A large diameter and large pitch screw surface induction heating device and surface heating method

A heating device and surface induction technology, which is applied in the direction of quenching device, heat treatment furnace, heat treatment equipment, etc., can solve the problems of inaccessibility, large temperature difference in the direction of the tooth profile, cracks on the workpiece surface, etc., and achieve the effect of improving the heating quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

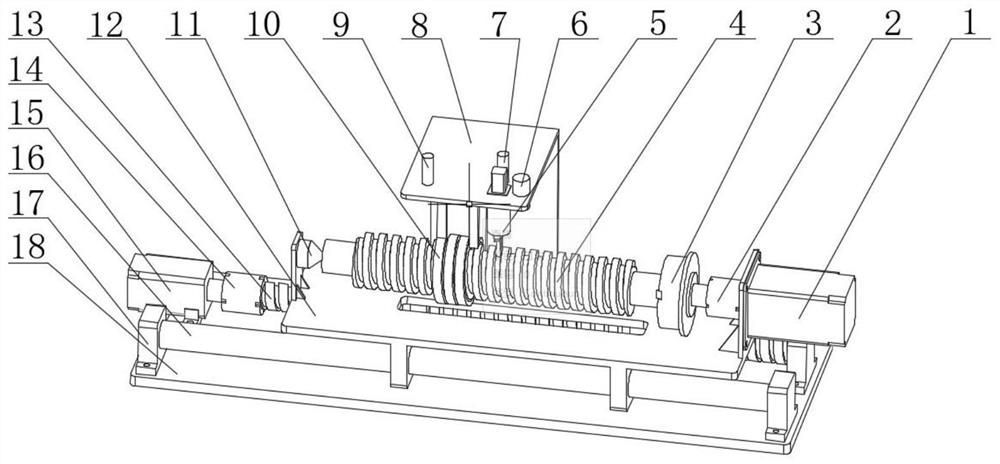

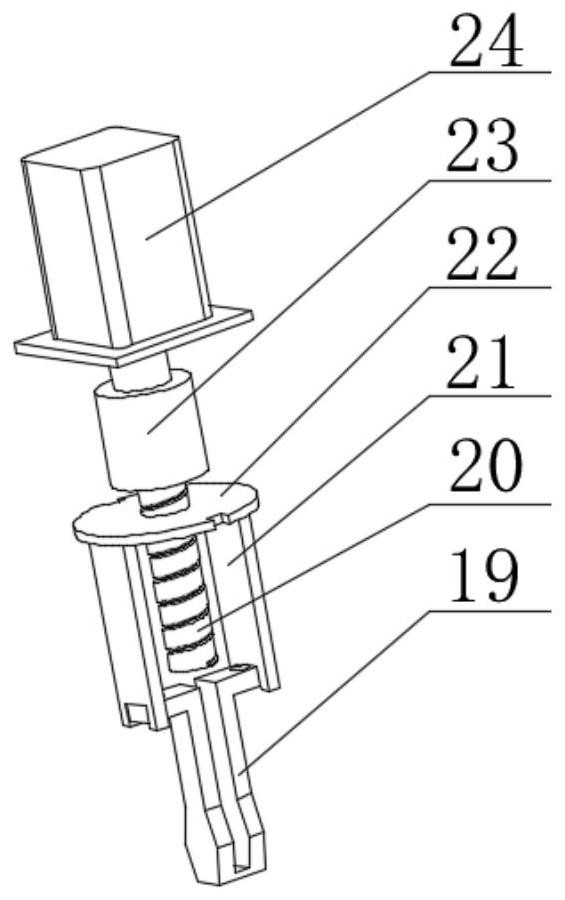

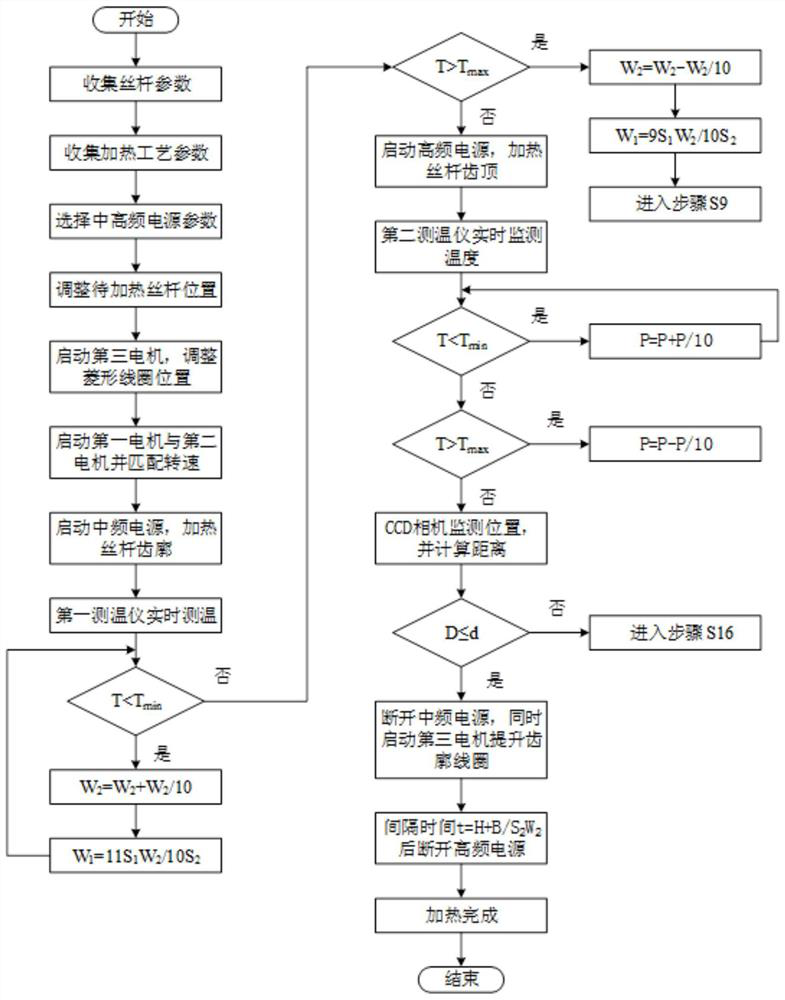

[0064] exist figure 1 , figure 2 and image 3 Among them, a large-diameter and large-pitch screw surface induction heating device includes a telescopic induction coil device 5 for heating the surface of the screw tooth profile, a base transmission device, a mobile sliding table device, a thermometer, a CCD camera 6 and a spiral Coil 10.

[0065] The mobile sliding table device includes a sliding table 12, a second motor 1, a second coupling 2, a three-grip chuck 3, a screw rod to be heated 4 and a top 11, one end of the screw rod 4 to be heated ( figure 1 The middle right end) is clamped by the three gripping chuck 3, and the other end ( figure 1 The middle left end) is connected with the top 11 (top tight connection), the three-grip chuck 3 is connected with the second motor 1 through the second coupling 2, and the second motor 1 and the top 11 are respectively fixed on the support on the left and right sides of the slide table 12 On the board, the sliding table 12 is in...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com