Novel device for fully utilizing remaining kinetic energy of ventilation air methane and use method of novel device

A new type of kinetic energy technology, applied in steam engine installations, earthwork drilling, machines/engines, etc., can solve the problems of polluted air affecting the environment, inability to be fully utilized, energy waste, etc., to achieve stable power supply, ensure mine work efficiency, and improve The effect of economic benefits

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

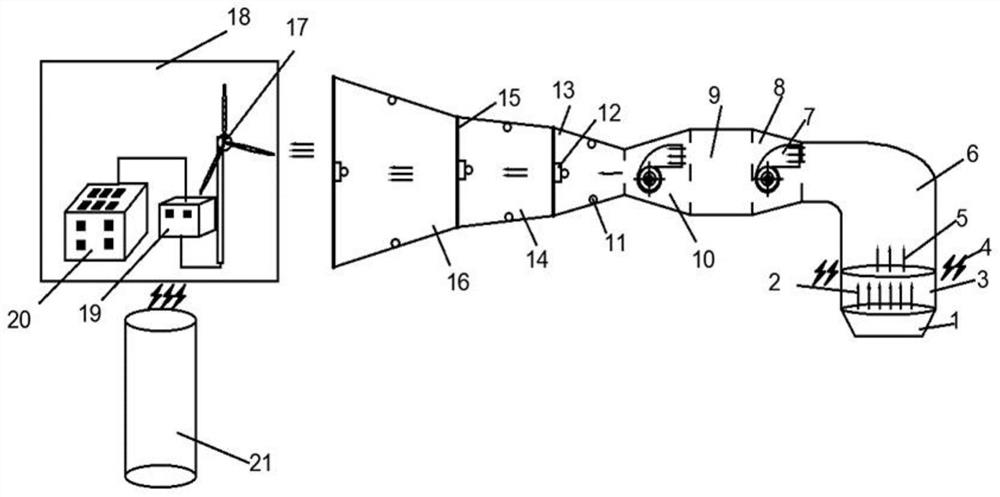

[0028] Please refer to the attached figure 1 , the purpose of this embodiment is to provide a new type of device that makes full use of the remaining kinetic energy of the exhaust wind, including: a transmission pipeline, a wind generator 18 and a plurality of one-way pressure sensing valves, and the exhaust wind is adjusted to drive wind power generation through the transmission pipeline Machine 18 generates electricity.

[0029]Among them, the delivery pipeline is composed of a front steady flow acceleration pipeline and a rear energy storage pipeline; wherein, the front steady flow acceleration pipeline is sequentially provided with a first steady flow tube 6, a first diffuser 8, and a second steady flow tube 9 And collector 10; the second diffuser 13, the third diffuser 14 and the fourth diffuser 16 are arranged in sequence in the rear energy storage pipeline, the second diffuser 13, the third diffuser 14 and the fourth diffuser 16 A pressure sensor 11, an intelligent ins...

Embodiment 2

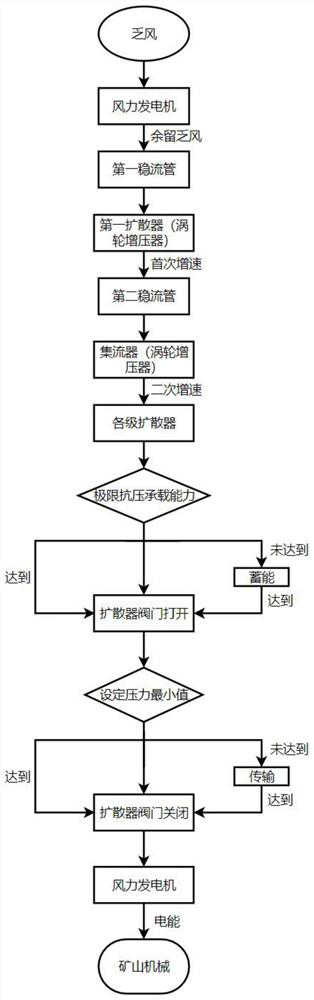

[0036] Please refer to the attached figure 2 , the purpose of this embodiment is to provide a method for using a novel device that makes full use of the remaining kinetic energy of exhaust air, including the following steps:

[0037] Step 1: The energy in the mine exhaust air is generated through the first conversion device 3, and the remaining exhaust air 5 is received by the first steady flow pipe 6 to make the exhaust air reach a relatively stable speed, and then transmitted to the first diffuser 8, and the first diffuser 8 is used to A turbocharger 7 inside a diffuser 8 accelerates the exhaust air, so that the exhaust air has a certain speed, and then stabilizes the wind speed through the second steady flow tube 9, and then uses the collector 10 and the turbocharger 7 therein to Increase the wind speed and concentrate the wind energy;

[0038] Step 2: After accelerating the exhaust air through the collector 10, continue to store energy and transmit the exhaust air to the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com