Multi-product pulsation assembly line modeling and performance evaluation method

An assembly line and multi-product technology, which is applied in the field of modeling and performance evaluation of production systems, can solve the problems that simulation methods cannot provide general solutions, and achieve the effect of correct and effective aggregation methods, small deviation of results, and high degree of agreement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach

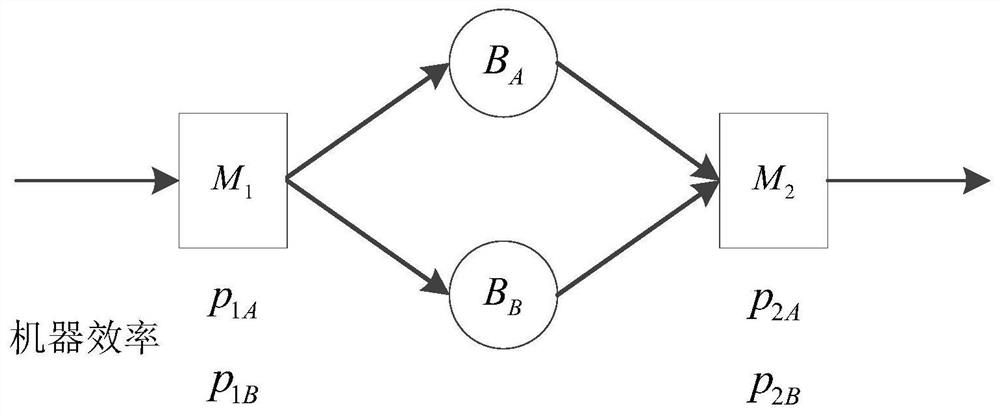

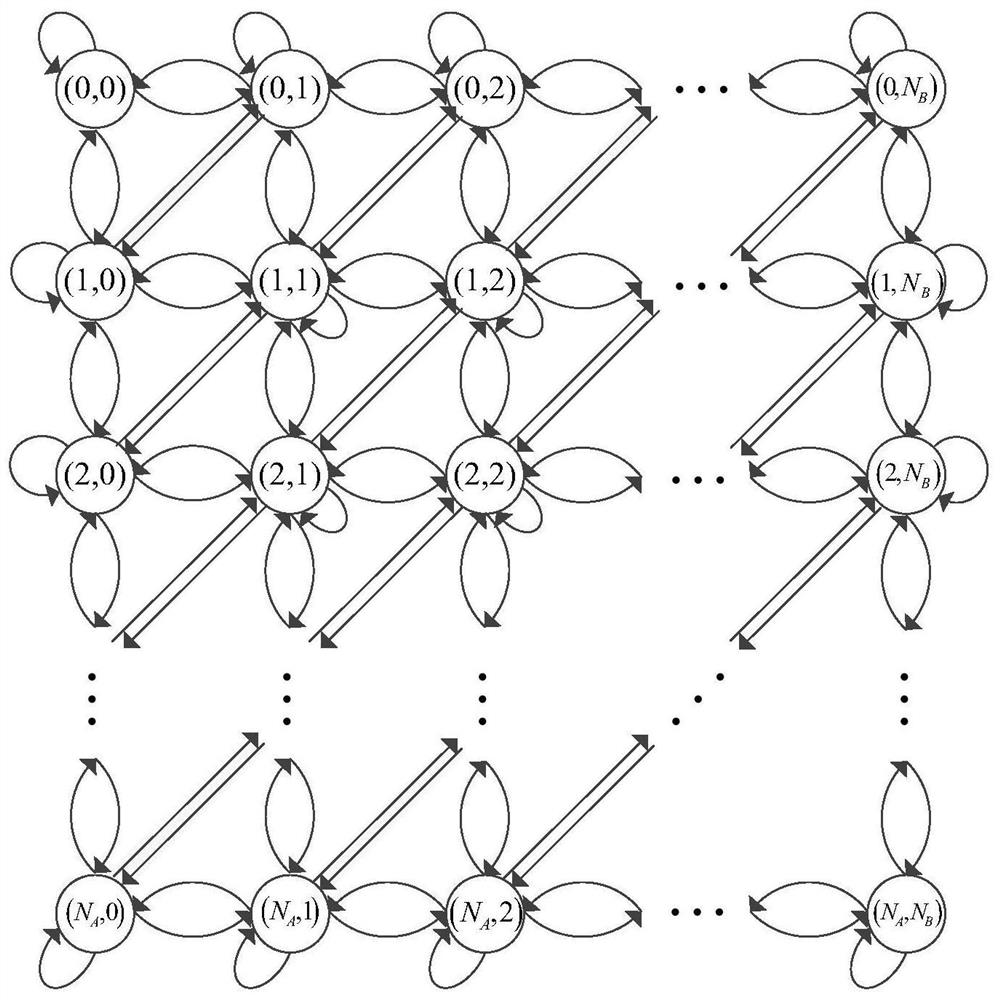

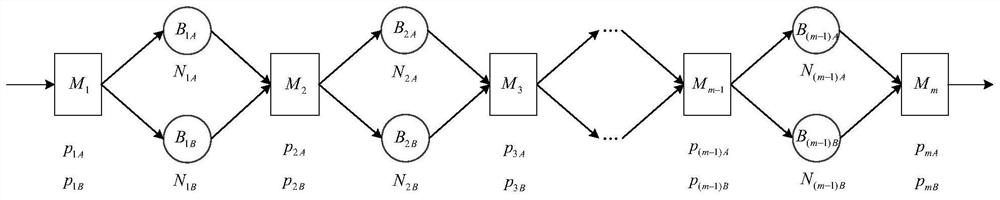

[0052] The invention proposes a performance evaluation method of a pulsating assembly line considering a buffer division strategy, and illustrates its effectiveness through simulation experiments. The specific process is as follows: First, a buffer segmentation strategy is proposed, and an analytical model is established based on the Markov model for the two-station pulsating assembly line considering the buffer segmentation strategy; secondly, the analytical model of the two-station pulsating assembly line is solved to obtain productivity, WIP Level, starvation rate and blocking rate and other performance indicators, and verify the effectiveness of the analytical model through simulation experiments; finally, for the multi-station pulsating assembly line considering the buffer segmentation strategy, an aggregation method is proposed to evaluate the performance of the production line, and the simulation experiment is used to verify the effectiveness of the method. The specific...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com