Cogging torque compensation method of permanent magnet synchronous servo motor

A technology of cogging torque and servo motors, which is applied in the control of generators, motor generators, electronically commutated motors, etc., can solve the problems of low accuracy of discrete table lookup, heavy burden of precise modeling and calculation, and achieve Compensation speed is fast, the output pulsation is reduced, and the effect is good

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

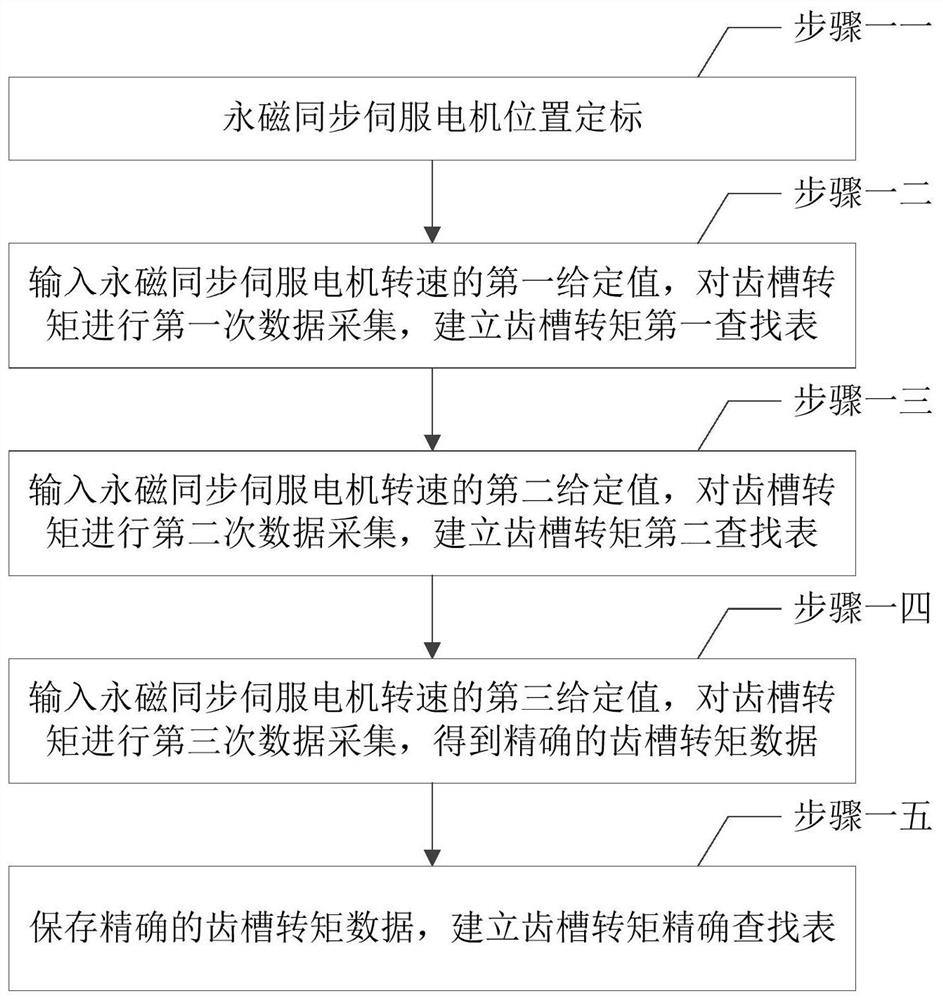

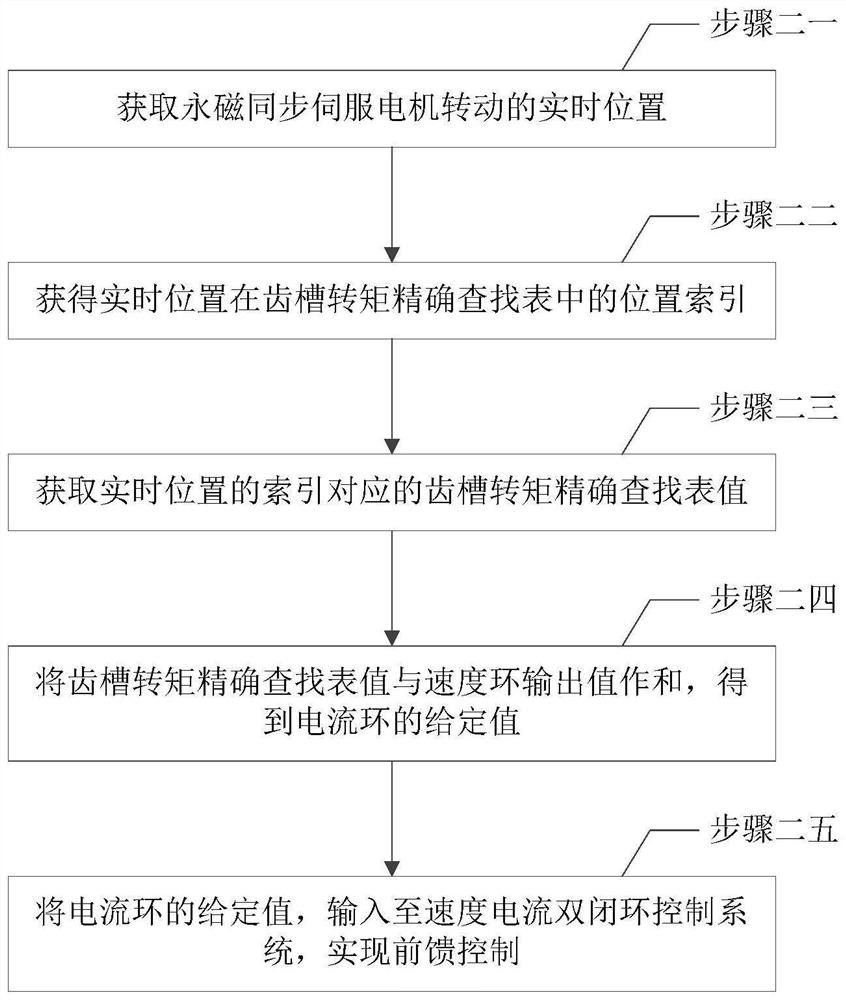

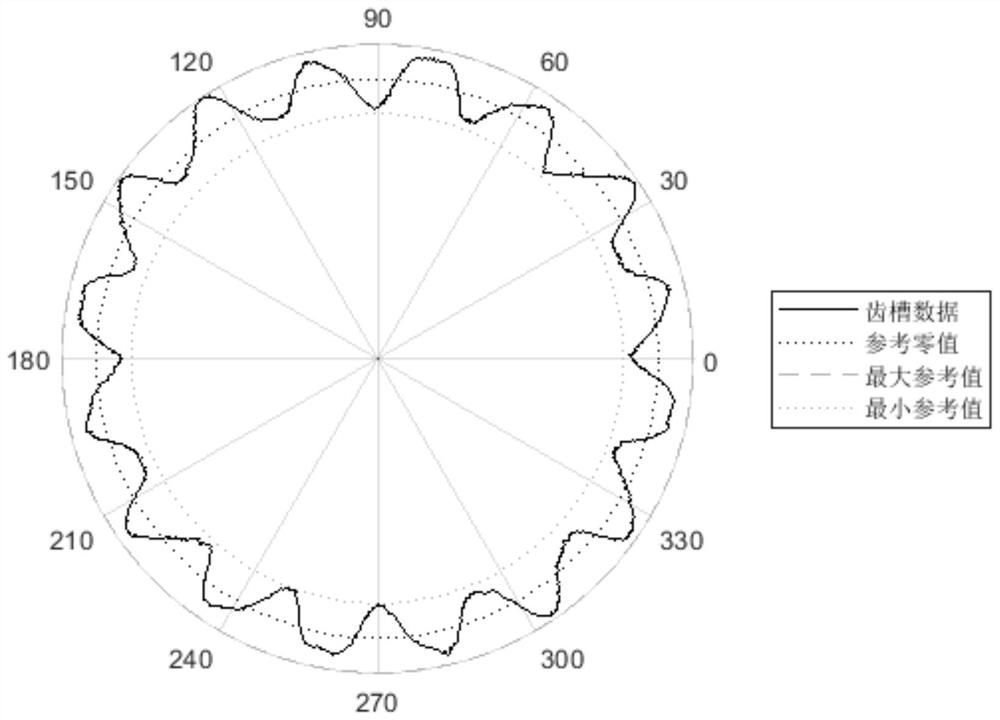

[0054] Specific implementation mode one: combine Figure 1 to Figure 4 Describe this embodiment, a permanent magnet synchronous servo motor cogging torque compensation method described in this embodiment, the compensation method includes the following steps:

[0055] Step 1. Collect the cogging torque data of the permanent magnet synchronous servo motor, obtain accurate cogging torque data, and establish an accurate cogging torque lookup table;

[0056] Step 2. Based on the precise cogging torque lookup table established in step 1, perform feed-forward control on the cogging torque of the permanent magnet synchronous servo motor to realize compensation for the cogging torque of the permanent magnet synchronous servo motor.

[0057] In this embodiment, the specific steps for establishing an accurate cogging torque lookup table in step 1 are:

[0058] Step 11, permanent magnet synchronous servo motor position calibration; used to obtain the initial position of the permanent mag...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com