Perforating device special for electric power installation parts

A technology for punching devices and mounting parts, which is applied in the directions of positioning devices, feeding devices, maintenance and safety accessories, etc. It can solve the problems of increased labor intensity, large use limitations, and cumbersome use, and achieves wide application range, easy to move, The effect of clamping stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

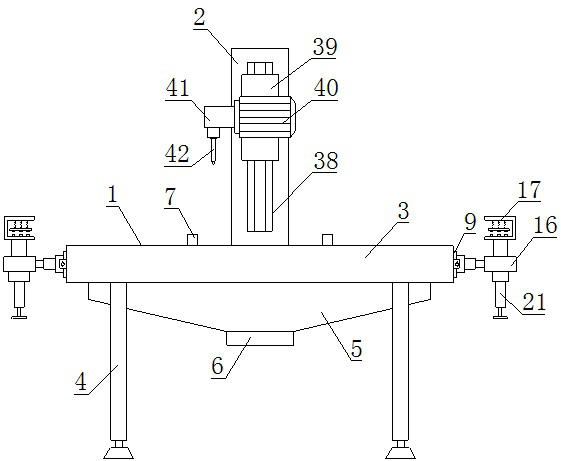

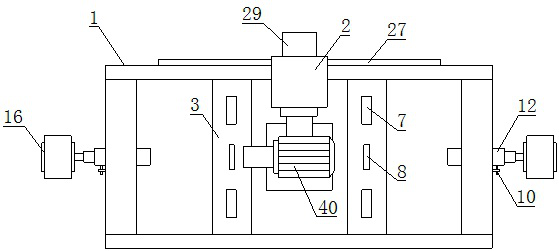

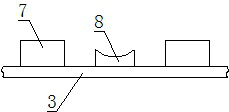

[0029] Such as Figure 1-11 As shown, a special punching device for power installation parts, which includes a placing table 1 and a lifting seat 2, a foot 4 is provided under the placing table 1, and a platen 3 is provided on the upper side of the placing table 1. A support plate 7 is provided on the upper side of the table 3, a support ring 8 is provided on the inner side of the support plate 7, bearing seats 9 are provided on the left and right sides of the placement platform 1, and the front side of the bearing seat 9 is A fixed plate 10 is provided, the inside of the fixed plate 10 is provided with a positioning bolt 11, the middle part of the bearing seat 9 is provided with a rod tube 12, the inside of the rod tube 12 is provided with a telescopic rod 14, and the described telescopic rod 14 is provided with a clip bar 15, the end of the telescopic rod 14 is provided with a support plate 16, and a plate clamp seat 17 is provided above the support plate 16, and a spring 18...

Embodiment 2

[0038] Such as Figure 1-11 As shown, a special punching device for power installation parts, which includes a placing table 1 and a lifting seat 2, a foot 4 is provided under the placing table 1, and a platen 3 is provided on the upper side of the placing table 1. A support plate 7 is provided on the upper side of the table 3, a support ring 8 is provided on the inner side of the support plate 7, bearing seats 9 are provided on the left and right sides of the placement platform 1, and the front side of the bearing seat 9 is A fixed plate 10 is provided, the inside of the fixed plate 10 is provided with a positioning bolt 11, the middle part of the bearing seat 9 is provided with a rod tube 12, the inside of the rod tube 12 is provided with a telescopic rod 14, and the described telescopic rod 14 is provided with a clip bar 15, the end of the telescopic rod 14 is provided with a support plate 16, and a plate clamp seat 17 is provided above the support plate 16, and a spring 18...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com