Coiling forming control device and method for hot coiling box

A technology of a control device and a control method, which is applied in the field of steel rolling in metallurgical enterprises, can solve problems such as position uncertainty, unwinding and slipping, and undetectable problems, and achieve the effect of eliminating hooked coils and elliptical coils

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

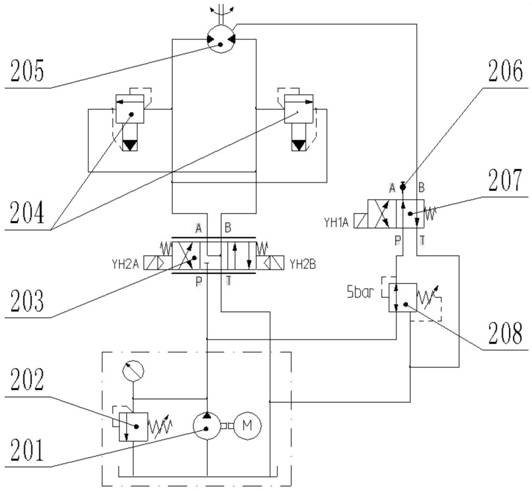

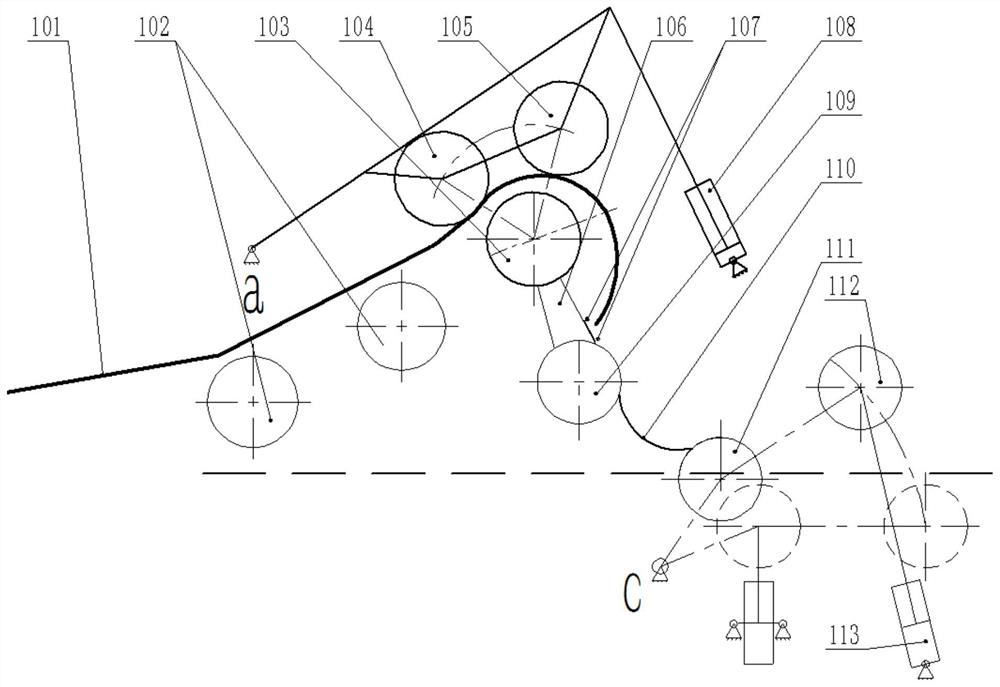

[0026] Embodiment 1: see figure 1 , a coiling and forming control device for a hot coil box, the control device includes a deflection roller 102, a lower bending roller 103, a 1# upper bending roller 104, a 2# upper bending roller 105, an inclined guide plate 106, a laser detection line 107, an oil cylinder 108, forming roller 109, arc-shaped guide plate 110, 1# idler roller 111, 2# idler roller 112, 2# idler roller oil cylinder 113, hydraulic motor 205 and hydraulic system; the lower bending roller 103 is installed on the arch and is fixed 1# upper bending roller 104 and 2# upper bending roller 105 are installed on the pinch roller frame, the oil cylinder 108 can drive the pinch roller frame to lift and drop the two rollers around the fulcrum a, 1# upper bending roller 104 and 2# The upper bending roller 105 and the lower bending roller 103 respectively form a certain roll gap S; the inclined guide plate 106 is installed between the lower bending roller 103 and the forming ro...

Embodiment 2

[0027] Example 2: see figure 1 , figure 2 , a hot coil box coiling forming control method, the method is as follows:

[0028] Step 1: adjust the roll gap of the bending roll according to the signal of the laser detection line 107 to ensure that the head of the strip hits the lower third of the inclined guide plate 106;

[0029] Step 2: drive control of the hydraulic motor 205;

[0030] Step 3: Optimization of speed during coiling.

[0031] As an improvement of the present invention, the first step: adjust the roll gap of the bending roll according to the signal of the laser detection line 107 to ensure that the head of the strip hits the lower third of the inclined guide plate 106; there are three types of signals from the upper and lower laser detection lines 107 Possible combinations:

[0032] 1) When the signals of the upper and lower laser detection lines 107 are both 0, that is, the head of the strip steel 101 hits the middle and upper part of the inclined guide plat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com