Method and apparatus for recognizing the presence of leakages from sealed containers

A technology of sealing containers and containers, which is applied in the test of fluid tightness, by detecting the appearance of fluid at the leakage point, measuring devices and other directions, it can solve the problems that cannot be detected immediately and damage the product quality, so as to improve the recognition sensitivity and improve Effect of Measurement Sensitivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

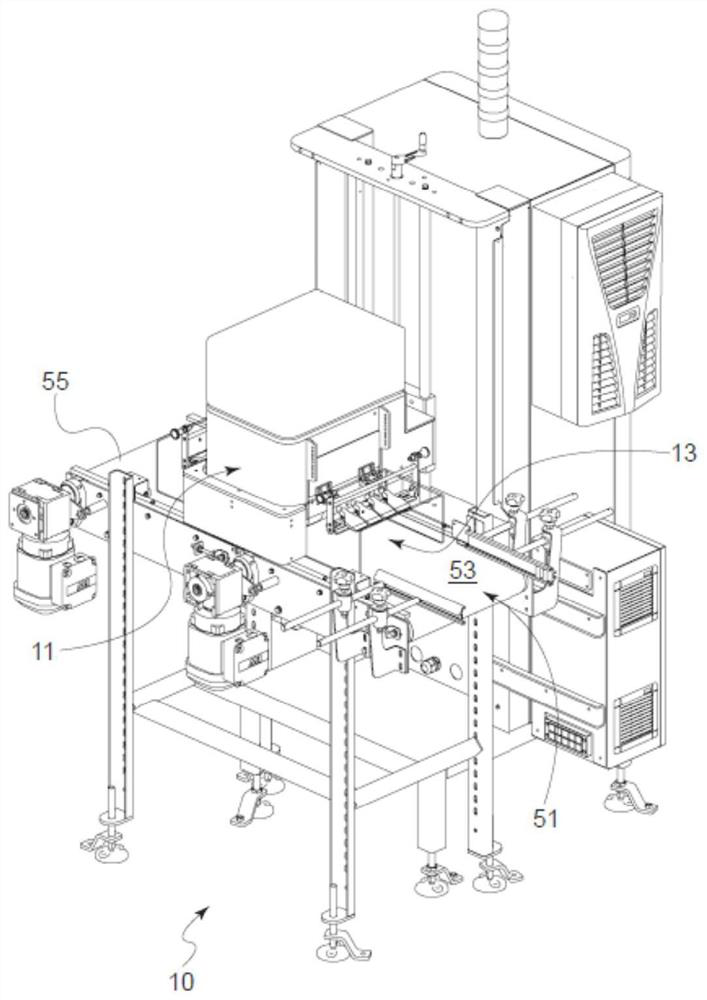

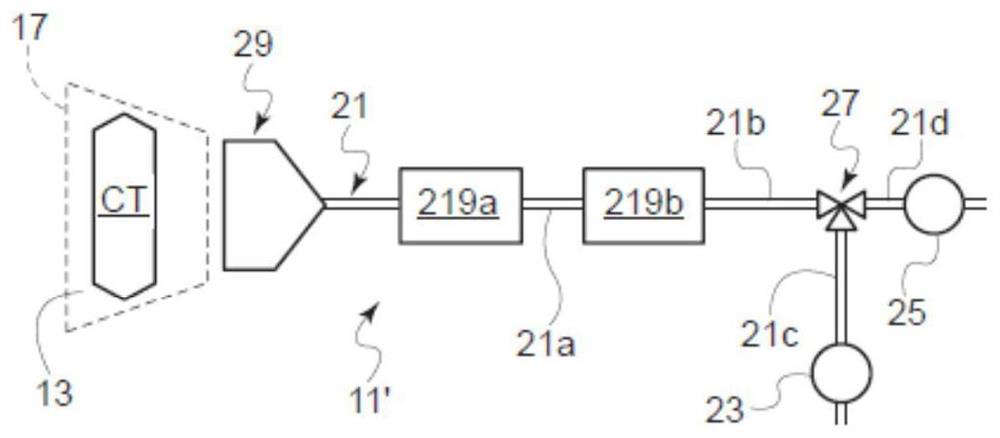

[0053] refer to figure 1 , according to the illustrated embodiment of the invention, the sample container to be tested is placed by the positioning assembly 51 in the detection zone 13 defined in the device 10 incorporating the device of the invention. According to this embodiment, the positioning assembly 51 comprises a pair of conveyor belts 53, 55 for introducing or bringing containers into the detection zone 13 and removing said containers from or exiting the detection zone 13, respectively. Preferably the positioning assembly 51 also includes a pair of side guides 55a, 55b for correct positioning of the container in the detection zone 13, preferably in the center of the zone 13.

[0054] Optionally, the method according to the invention comprises the step of subjecting the sample container to compression or crushing to facilitate possible gas escape. Preferably said pressing step is performed by means of a pressing assembly comprising rotatable rollers.

[0055] will no...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com