Friction-driven material pushing robot

A pusher robot, friction-driven technology, applied in the direction of conveyor objects, animal feeding devices, loading/unloading, etc., can solve the problems of insufficient pusher capacity, large front resistance, and inadequate push, etc., to improve cleaning and push Effects, Improving Push Ability, Reducing Missed Effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

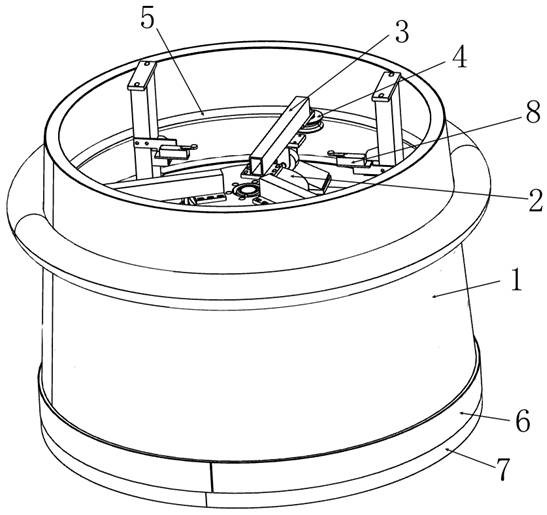

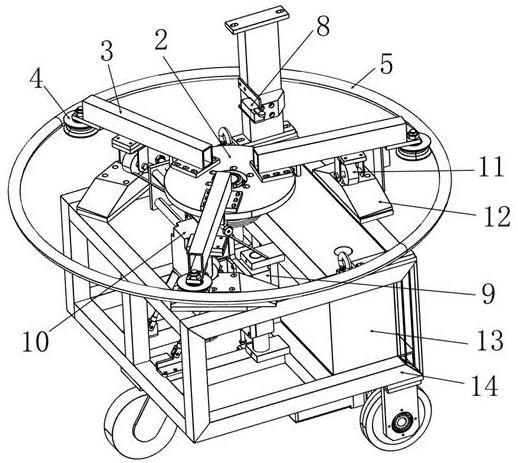

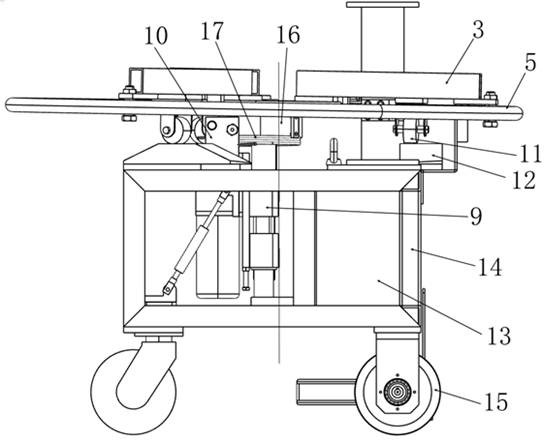

[0032] In a typical embodiment of the present invention, such as Figure 1-Figure 4 As shown, a friction-driven pushing robot is proposed.

[0033] Aiming at the problem that the current pusher robot is difficult to effectively push and stack loose and light feed, a friction-driven pusher robot is provided. The friction-driven rotating shell 1 is set to push and accumulate the feed. Surface to obtain friction to drive the rotating shell 1 to rotate, reduce the impact of feed contact cylinder friction on pushing efficiency, solve the problem of poor pushing efficiency of traditional pushing robots, and improve the ability to push scattered feed.

[0034] For the friction-driven pusher robot, it mainly includes a self-propelled platform, a rotating shell 1, a guide plate 2 and a lifting mechanism. The self-propelled platform is used as a whole mobile load-bearing structure, which drives the components installed on it to move as a whole, along the extension direction of the fence...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com