Flexible printing equipment and printing method thereof

A flexographic printing and equipment technology, applied in printing, printing presses, rotary printing presses, etc., can solve the problems of single sliding path of the embossing roller, unfavorable flexographic printing accuracy, complex equipment structure, etc., so as to avoid poor printing effect and satisfy individual needs Printing demand, the effect of improving printing efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

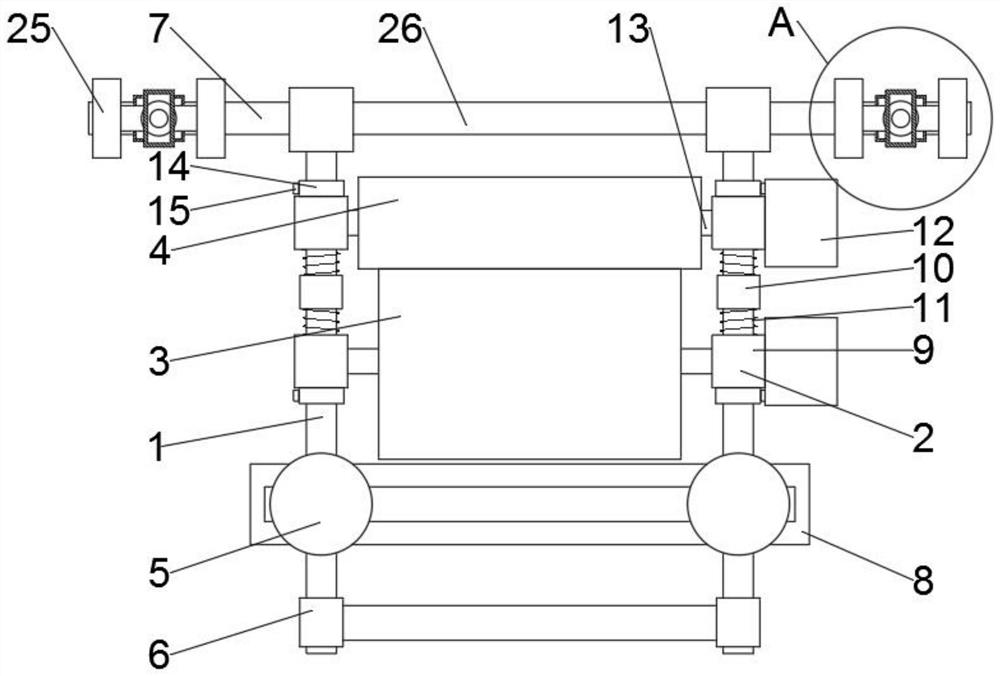

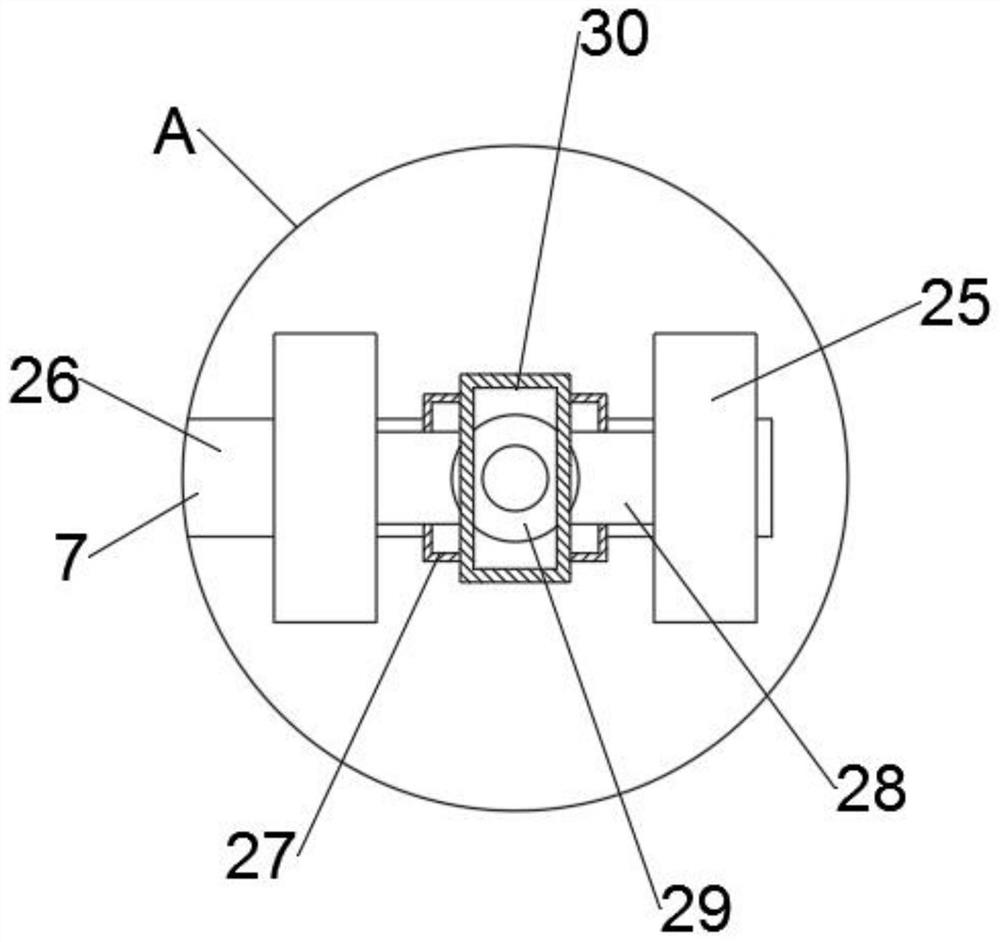

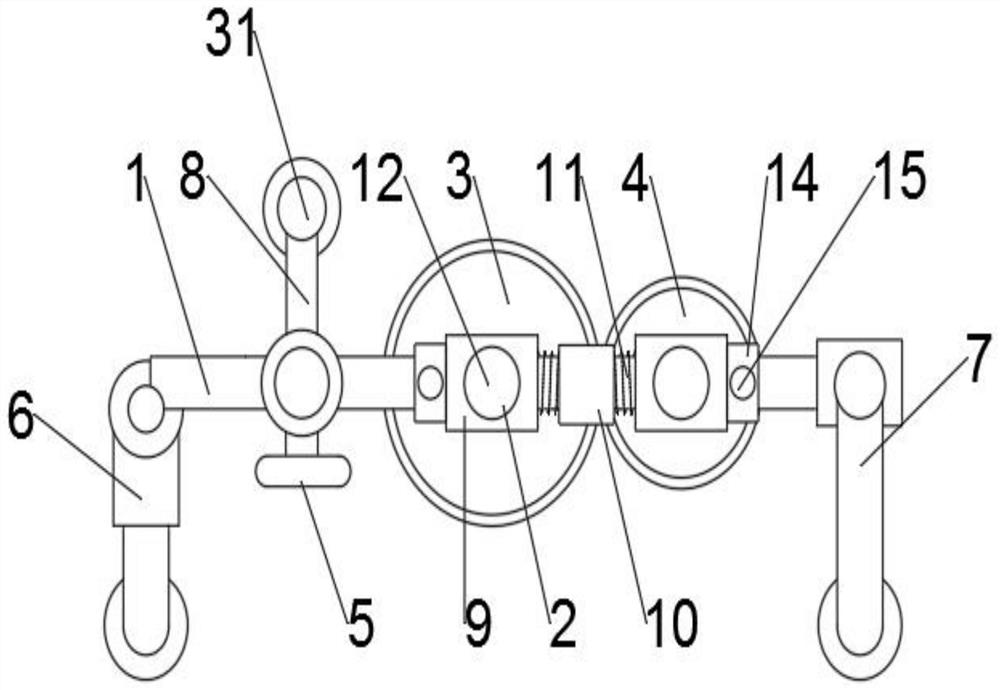

[0034] Such as figure 1 As shown, a flexible printing device proposed by the present invention includes a frame 1, an adjustment assembly 2, an embossing roller 3, an ink roller 4, a protection member 5, a No. 1 support assembly 6, a No. 2 support assembly 7, and a pressure assembly 8 And the positioning assembly 34; the adjustment assembly 2 is arranged on the frame 1; the embossing roller 3 and the ink roller 4 are arranged on the frame 1 through the rotation of the adjustment assembly 2; the protection member 5 is arranged on the frame 1; the No. 1 support assembly 6 and No. 2 support assembly 7 are respectively arranged at the two ends of frame 1; No. 1 support assembly 6 is arranged at one end of frame 1 close to embossing roller 3; Pressure assembly 8 is arranged on frame 1, and pressure assembly 8 and protective member 5 are respectively located on both sides of the frame 1; the positioning component 34 is arranged on the adjustment component 2 and is slidably connected...

Embodiment 2

[0037] Such as figure 1 As shown, a flexible printing device proposed in this embodiment, compared with Embodiment 1, the adjustment assembly 2 includes a sliding seat 9, a connecting block 10, a No. 1 spring 11, a driving member 12, a rotating shaft 13, a sliding block 14 and a positioning Bolt 15; sliding seat 9 is provided with multiple sets, and multiple sets of sliding seat 9 are slidably arranged on the frame 1; connecting block 10 is slidably arranged on the frame 1, and is located between multiple sets of sliding seats 9; No. 1 spring 11 sliding sleeve Located on the frame 1, one end of the No. 1 spring 11 is arranged on the connecting block 10, and the other end is arranged on the sliding seat 9; the sliding block 14 is arranged on the sliding seat 9; the positioning bolt 15 is arranged on the sliding block 14, and Slidingly connected with the frame 1; the rotating shaft 13 driven by the driving member 12 is rotated and set on the sliding seat 9;

[0038]The sliding ...

Embodiment 3

[0040] Such as figure 1 As shown, in the flexible printing equipment proposed in this embodiment, compared with the first embodiment, the protection member 5 is set as an elastic protection pad.

[0041] Protector 5 is set to prevent frame 1 from bottoming out.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com