Multi-layer knitted vamp

A shoe upper and knitting technology, applied in knitting, weft knitting, warp knitting, etc., can solve the problems of thin upper, unable to meet the requirements, and unable to keep warm, and achieve diversified functions, beautiful and rich patterns, Improve the effect of visual effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach 1

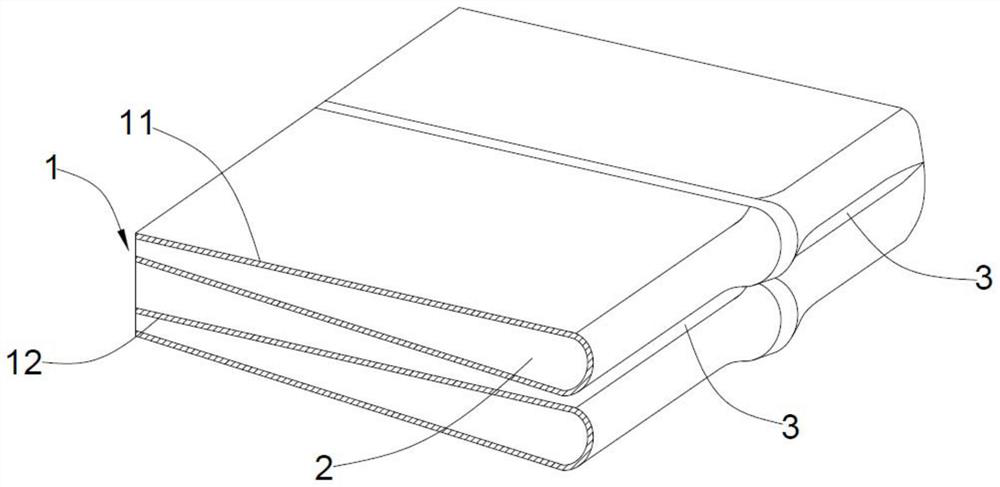

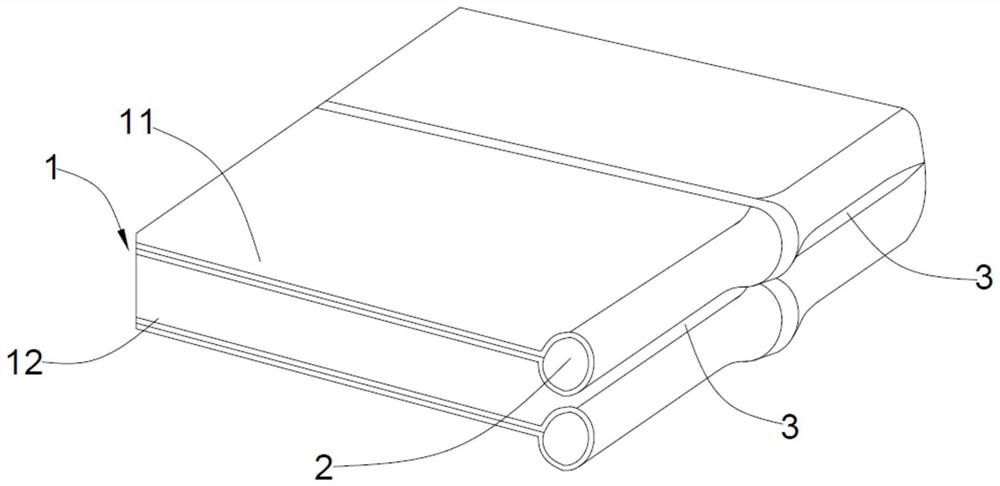

[0030] In this embodiment, the shoe upper body includes two braided layer groups 1, the two braided layer groups 1 are integrally braided and formed, and the first filling layer 2 is formed between the two braided layer groups 11, and the two braided layer groups 1 to form a second filling layer 3.

Embodiment 1

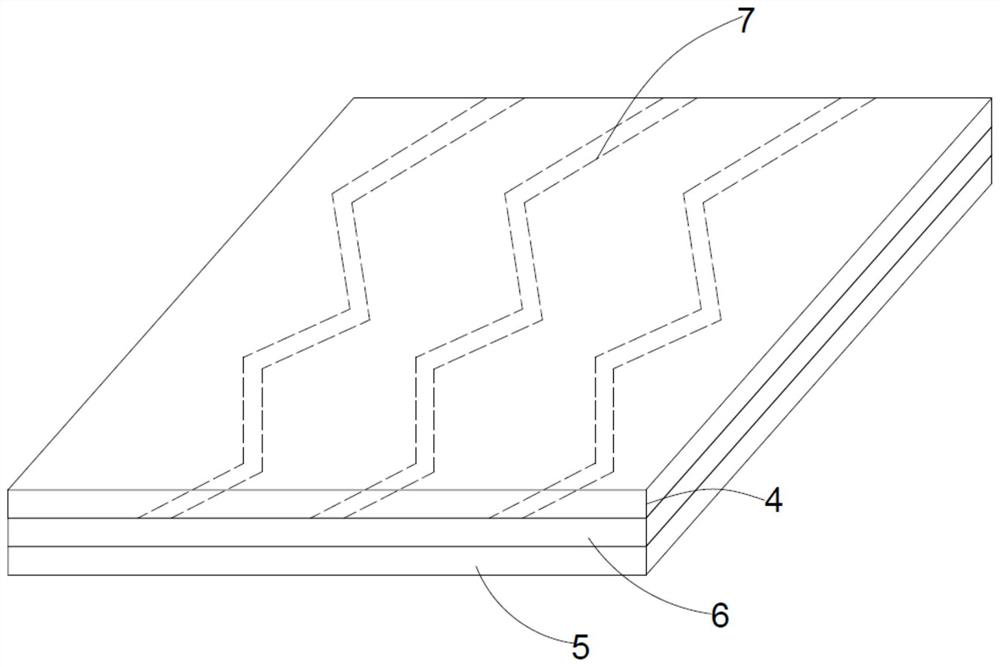

[0032] refer to Figure 4 , A and B yarns, both of which are polyester high-elastic double-wrapped yarns, are selected for weaving. The first weaving line is A yarn for "knitting two empty needles and one needle every other" to form the surface layer; The 2nd knitting row is to do the bottom knitting of "knitting two bottom needles every two needles" with B yarn to form the bottom layer; the 3rd knitting row is to move the rear needle bed coil made of B yarn to the left by one needle position and then Transfer knitting to the front needle bed is used to free up the rear needle bed and avoid the knitting action of the rear needle bed. Finally, it is used to form a knitting layer 11 of the upper knitting layer group 1. The fourth knitting row is made of A yarn "knit one face needle every two empty needles" for surface knitting, which is used to form the surface layer, and the fifth knitting row is B yarn to do bottom knitting for "knit two bottom needles every two empty needles"...

Embodiment 2

[0034] The difference between this embodiment and Embodiment 1 is that the first filling layer 2 formed by weaving is cylindrical and is located at the junction of the two braiding layers 11, and the cylindrical first filling layer 2 can be filled with strip-shaped filling accordingly. Specifically, the first filling layer 2 can be filled with fillers such as elastic bands to decorate the edge of the knitted shoe upper.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com