Flue and boiler

A flue and boiler technology, applied in the field of flue, can solve the problems of high replacement cost, slag splashing, violent converter reaction, etc., and achieve the effect of simple structure, convenient replacement and convenient operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

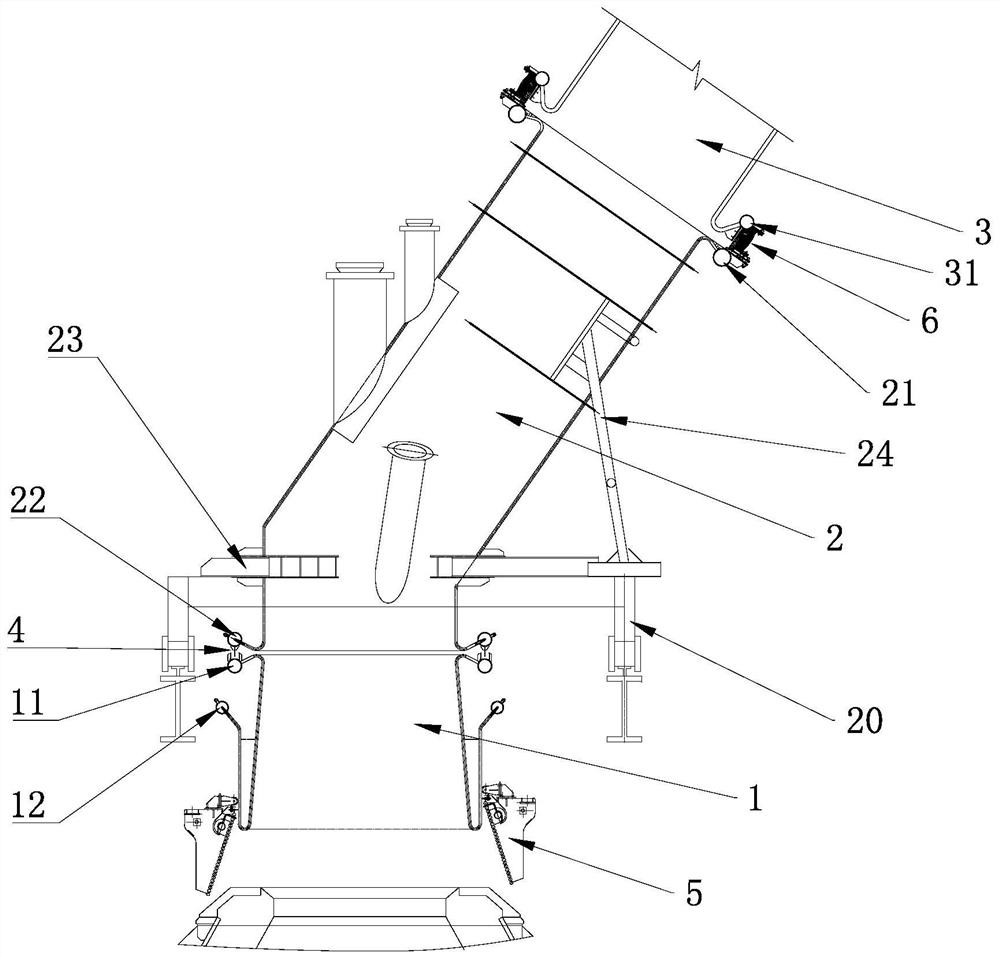

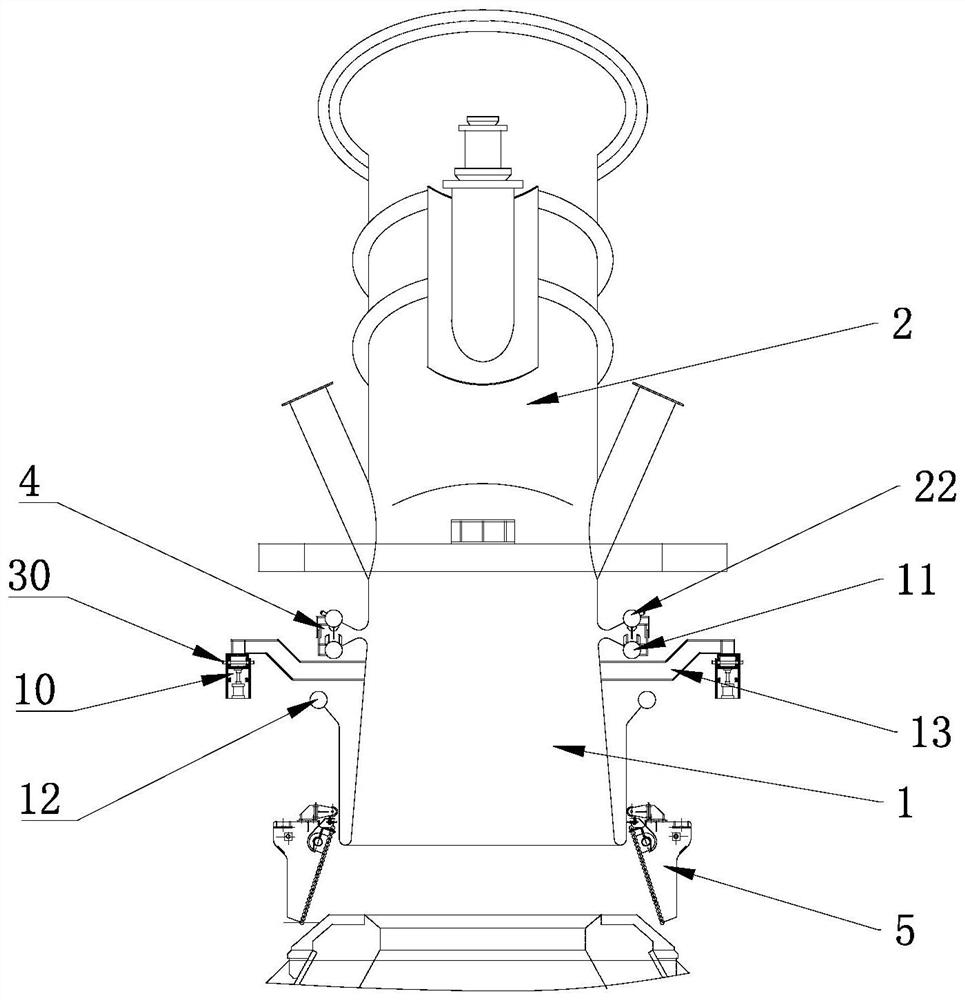

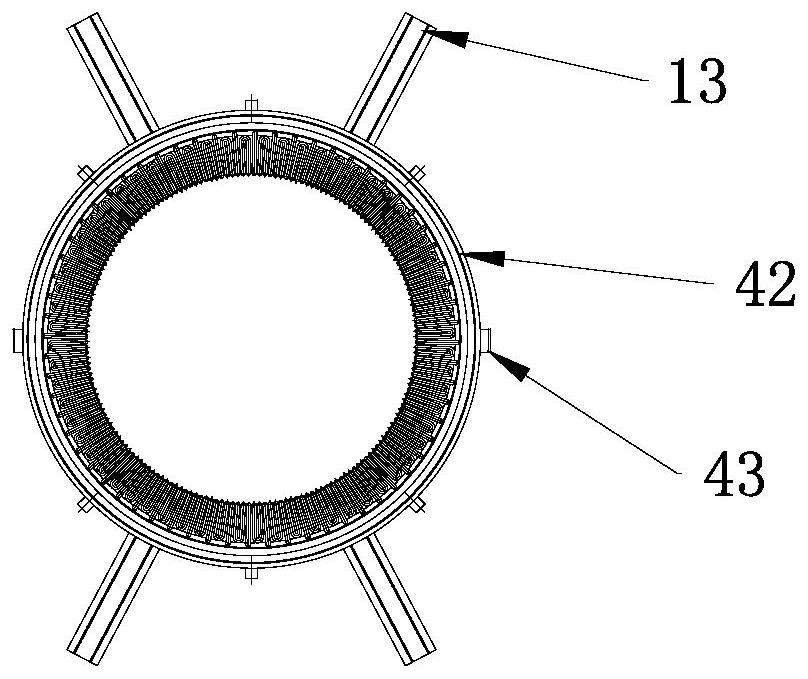

[0030] refer to Figure 1 to Figure 6 As shown, as a preferred embodiment of the present invention, a flue is provided, including a furnace mouth section flue and a main flue 3, the furnace mouth section flue is segmented on the vertical section, and is divided into a furnace mouth fixed section flue Road 1 and flue 2 of the moving section of the furnace mouth. During steelmaking, a large amount of waste gas and dust overflow from the converter mouth. First, the waste gas and dust are collected by the movable fume hood 5, and then enter the dust removal system and recovery system through the flue above the movable fume hood 5. In this embodiment, the direction of the fixed-section flue 1 in the fixed use state is used as the description direction, that is, the side facing the ground is the bottom side, and the other side away from the bottom side is the top side, which are located at the same time. On the elevation and perpendicular to the top and bottom sides are the front a...

Embodiment 2

[0040] This embodiment provides a boiler, preferably, the boiler is a converter waste heat boiler boiler, including a boiler and a flue, the flue is the flue provided in Embodiment 1, and the flue is arranged on the top of the boiler.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com