Circuit board electrical testing machine expansion automatic dotting device

A technology of circuit boards and electric testing machines, which is applied in the field of extended automatic dotting devices for circuit board electric testing machines, which can solve problems such as single dot speed, low degree of automation, and inaccurate dots, so as to avoid missing dots and improve dot accuracy. , Improve the efficiency of management

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

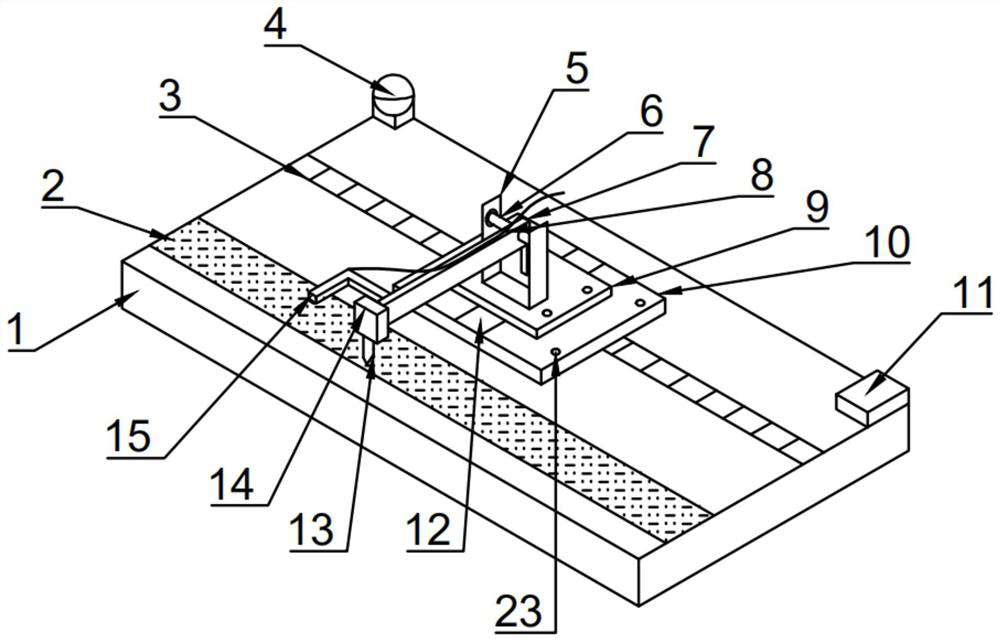

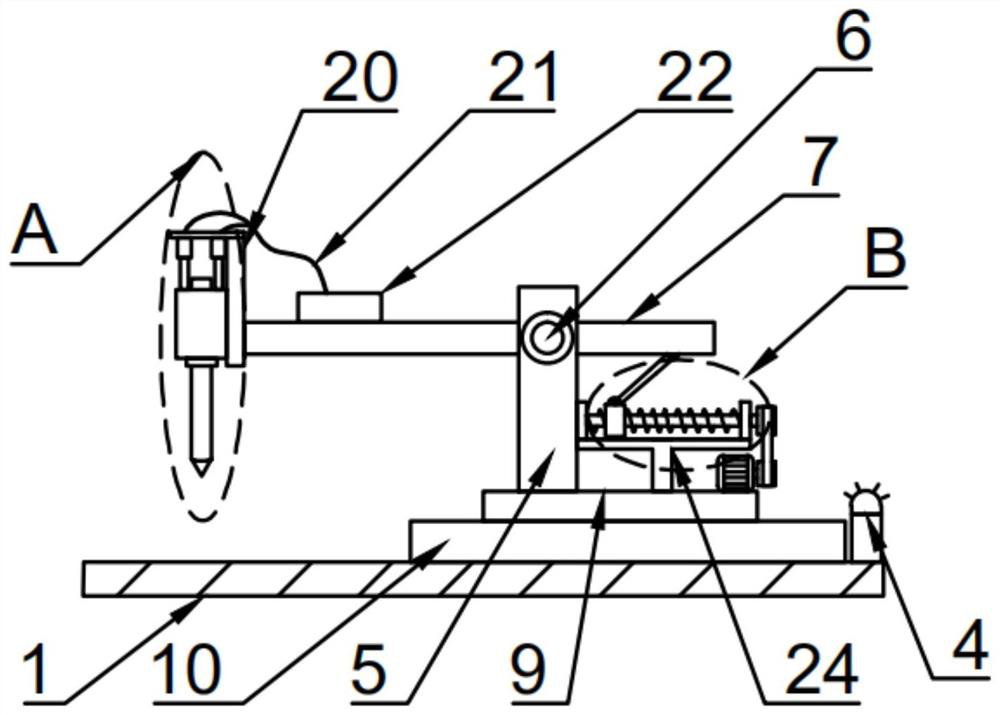

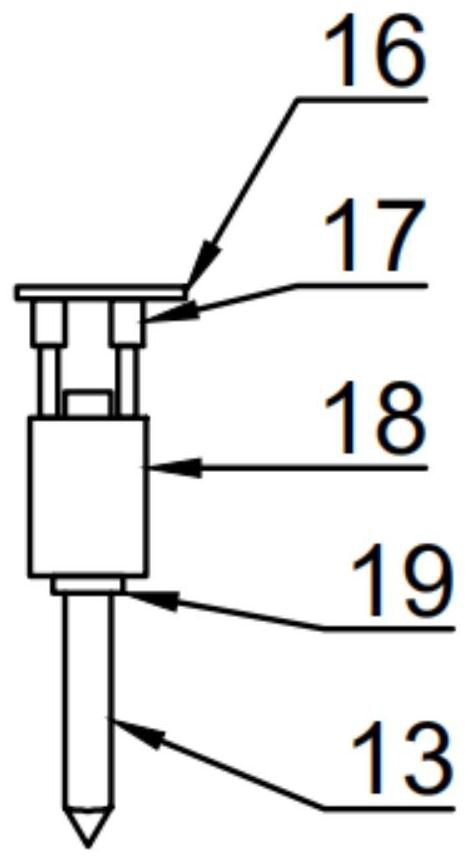

[0025] see Figure 1~4 , in the embodiment of the present invention, a circuit board electrical testing machine extended automatic marking device, including a workbench 1, the workbench 1 is provided with a conveyor belt 2 for transporting circuit boards, and the workbench 1 is also provided with a fixed Assemblies, the U-shaped bracket 5 for supporting the connecting rod 7 is installed and fixed on the fixed assembly, the middle of the U-shaped bracket 5 is installed and fixed with a rotating tube 6, and the connecting rod 7 is rotatably installed at the middle position of the rotating tube 6 , the left end of the connecting rod 7 is installed and fixed with a mounting assembly 14, the mounting assembly 14 includes a first fixing plate 16, a second fixing plate 20, a pneumatic push rod 17 and a sleeve 18, the second fixing Plate 20 is installed on the end of connecting rod 7, and the top of second fixed plate 20 is equipped with first fixed plate 16, and the bottom of describ...

Embodiment 2

[0028] see Figure 1~4 , the difference between this embodiment and embodiment 1 is:

[0029] In this embodiment, the fixed assembly includes a mobile platform 10 and a base 9, the worktable 1 is provided with a first guide rail 3, the mobile platform 10 is slidably mounted on the first guide rail 3, and the mobile platform 10 There is also a second guide rail 12 on the top, the base 9 is slidably installed on the mobile platform 10 through the second guide rail 12, and the U-shaped bracket 5 is installed and fixed on the base 9, through the connection between the first guide rail 3 and the second guide rail 12 The design can realize the reciprocating movement of the mobile platform 10 on the workbench 1 along the direction of the first guide rail 3 and the reciprocating movement of the base 9 on the mobile platform 10 along the direction of the second guide rail 12, which is convenient for adjusting the working position of the dotting pen 13 , improve the use flexibility of ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com