Gastrodia elata noodles and processing method thereof

A processing method and noodle technology, which is applied in the field of Gastrodia elata noodles and its processing, can solve problems such as broken bars, small bite strength, and no solution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0017] Example 1 Formula 1

[0018] Preparation: 1.5 kg of Gastrodia elata powder, 300 kg of flour, 10 kg of gluten powder, and 0.01 kg of glucose oxidase; the steps for making Gastrodia elata noodles are as follows: a. Making Gastrodia elata powder: soak fresh Gastrodia elata in cold water, wash and slice , dried in an oven at 55-60°C, and then crushed into 100-120 mesh black gastrodia elata powder for later use; b. Weigh the three raw materials of black gastrodia elata powder, gluten powder, and glucose oxidase in proportion, and mix them Finally, dissolve into an appropriate amount of iodine-containing salt and moisture; c, take flour, stir with the water that has added three kinds of raw materials of Gastrodia elata powder, gluten powder, and glucose oxidase and let it stand for 15 minutes; Processing and forming, drying, and packaging are finished products.

Embodiment 2

[0019] Example 2 Formula 2

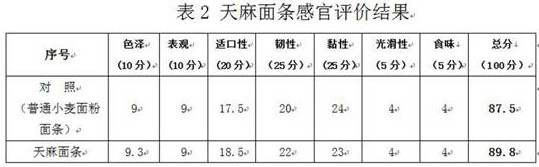

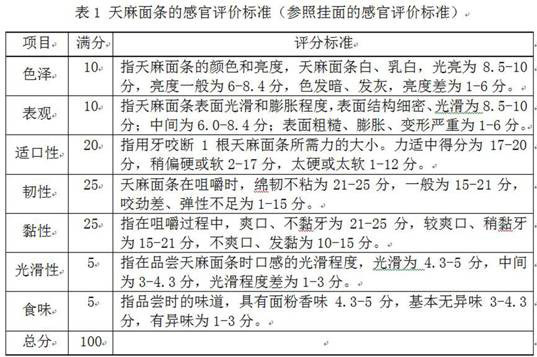

[0020] Prepare materials: 3 kilograms of Gastrodia elata powder, 600 kilograms of flour, 20 kilograms of gluten powder, and 0.02 kilograms of glucose oxidase; Dry it in an oven at 55-60°C, then crush it into 100-120 mesh black gastrodia elata powder for later use; b, weigh the three raw materials of black gastrodia elata powder, gluten powder and glucose oxidase in proportion, mix , dissolve into an appropriate amount of iodine-containing salt and water; c, weigh the flour, stir it with the water that has been added to the three raw materials of Gastrodia elata powder, gluten powder, and glucose oxidase and let it stand for 15 minutes; d. Forming, drying, packaging is the finished product. The total sensory evaluation score of Gastrodia elata noodles samples made with this formula ratio is 89.8 points, and the scoring results are shown in Table 2 (the sensory evaluation standards of Gastrodia elata noodles are shown in Table 1), it can be seen tha...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com