Asymmetric PES filter membrane for removing viruses, and preparation method thereof

An asymmetric and membrane-filtering technology, applied in the field of membrane materials, can solve the problems of restricting the development of virus-removing membranes, cumbersome configuration of casting membrane liquid, complex composite process, etc., and achieves a technology suitable for large-scale promotion, high throughput, and simple preparation process Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

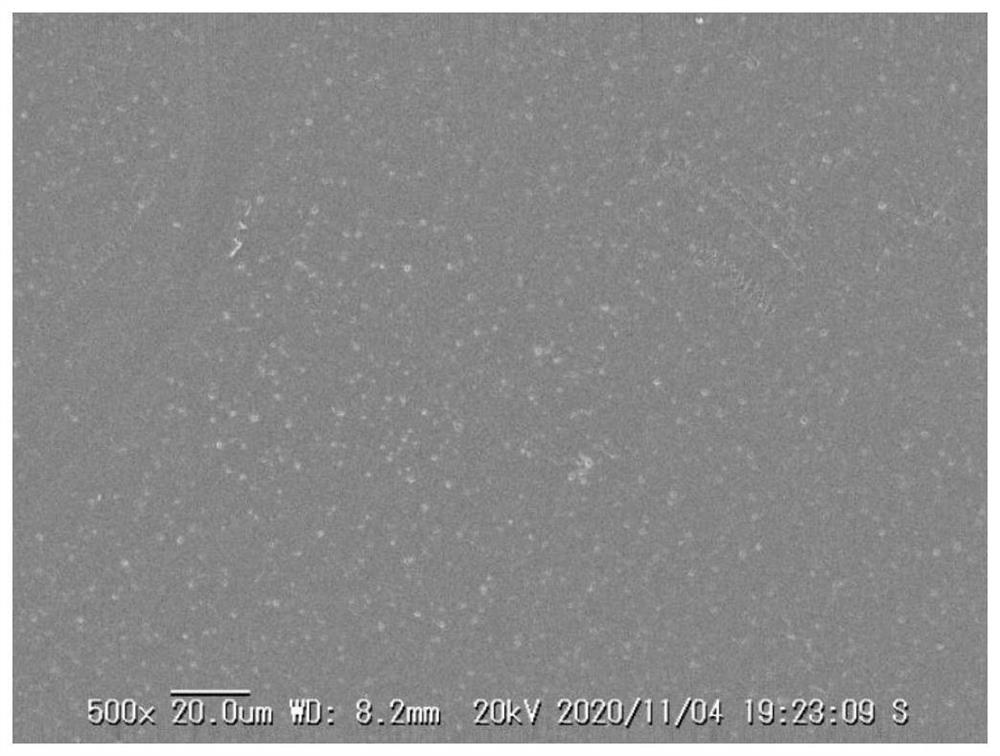

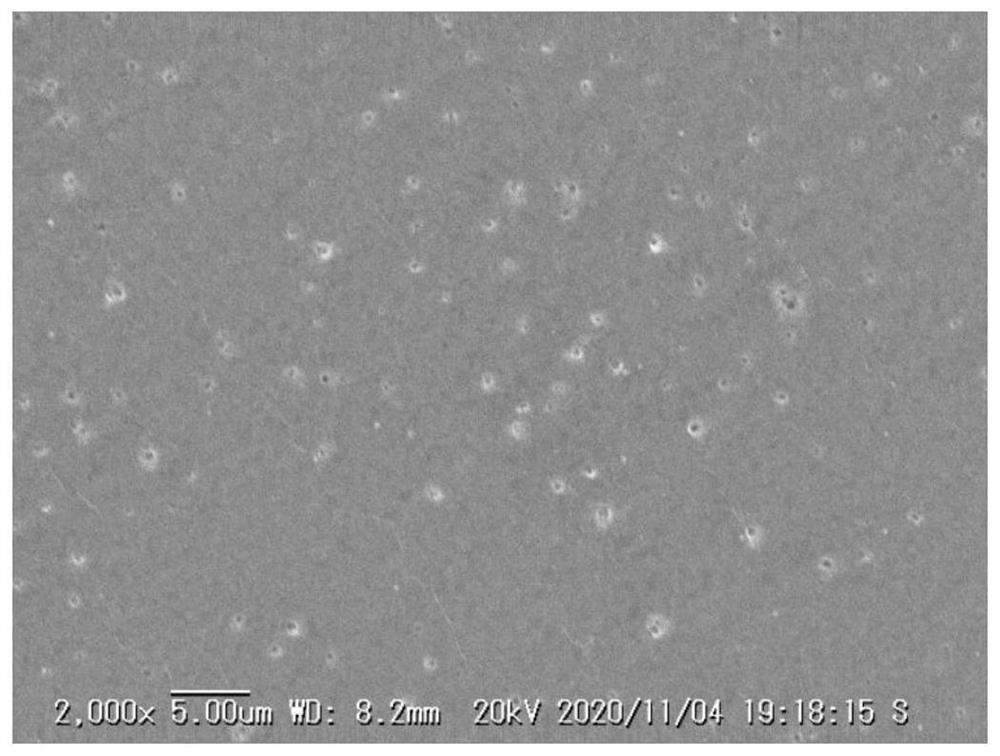

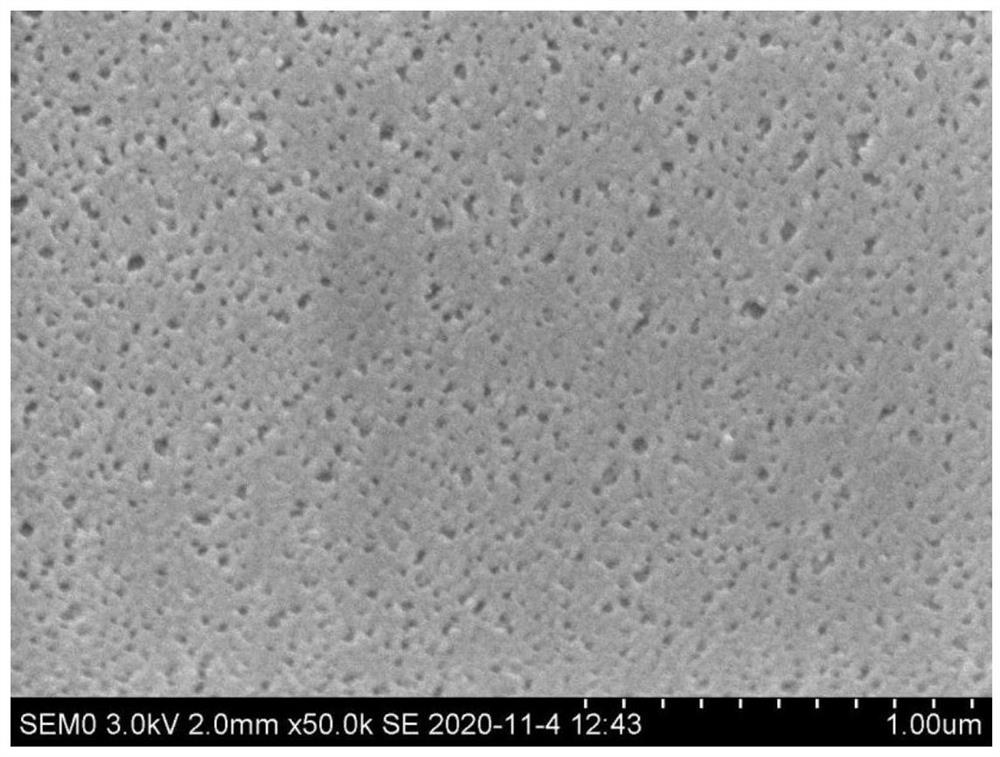

Image

Examples

Embodiment 1

[0080] A method for preparing an asymmetric PES membrane with a virus other, comprising the steps of:

[0081] S1: Preparation of a casting solution, a liquid film is formed and cast onto a support; wherein said casting solution comprising by weight parts consisting of the following: 20 parts of polyether sulfone; organic solvent 75 parts; 20 parts of a polar additive; the said casting solution viscosity of 7500 cps; organic solvent is dimethylformamide; polar additive is glycerol, a mixture of polyvinyl alcohol and the amide N-2- propan-hydroxybutyl azobis methyl, mass ratio of 2 : 1: 1;

[0082] S2: The film was immersed together with the support for 40 seconds and solidifying liquid, a liquid phase diffusion within the cured film inner and invasive, and further cured to form a separation layer and a prefiltration layer; curable liquid comprises water and the osmotic additives isopropyl alcohol, the additive content of the permeate is 50%; wherein the curing solution temperature...

Embodiment 2

[0084] A method for preparing an asymmetric PES membrane with a virus other, comprising the steps of:

[0085] S1: Preparation of a casting solution, a liquid film is formed and cast onto a support; wherein a casting solution comprising by weight parts consisting of the following: 21 parts of polyether sulfone; organic solvent 70 parts; 18 parts of a polar additive; casting solution the viscosity of 8000cps; organic solvent is N- ethylpyrrolidone; polar additive is glycerol, a mixture of polyvinyl alcohol and the amide N-2- propan-hydroxybutyl azobis methyl, mass ratio of 2: 1: 1 ;

[0086] S2: The film was immersed together with the support for 45 seconds and solidifying liquid, a liquid phase diffusion within the cured film inner and invasive, and further cured to form a separation layer and a prefiltration layer; solidifying liquid comprising water and ethanol penetration additives, permeation additives content 55%; the curing solution temperature at 30 ℃, the support temperatu...

Embodiment 3

[0088] A method for preparing an asymmetric PES membrane with a virus other, comprising the steps of:

[0089] S1: Preparation of a casting solution, a liquid film is formed and cast onto a support; wherein said casting solution comprising by weight parts consisting of the following: 23 parts of polyether sulfone; organic solvent 65 parts; 16 parts of a polar additive; cast solution viscosity of the film was 9000 cps; organic solvent is N- methylpyrrolidone; polar additive is glycerol, a mixture of polyvinyl alcohol and the amide N-2- propan-hydroxybutyl azobis methyl, mass ratio of 2: 1 :1;

[0090] S2: The film was immersed together with the support for 50 seconds was cured, a cured film was invade the interior and gradually spread, and further cured to form a separation layer and a prefiltration layer; solidifying liquid comprising water and ethylene glycol penetration additives, osmotic additive content of 60%; liquid temperature curing is 30 ℃, the support temperature is 10 ℃...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Average pore size | aaaaa | aaaaa |

| Average pore size | aaaaa | aaaaa |

| Average pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap