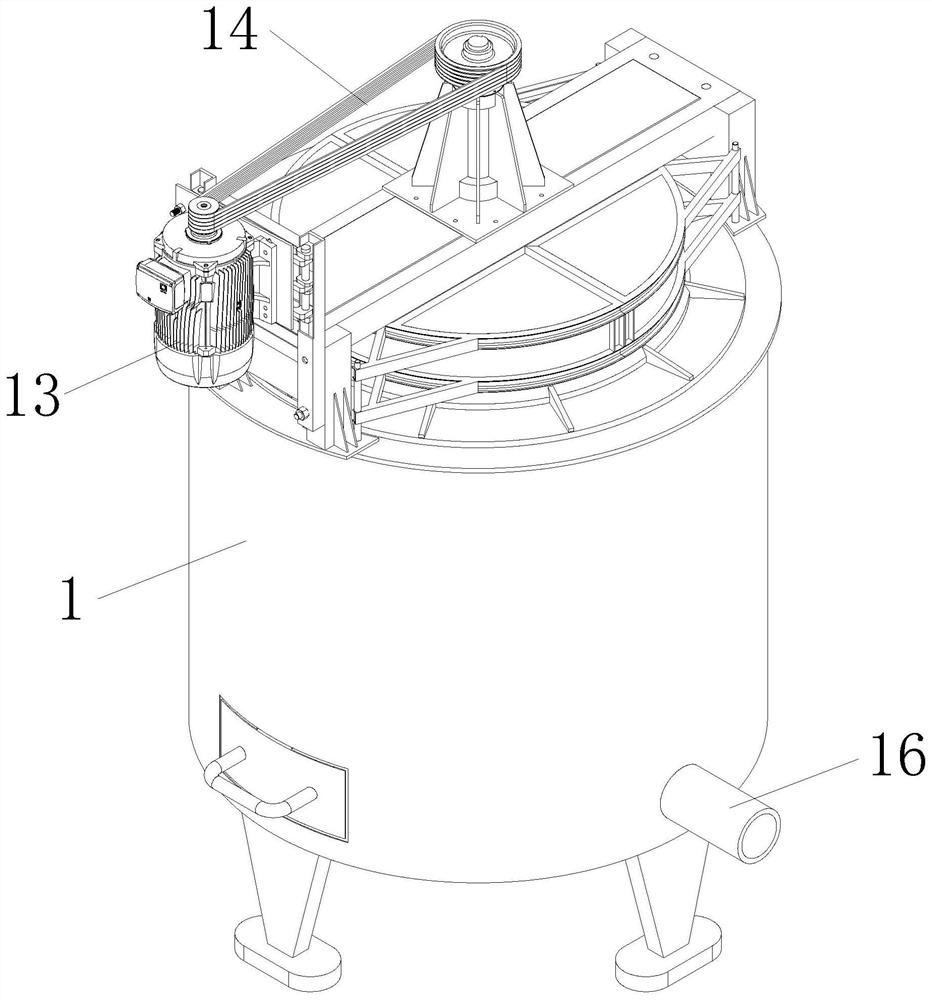

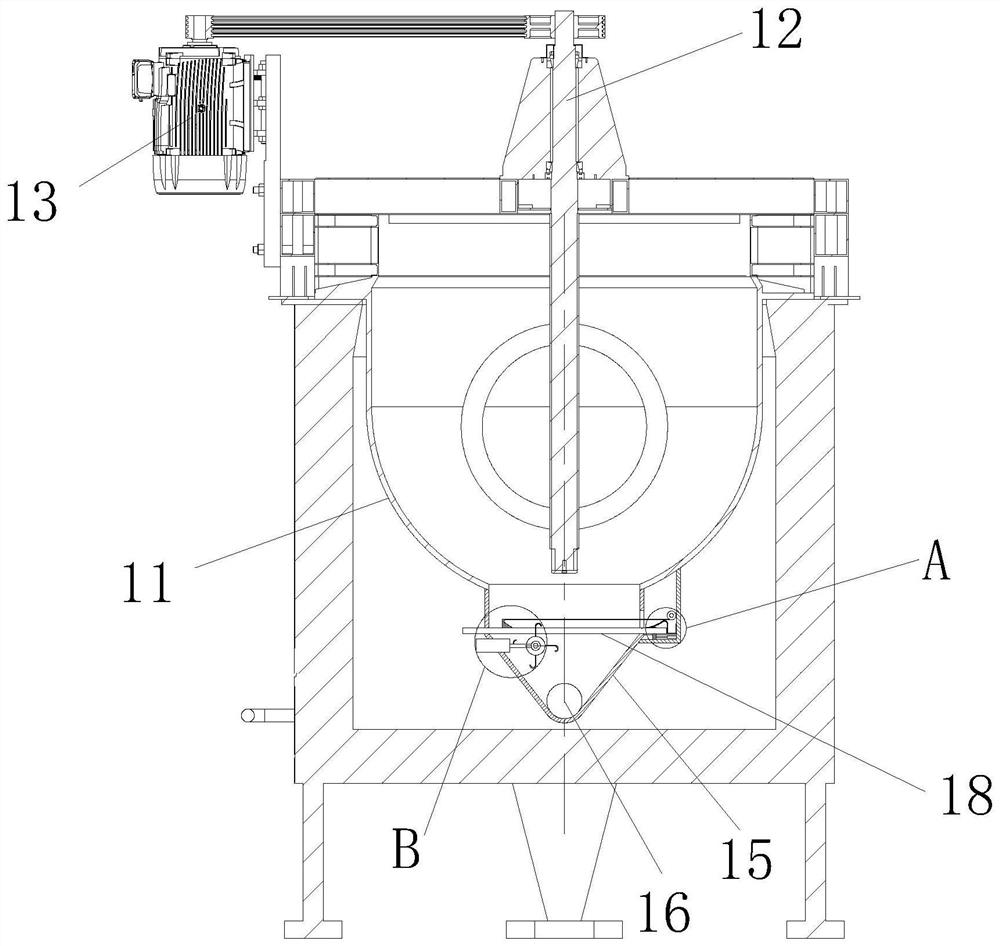

Waterborne epoxy floor paint production equipment

A technology for epoxy floor paint and production equipment, which is applied in the directions of separation method, cleaning method using liquid, cleaning method and utensils, etc. Reduce the adhesion of impurities on the hook surface, avoid downtime for disassembly and cleaning, and ensure smooth effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

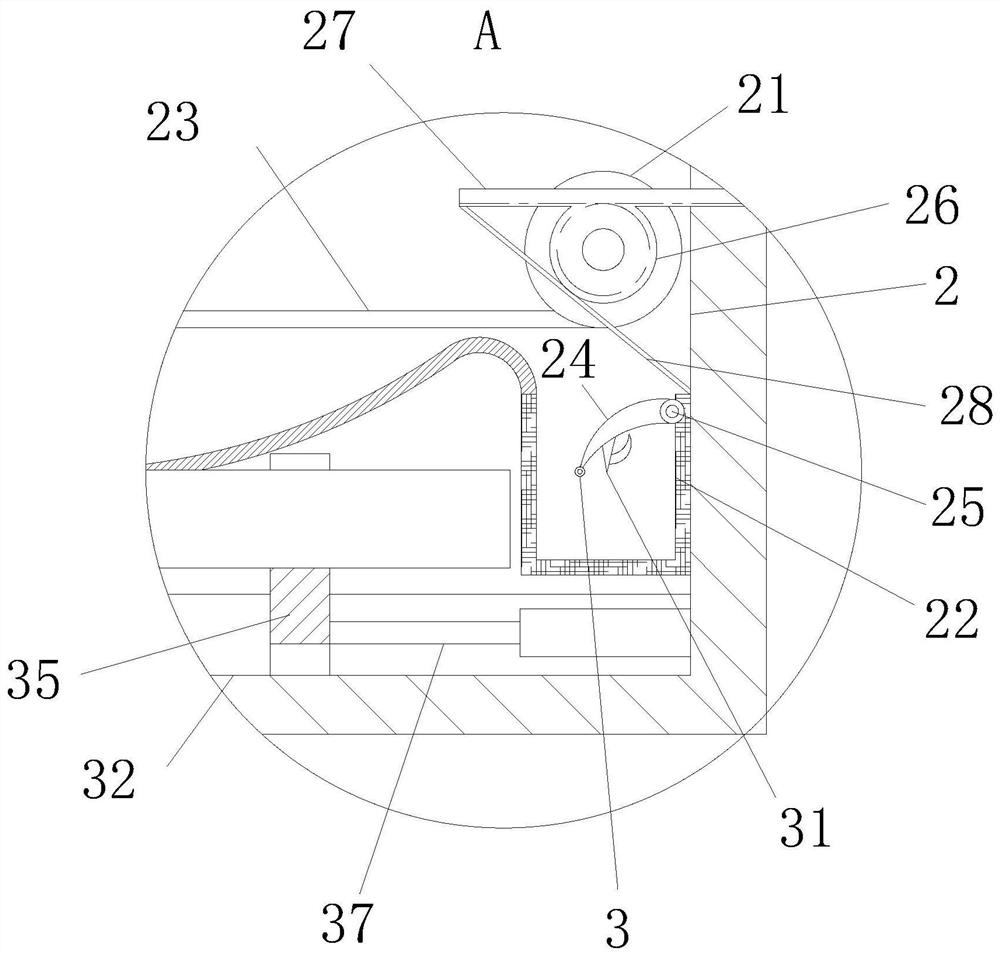

[0029] As an embodiment of the present invention, the side of the recovery bag 22 away from the scraper 19 is connected with a cover plate 24, and the cover plate 24 is hinged to the edge of the recovery bag 22 through a revolving pin 25 and a torsion spring; One side of 21 is fixedly connected with a gear 26, and the top of the gear 26 is provided with a rack 27, and the rack 27 and the gear 26 mesh with each other; the rack 27 runs through the sealing chamber 2 and is in sliding and sealing connection with the sealing chamber 2; the rack 27 One end located in the sealed cavity 2 is fixedly connected with the revolving pin 25 through a pull wire 28; the recovery bag 22 is made of porous filter cloth, and the bottom of the recovery bag 22 communicates with the discharge pipe 16 through a communication hole; through the winding roller 21 When rotating, the gear 26 is driven to rotate, and then the rack 27 is driven to move and tension the backguy 28, so that the backguy 28 drive...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap