High-color-fastness antibacterial wear-resistant home textile fabric preparation device and process

A technology with high color fastness and preparation equipment, which is applied in textile processing machine accessories, textile material processing drums, liquid/gas/steam textile material processing, etc., can solve problems such as poor practicability, improve dehydration effect, save Usage amount, effect of pollution prevention

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

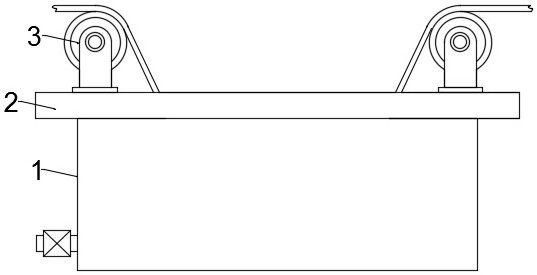

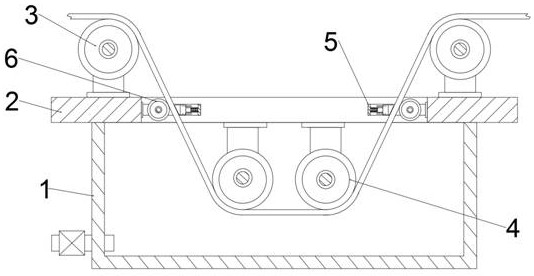

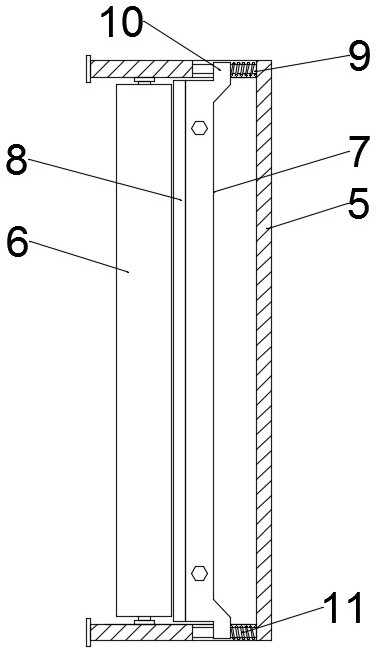

[0024] Example: see Figure 1-4 , a high color fastness antibacterial and wear-resistant home textile fabric preparation device and process in the present invention, comprising a dipping box 1, a mounting plate 2 arranged at the top opening of the dipping box 1, and a mounting plate 2 arranged on both sides of the top surface of the mounting plate 2 The upper roller 3, the middle part of the top surface of the installation plate 2 is provided with a discharge opening, and the two sides of the middle part of the bottom surface of the installation plate 2 are longitudinally provided with the lower idler roller 4; the inner walls of both sides of the discharge opening are horizontally installed with installation frame plates 5. The installation frame plate 5 is equipped with a wiper assembly for dehydration of home textile fabrics; through the guide roller 6 and the dehydration scraper 8 in the wiper assembly, it is convenient to scrape out the excess dyeing solution from the fabr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com