Battery module and busbar welding method thereof

A battery module and welding method technology, which is applied to battery pack components, welding equipment, laser welding equipment, etc., can solve the problems of high busbar cost, high height and size, and large busbar volume, so as to reduce reserved Effects of space, mass reduction, volume reduction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0036] Specific embodiments of the present disclosure will be described in detail below in conjunction with the accompanying drawings. It should be understood that the specific embodiments described here are only used to illustrate and explain the present disclosure, and are not intended to limit the present disclosure.

[0037] In this disclosure, the use of orientation words such as "up, down, left, right" generally means "above", "below", " "Left side", "right side"; "inner and outer" refer to the "inner side" and "outer side" of the specific parts referred to in the drawings; "far and near" refer to the specific parts referred to in the drawings distance.

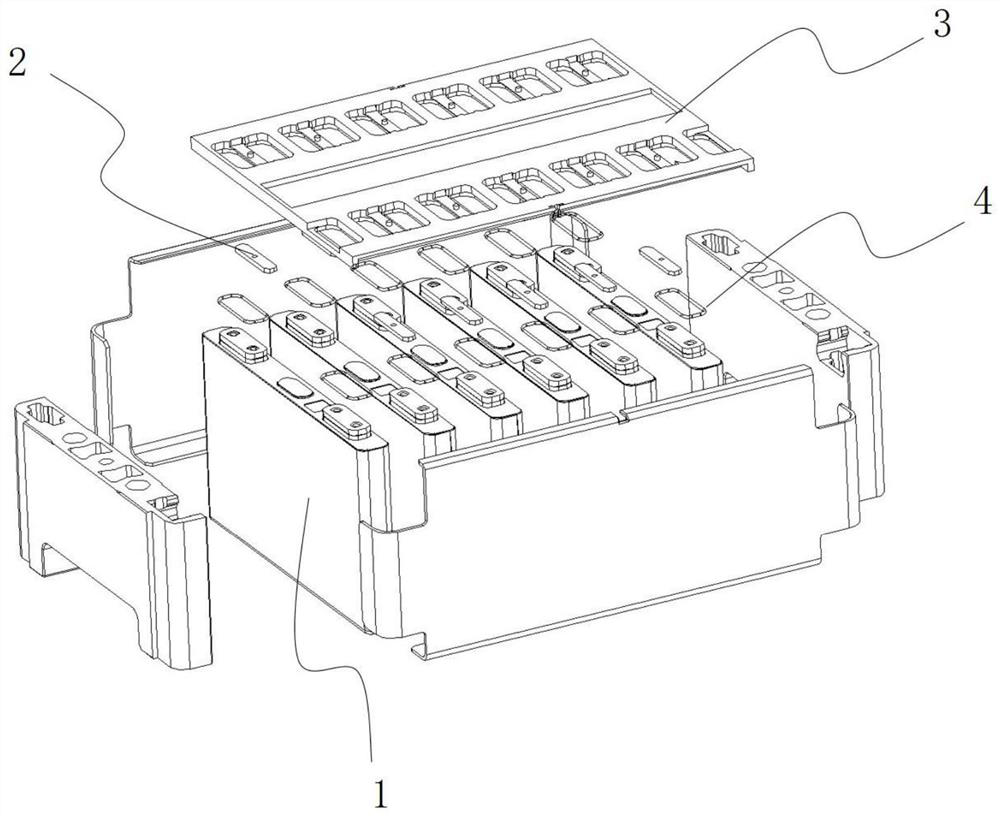

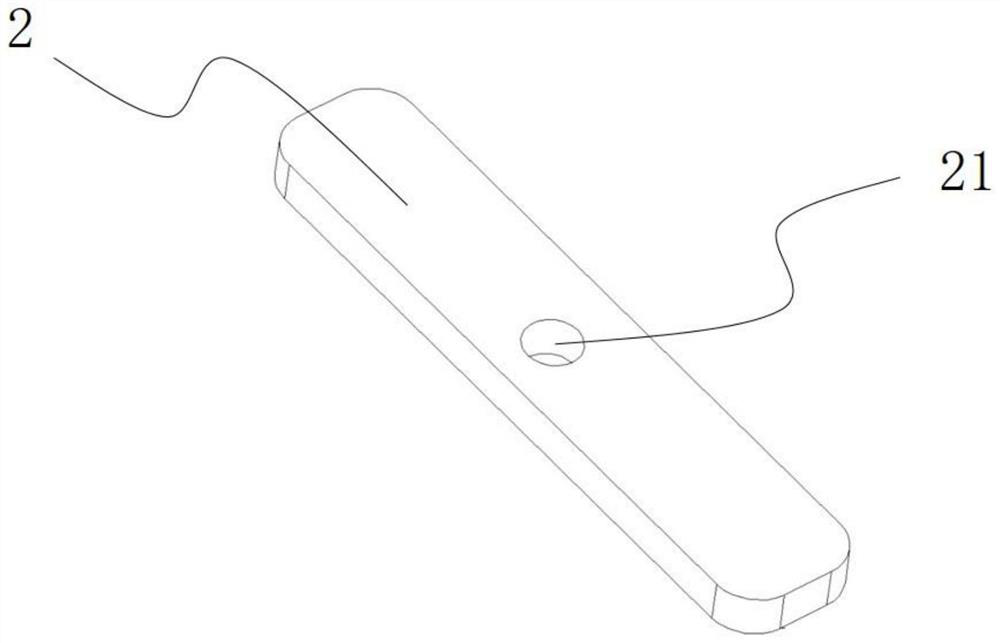

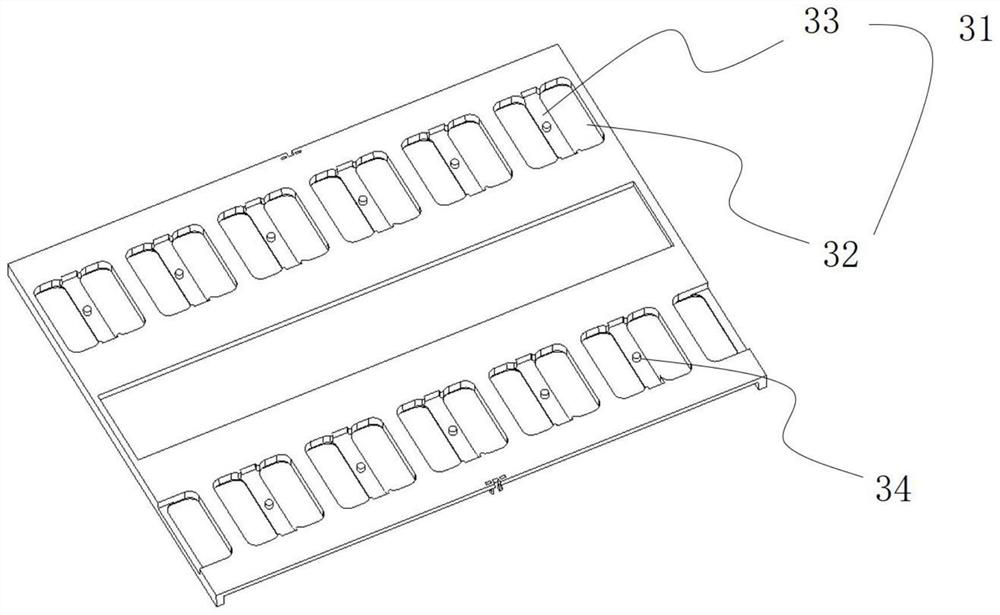

[0038] Such as Figure 1~5 As shown, the present disclosure firstly provides a battery module, including: a battery cell 1, which supplies power to the battery module, and a plurality of battery cells 1 are arranged along the thickness direction to form a battery cell group, and the battery cell group is the entire ba...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com