Intelligent detection machine tool for wood processing

An intelligent detection and wood technology, applied in the direction of wood processing equipment, wood testing, multi-purpose machinery, etc., can solve the problems of anti-cracking performance testing, etc., to achieve the effect of guaranteed quality and easy observation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

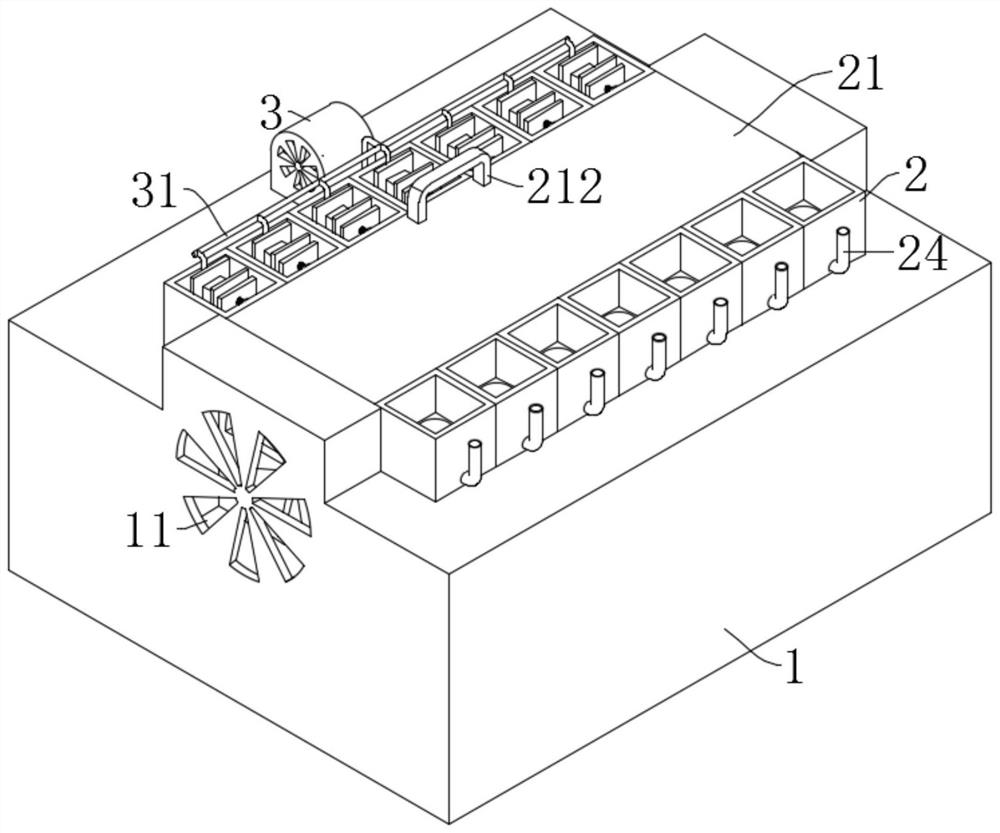

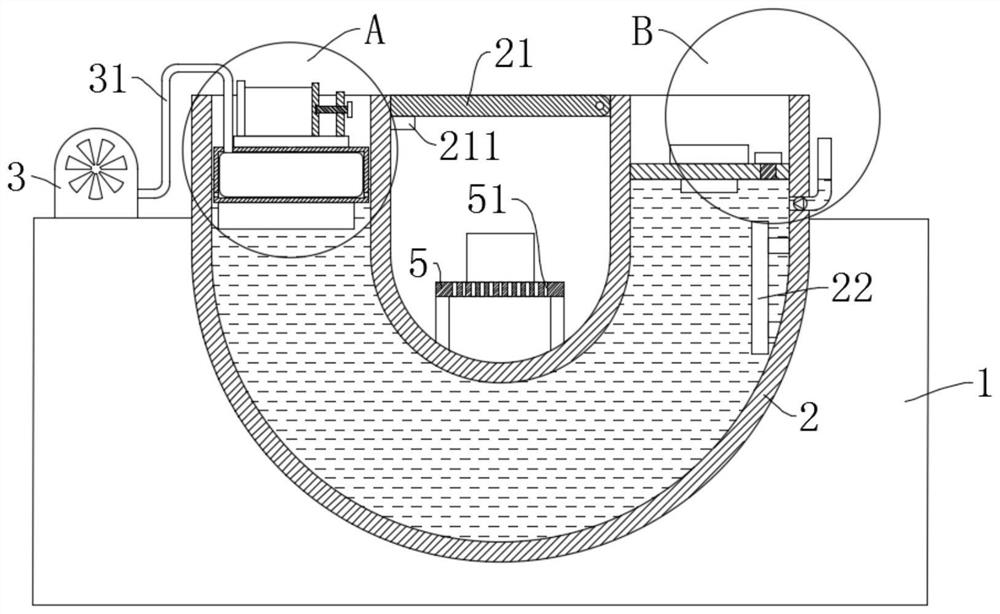

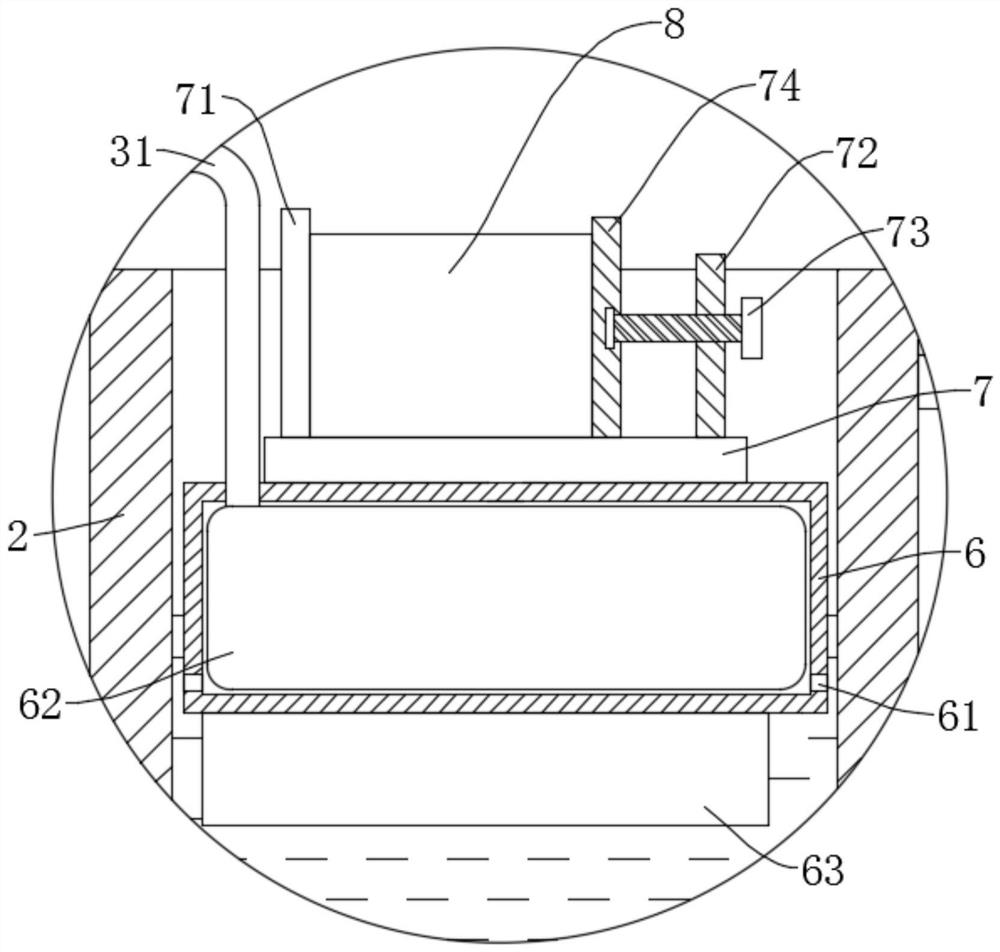

[0031] refer to Figure 1-6 , an intelligent detection machine tool for wood processing, including a workbench 1, and also includes: a plurality of U-shaped tubes 2 inlaid on the workbench 1, wherein the U-shaped tubes 2 are filled with water, and one end of the U-shaped tubes 2 is fixed A sealing plate 23 is connected, and a pressure sensor 231 is fixedly connected to the bottom of the sealing plate 23; the floating box 6 floating on the other end of the U-shaped tube 2, wherein the floating box 6 is provided with an air bag 62, and the floating box 6 is provided with a water hole 61, the bottom of the floating box 6 is fixedly connected with a counterweight 63; the placing plate 7 is fixedly connected to the top of the floating box 6, and the holding plate 7 is provided with a clamping assembly; the air-drying tank is arranged in the recesses of a plurality of U-shaped tubes 2 , both ends of the workbench 1 are provided with fans 11, and the fans 11 correspond to the air-dry...

Embodiment 2

[0033] refer to Figure 1-6 , an intelligent detection machine tool for wood processing, including a workbench 1, and also includes: a plurality of U-shaped tubes 2 inlaid on the workbench 1, wherein the U-shaped tubes 2 are filled with water, and one end of the U-shaped tubes 2 is fixed A sealing plate 23 is connected, and a pressure sensor 231 is fixedly connected to the bottom of the sealing plate 23; the floating box 6 floating on the other end of the U-shaped tube 2, wherein the floating box 6 is provided with an air bag 62, and the floating box 6 is provided with a water hole 61, the bottom of the floating box 6 is fixedly connected with a counterweight 63; the placing plate 7 is fixedly connected to the top of the floating box 6, and the holding plate 7 is provided with a clamping assembly; the air-drying tank is arranged in the recesses of a plurality of U-shaped tubes 2 , both ends of the workbench 1 are provided with fans 11, the fans 11 correspond to the air-drying ...

Embodiment 3

[0035] refer to Figure 1-6 , an intelligent detection machine tool for wood processing, including a workbench 1, and also includes: a plurality of U-shaped tubes 2 inlaid on the workbench 1, wherein the U-shaped tubes 2 are filled with water, and one end of the U-shaped tubes 2 is fixed A sealing plate 23 is connected, and a pressure sensor 231 is fixedly connected to the bottom of the sealing plate 23; the floating box 6 floating on the other end of the U-shaped tube 2, wherein the floating box 6 is provided with an air bag 62, and the floating box 6 is provided with a water hole 61, the bottom of the floating box 6 is fixedly connected with a counterweight 63; the placing plate 7 is fixedly connected to the top of the floating box 6, and the holding plate 7 is provided with a clamping assembly; the air-drying tank is arranged in the recesses of a plurality of U-shaped tubes 2 , both ends of the workbench 1 are provided with fans 11, the fans 11 correspond to the air-drying ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com