Steel pipe bundling device for building material transportation

A technology of bundling device and steel pipe, which is applied in the directions of transportation and packaging, bundling materials, bundling objects, etc., can solve the problems of low safety and low bundling efficiency, and achieve the effects of high safety, convenient operation and convenient removal.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

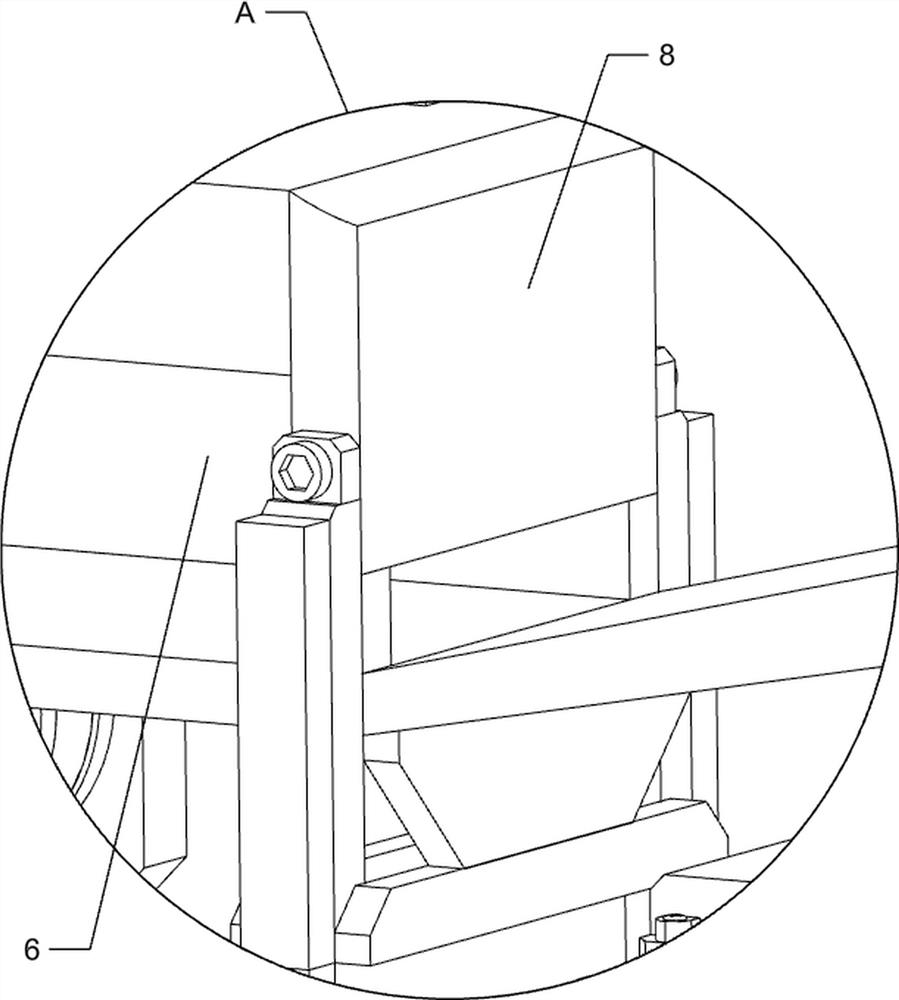

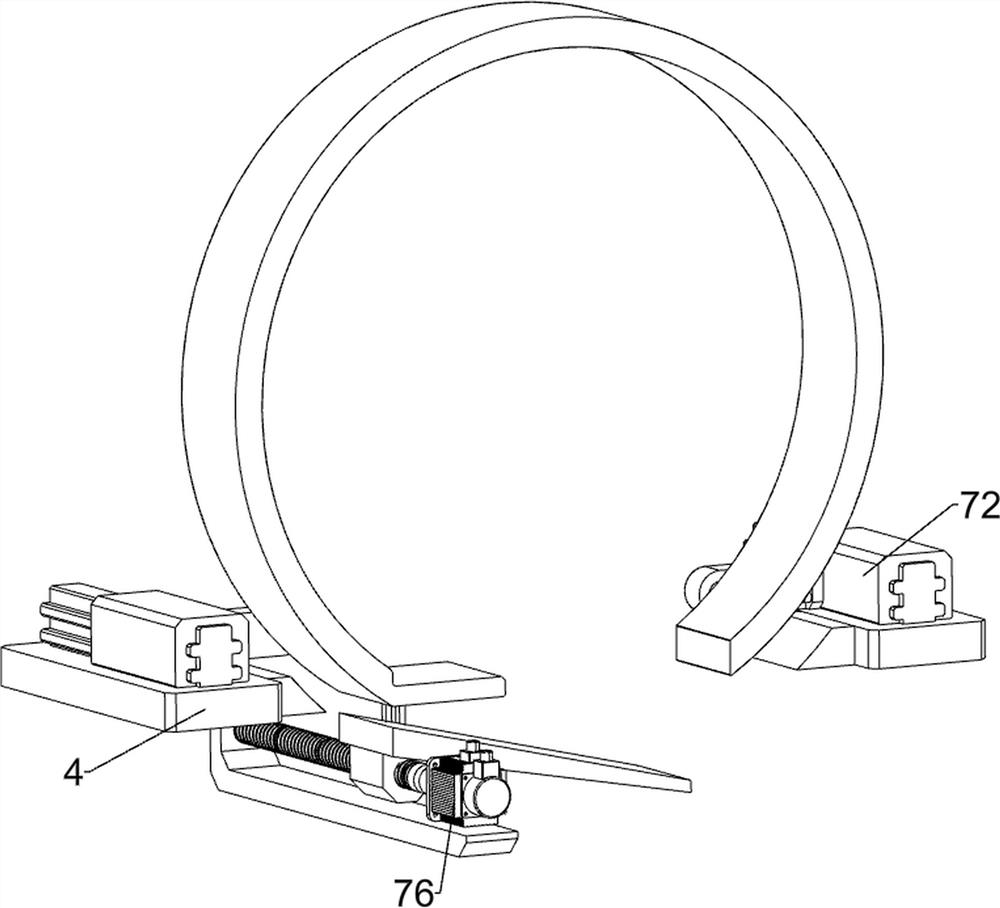

[0079] A steel pipe binding device for building material transportation, such as figure 1 , figure 2 , image 3 , Figure 4 , Figure 5 , Image 6 , Figure 7 , Figure 8 , Figure 9 , Figure 10 and Figure 11 As shown, it includes a base 1, a steel pipe frame 2, a mounting frame 4, a strap 5, a feeding device 6, a movable guide device 7, a tape device 8 and a cutting and welding device 9, and steel pipes are installed on the left and right sides of the top of the base 1 Frame 2, the top right side of the base 1 is slidingly provided with a mounting frame 4, the upper front side of the mounting frame 4 is provided with a feeding device 6, the feeding device 6 is provided with a strap 5, and the upper part of the mounting frame 4 is provided with a movable guide device 7 , The middle part of the mounting frame 4 is provided with a cassette device 8, and the lower part of the mounting frame 4 is provided with a cutting and soldering device 9.

[0080] The feeding dev...

Embodiment 2

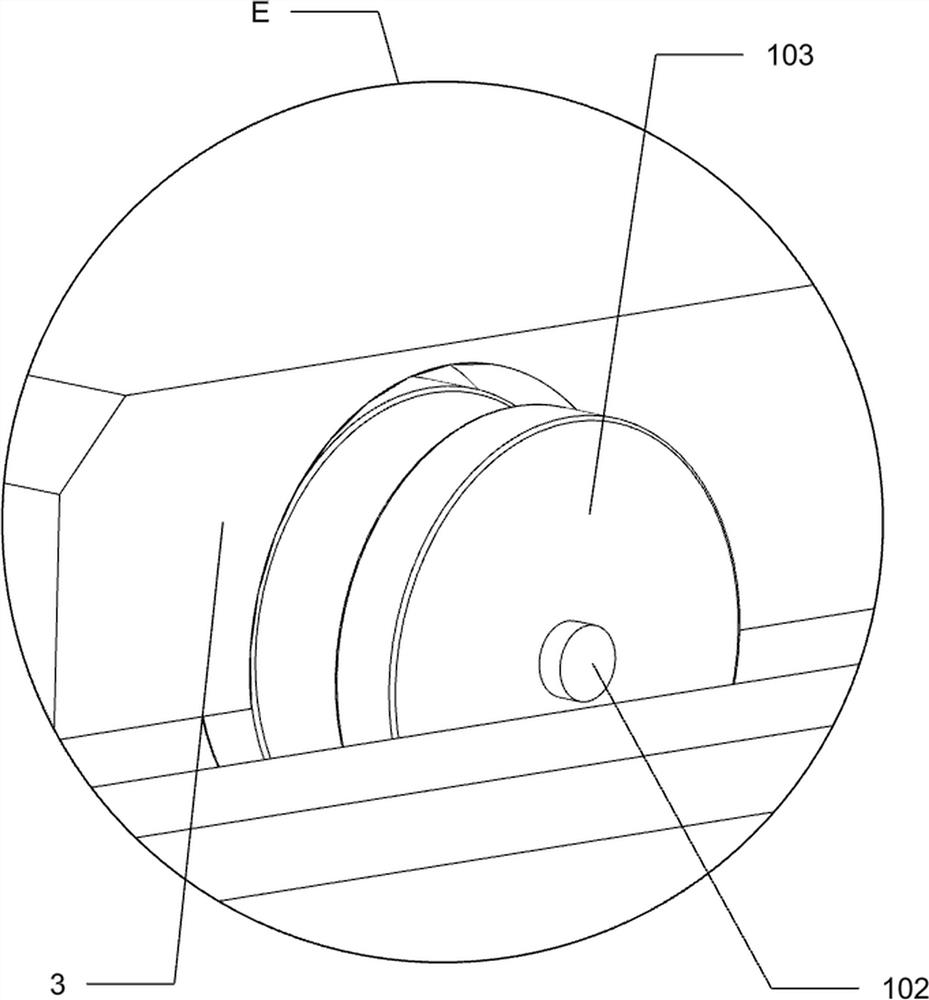

[0086] On the basis of Example 1, such as figure 1 , Figure 12 , Figure 13 , Figure 14 and Figure 15 As shown, also includes sliding device 10, and sliding device 10 includes second slide rail 101, fourth rotating shaft 102 and pulley 103, and base 1 top, front and rear sides are all provided with second slide rail 101, and mounting frame 4 bottom left and right sides The side-rotating type is provided with a fourth rotating shaft 102, and pulleys 103 are arranged on the front and rear sides of the fourth rotating shaft 102, and the pulleys 103 all roll on the second slide rail 101 on the same side.

[0087] When people need to bind both sides of the steel pipe, they can move the installation frame 4 left and right. Under the action of the pulley 103, all parts on the installation frame 4 are driven to move left and right, so that people can bind both sides of the steel pipe conveniently.

[0088] Also comprise auxiliary load-bearing device 11, auxiliary load-bearing d...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com