Flexible mesh belt type air suspension tea leaf sorting equipment

A technology of air suspension and flexible net, which is applied in lighting and heating equipment, separating solids from solids with airflow, solid separation, etc. It can solve the problems that tea cannot be sieved and collected, so as to facilitate further processing and improve Uniformity, the effect of reducing manpower and material resources

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

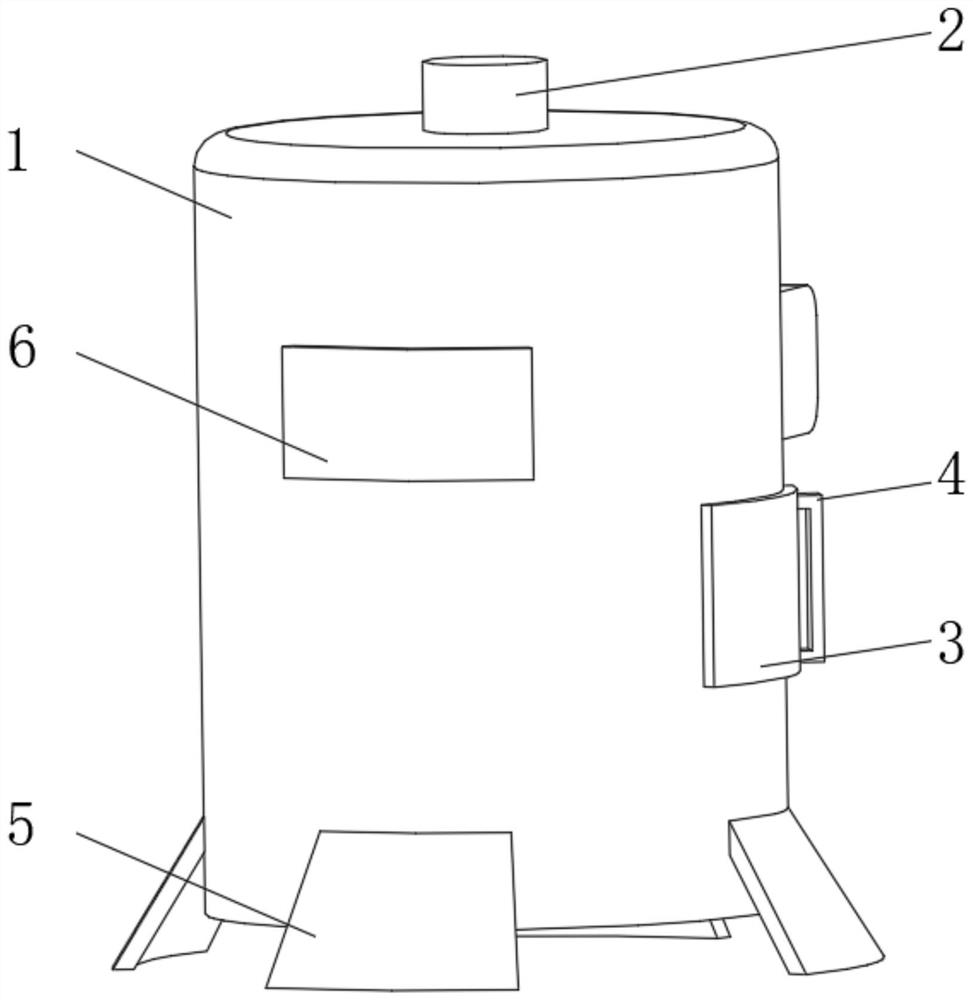

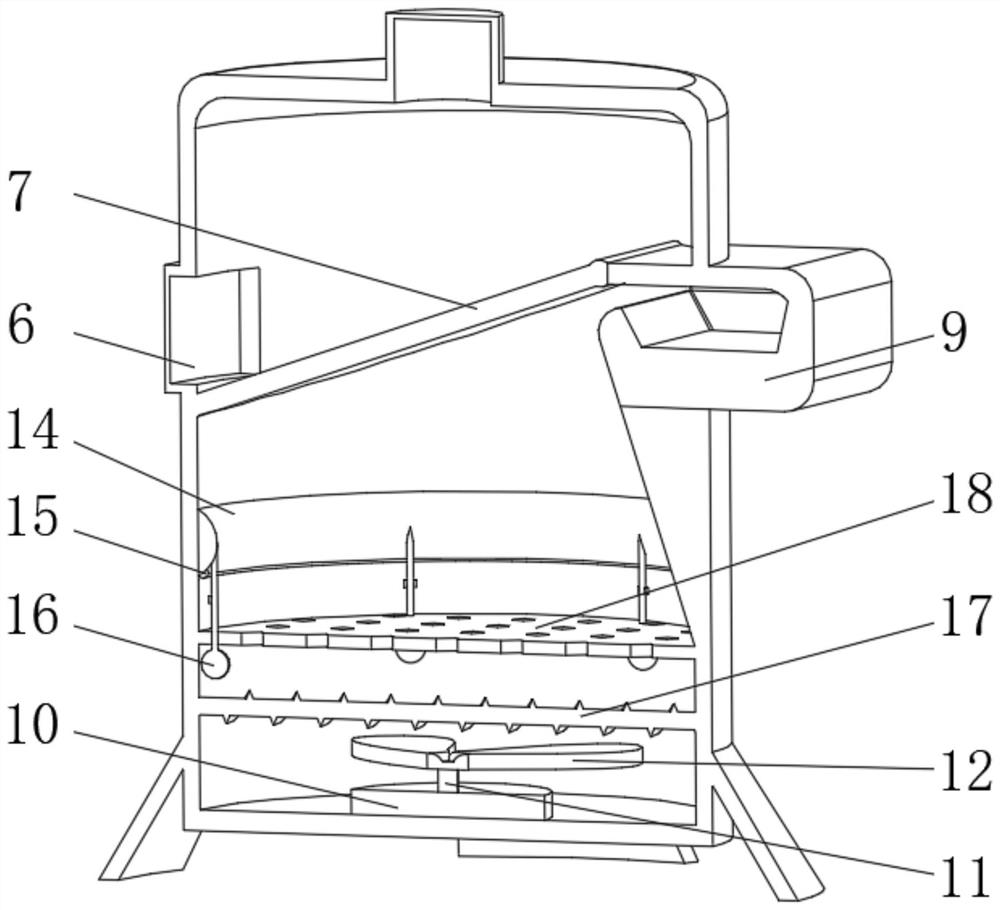

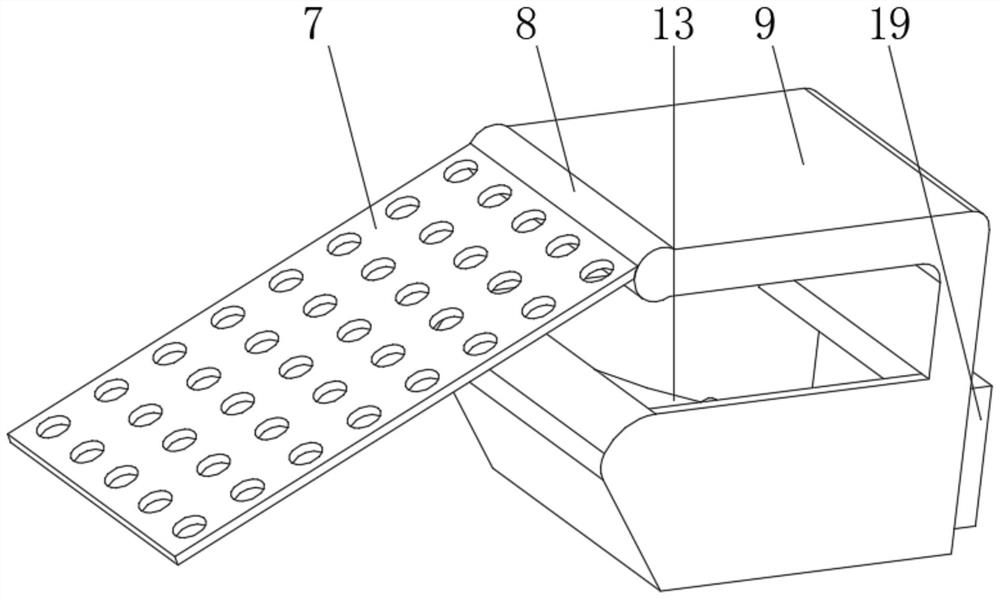

[0028] see Figure 1-4 , the present invention provides a technical solution: a flexible mesh-belt type air-suspension tea sorting equipment, comprising a drying air cylinder 1, the top of the drying air cylinder 1 is connected with a dust discharge pipe 2, and a part of the drying air cylinder 1 A movable door 3 is installed on the side, and the outer side of the movable door 3 is fixedly connected with a door handle 4. The side of the drying air duct 1 away from the dust discharge pipe 2 is evenly equipped with a support base 5, and the side of the drying air duct 1 is provided with a A flexible mesh belt 7 is installed on the inner wall of the drying air cylinder 1 close to the material inlet 6. The surface of the flexible mesh belt 7 is provided with screening holes. The flexible mesh belt 7 is far away from the side of the drying air cylinder 1. A connecting block 8 is fixedly connected, a collection frame 9 is installed on the side of the connecting block 8 away from the...

Embodiment 2

[0035] see Figure 1-5 , the present invention provides a technical solution: on the basis of Embodiment 1, an airbag device 16 is installed on the outside of the fixed ring 14, the airbag device 16 includes a hollow ball 161, and the bottom of the hollow ball 161 is evenly equipped with a heat conducting sheet 162, and the hollow The inside of the ball 161 is equipped with an elastic air bag 163, and one side of the hollow ball 161 is slidably connected with an extrusion plate 164, and one side of the extrusion plate 164 runs through the hollow ball 161, and the side of the extrusion plate 164 away from the hollow ball 161 is connected with the fixed ring. 14 is slidably connected, and an extrusion limiting plate 165 is installed on the outside of the extruding plate 164 close to the position of the ventilation net 18.

[0036] A spring 166 is installed symmetrically on the outside of the squeeze plate 164, and one end of the spring 166 away from the squeeze plate 164 is fixe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com