Construction method for cast-in-place of single-column pier capping beam

A construction method and single-column pier technology, applied in the direction of bridges, bridge parts, bridge construction, etc., can solve the problems of difficult control of hoop processing accuracy, long time-consuming design, processing and installation, and insufficient friction resistance of single-column pier, etc., to achieve Easy and fast installation and disassembly, saving manpower and saving materials

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

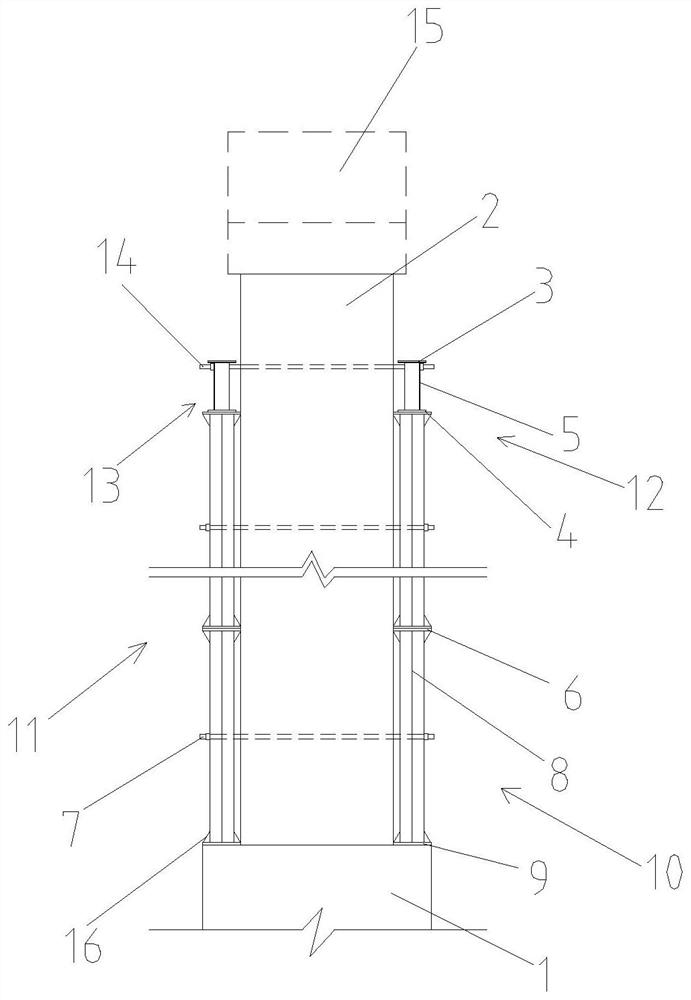

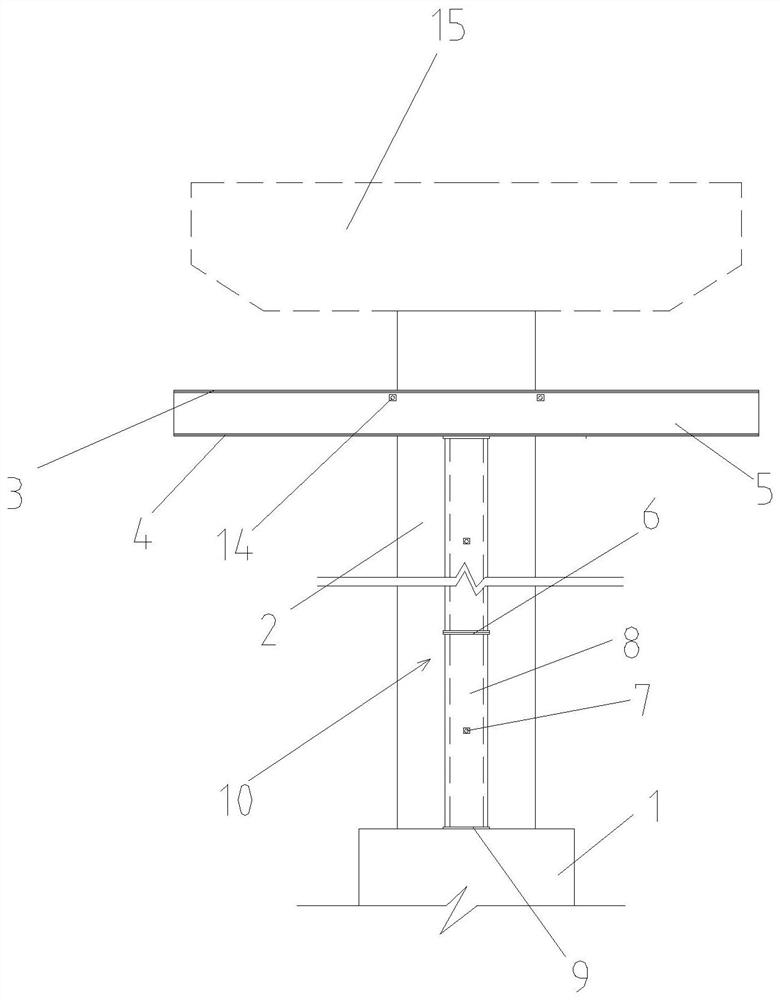

[0054] Such as Figure 1 to Figure 4 Shown is a single-column pier cap beam cast-in-situ construction method, which method includes the following steps:

[0055] Step 1. Pre-embed the PVC pipe in the single column pier:

[0056] During the pouring construction process of the single column pier 2, a plurality of PVC pipes are pre-embedded in the single column pier 2 along the height direction of the single column pier 2; The length direction of the cover beam 15 is arranged vertically;

[0057] Step 2. Fabrication of supporting steel columns:

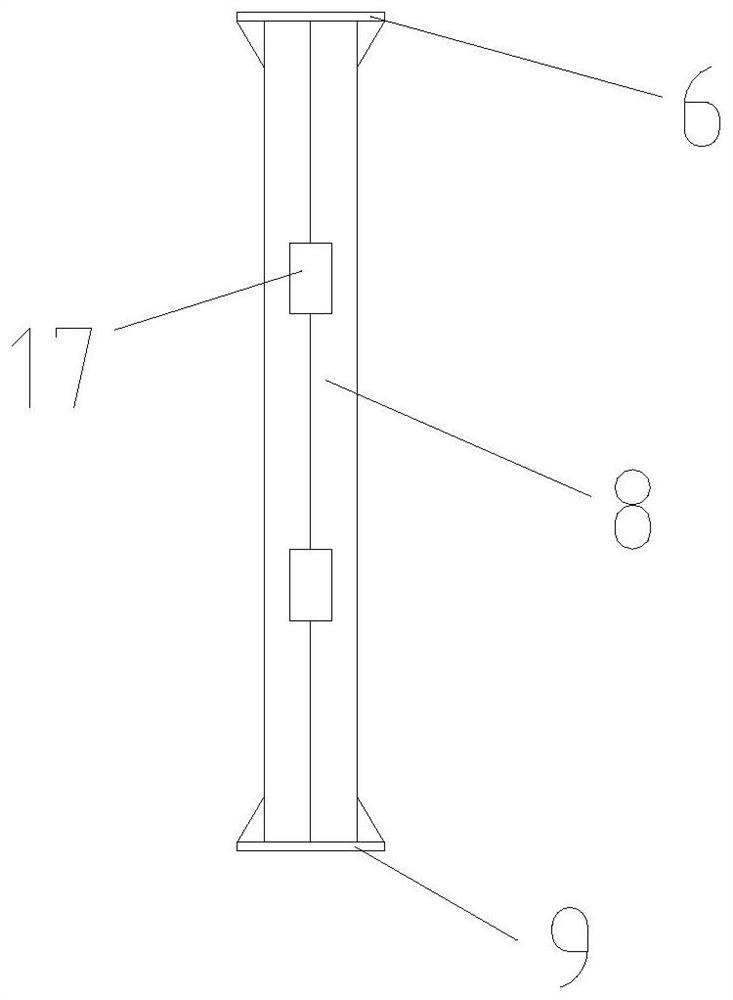

[0058] Step 201, weld two channel steel butt joints to obtain a channel steel column 8, and weld a bottom backing plate 9 at the bottom of the channel steel column 8, and weld a top plate 6 at the top of the channel steel column 8 to obtain a supporting steel column section ;

[0059] Step 202, multiple times according to the method described in step 201, to obtain a plurality of supporting steel column segments;

[0060] Step 3, ho...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com