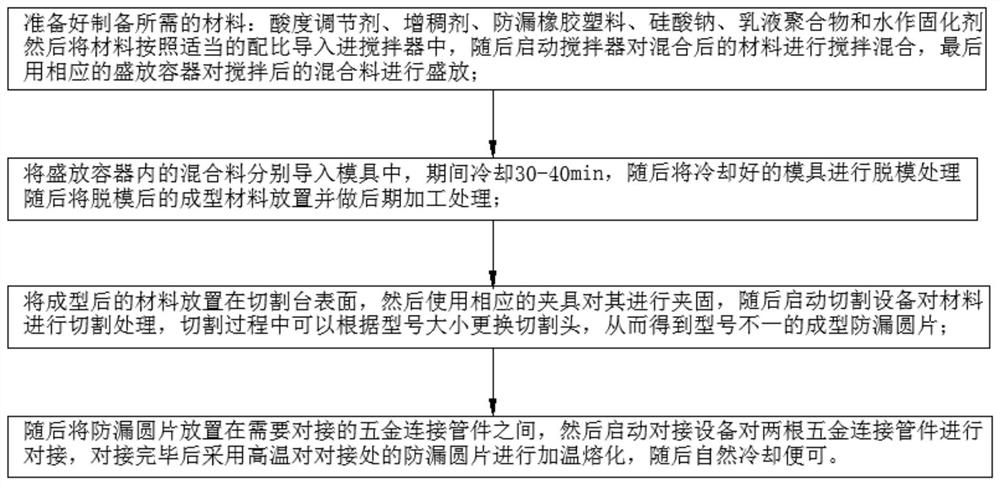

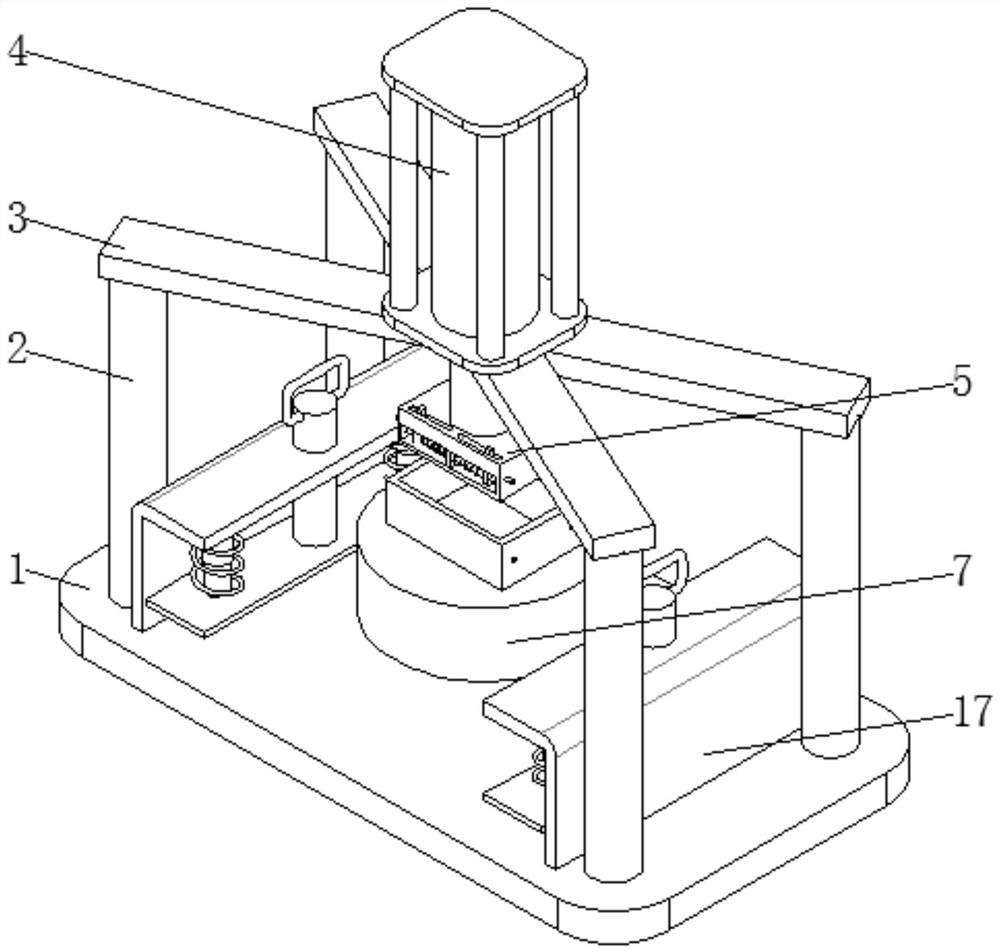

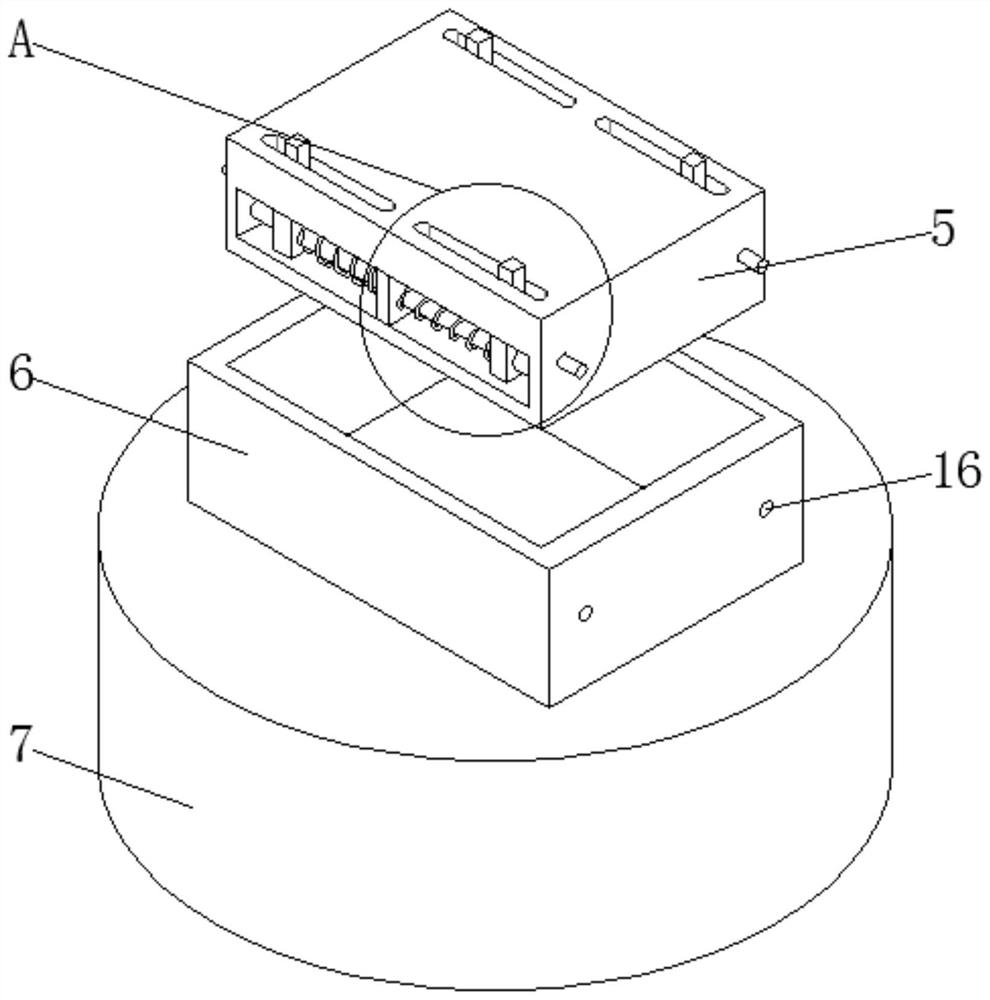

[0031] see Figure 1-5 , the present invention provides the following technical solutions: a method for preventing leakage of bathroom hardware connectors, comprising the following steps:

[0032] S1. Prepare the materials required for preparation: acidity regulator, thickener, leak-proof rubber plastic, sodium silicate, emulsion polymer and water as curing agent; then import the materials into the mixer according to the appropriate ratio, Then start the agitator to stir and mix the mixed materials, and finally, use the corresponding holding container to hold the stirred mixture;

[0033] S2. Import the mixed materials in the holding container into the mold respectively, cool for 30-40 minutes during the period, then demould the cooled mold, and then place the molded material after demoulding and do post-processing;

[0034] S3. Place the formed material on the surface of the cutting table, then use the corresponding fixture to clamp it, and then start the cutting equipment t...

Embodiment 2

[0045] see Figure 1-5 , the present invention provides the following technical solutions: a method for preventing leakage of bathroom hardware connectors, comprising the following steps:

[0046] S1. Prepare the materials required for preparation: acidity regulator, thickener, leak-proof rubber plastic, sodium silicate, emulsion polymer and water as curing agent; then import the materials into the mixer according to the appropriate ratio, Then start the agitator to stir and mix the mixed materials, and finally, use the corresponding holding container to hold the stirred mixture;

[0047] S2. Import the mixed materials in the holding container into the mold respectively, cool for 30-40 minutes during the period, then demould the cooled mold, and then place the molded material after demoulding and do post-processing;

[0048] S3. Place the formed material on the surface of the cutting table, then use the corresponding fixture to clamp it, and then start the cutting equipment t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com