Secant pile guide wall formwork and formwork supporting structure construction method

A technology of occlusal piles and templates, which is applied in the direction of foundation structure engineering, sheet pile walls, buildings, etc., and can solve problems affecting the construction period, quality and construction progress, affecting the construction of occlusal pile pile machines, the position and size deviation of guide walls, etc. , to achieve the effect of improving construction economic benefits, improving construction flexibility, and reducing construction noise

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0039] The technical solutions in the embodiments of the present invention will be described below in the following description. Embodiments in the present invention, those of ordinary skill in the art are in the range of protection of the present invention without making creative labor.

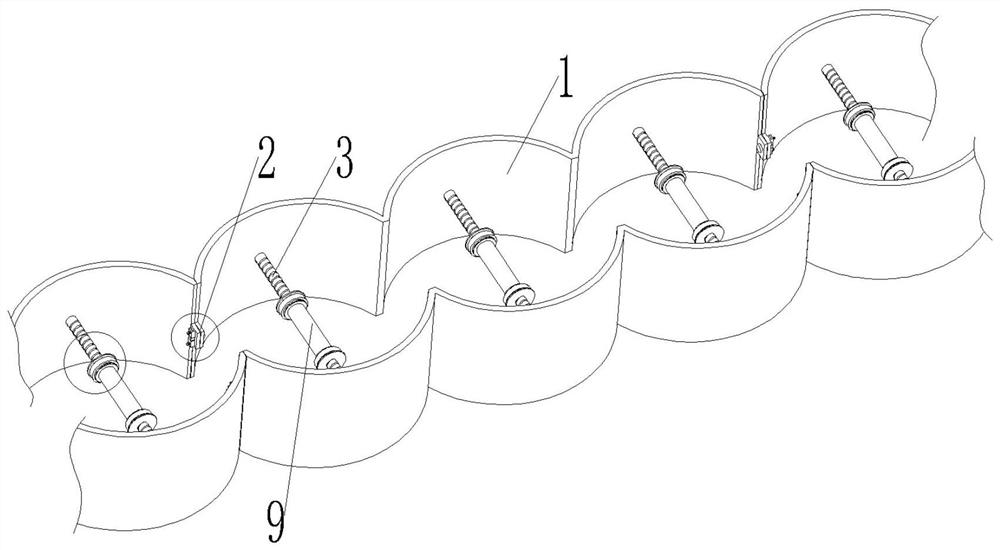

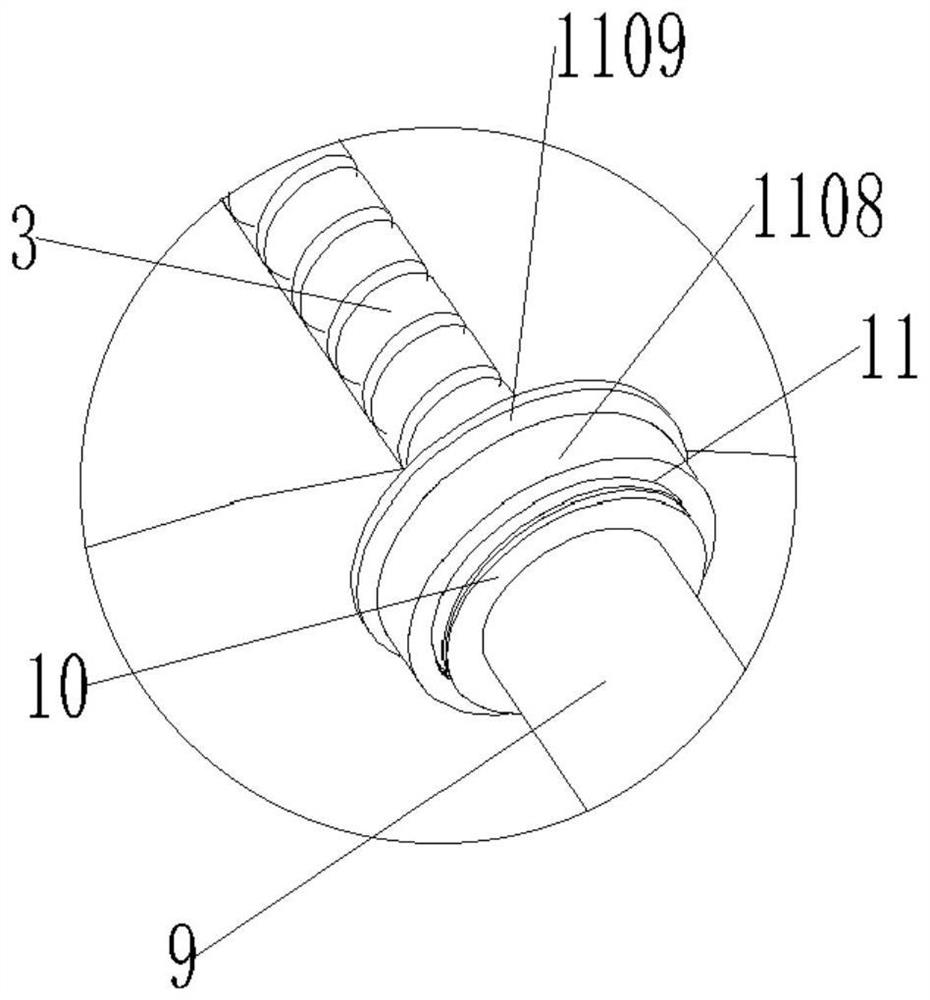

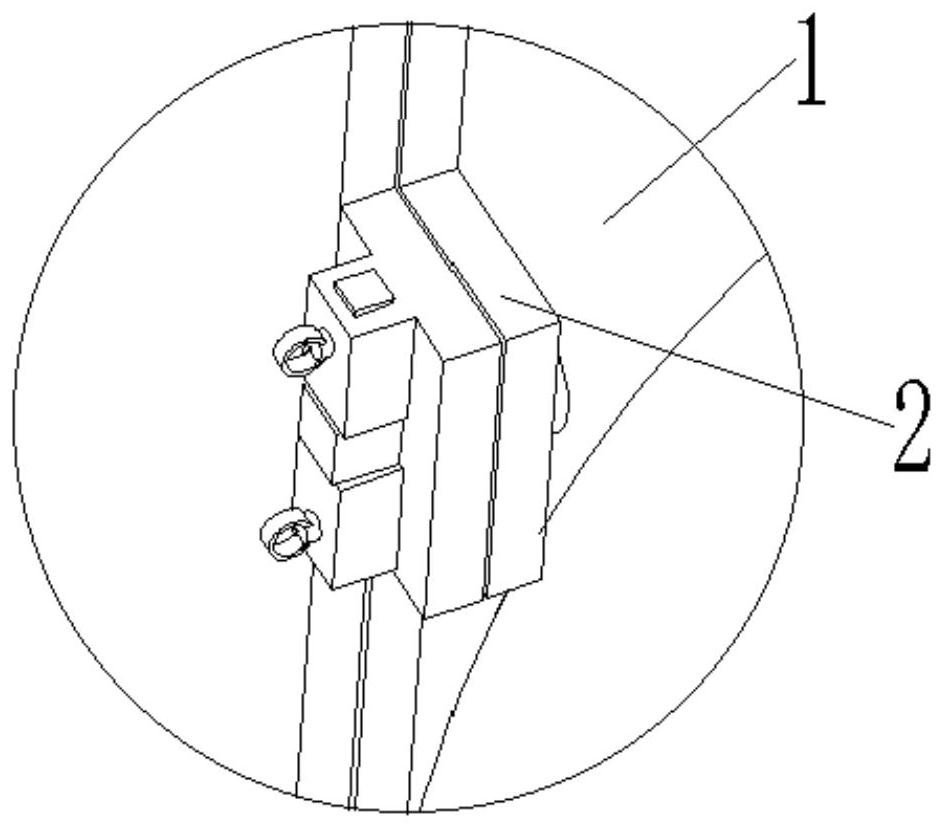

[0040] See Figures 1 to 11 The present invention provides a technical solution: a bite pile guide template, the present invention includes a template unit body 1, a connecting plate 2, a connection screw 3, and a first locking assembly 8, an inner threaded sleeve 9, a second lock assembly 11;

[0041]The two ends of the template unit body 1 are symmetrically configured with a connecting plate 2, and the connecting plate 2 is connected to a square through hole 4, and the inner side wall of the template unit body 1 is fixedly provided with a connection screw 3;

[0042] The square through hole 4 is inserted and provided having a connecting rod portion 5, and one end of the connecting rod member 5 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com