Supporting composite board and display module

A display module and composite board technology, which is applied in the direction of instruments, cooling/ventilation/heating renovation, electrical components, etc., can solve the problems of thick overall thickness, difficult to meet the light design requirements of display modules, etc., and achieve the overall thickness reduction. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

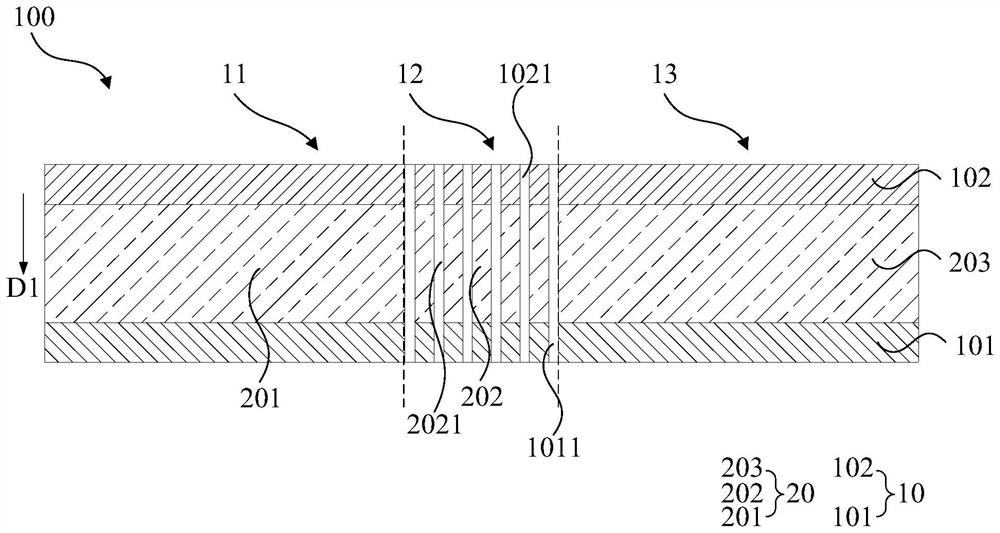

[0031] Such as figure 1 As shown, it is a schematic structural diagram of the support composite board 100 provided in the first embodiment of the present application; wherein, the support composite board 100 is applied to a foldable display panel, and the support composite board 100 includes a rigid support layer 10 and a heat dissipation layer 20; The rigid support layer 10 includes a first planar portion 11, a second planar portion 13 and a bent portion 12 between the first planar portion 11 and the second planar portion 13, and the heat dissipation layer 20 is embedded In the rigid support layer 10, the heat dissipation layer 20 includes a first heat dissipation portion 201 corresponding to the first planar portion 11, a second heat dissipation portion 203 corresponding to the second planar portion 13, and a The bridging portion 202 corresponding to the bent portion 12 , the first heat dissipation portion 201 and the second heat dissipation portion 203 are connected through...

Embodiment 2

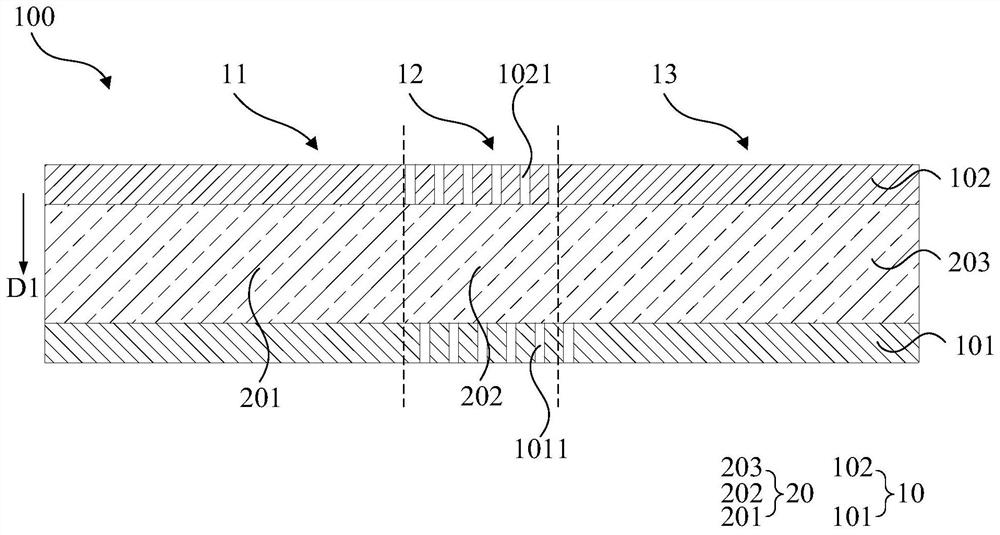

[0042] Such as figure 2 As shown, it is a schematic structural diagram of the supporting composite board 100 provided in the second embodiment of the present application; wherein, the structure of the supporting composite board 100 in the second embodiment of the present application is the same as that of the supporting composite board 100 in the first embodiment of the present application or Similar, the only difference is that the first opening 1011 runs through the first supporting layer 101 and exposes the surface of the heat dissipation layer 20 close to the first supporting layer 101, and the second opening 1021 runs through the The second support layer 102 exposes the surface of the heat dissipation layer 20 close to the second support layer 102; wherein, each of the first openings 1011 and each of the adjacent second openings 1021 are along the first opening 1021. One direction D1 is mutually misaligned.

[0043] In the second embodiment of the present application, o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com