A multi-injector group enhanced co 2 Dual temperature refrigeration system

A refrigeration system and ejector technology, applied in evaporator/condenser, refrigerator, refrigeration components, etc., can solve the problem of large throttling loss, and achieve the effect of recovering throttling loss, reducing quantity, and improving heat exchange efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

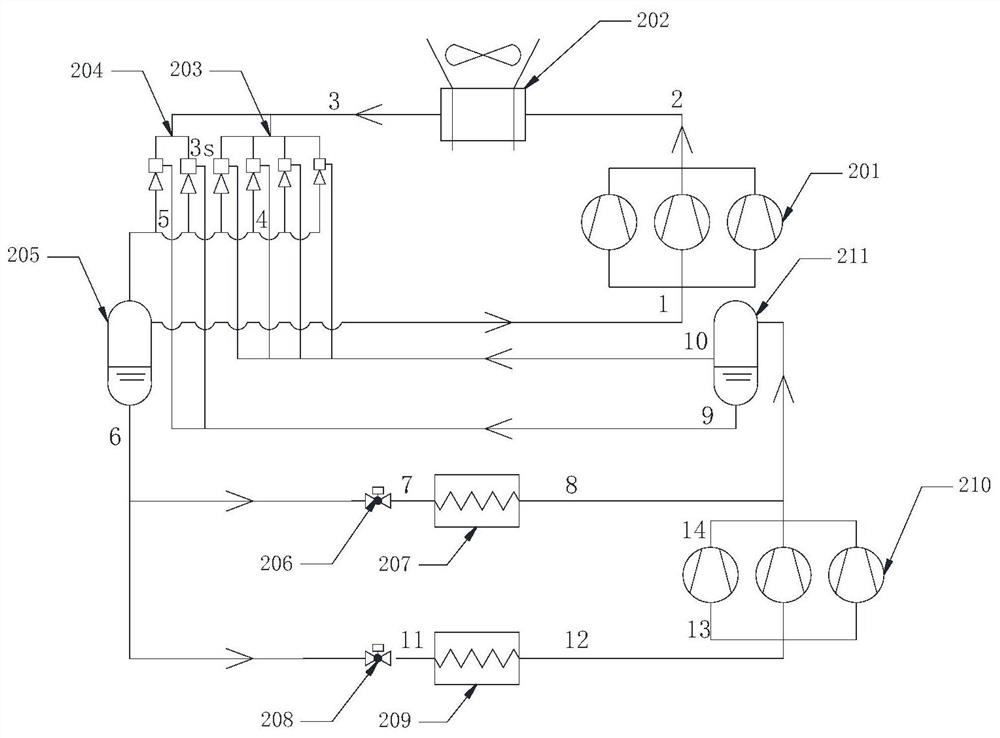

[0023] The present invention will be described in further detail below in conjunction with the accompanying drawings and specific embodiments.

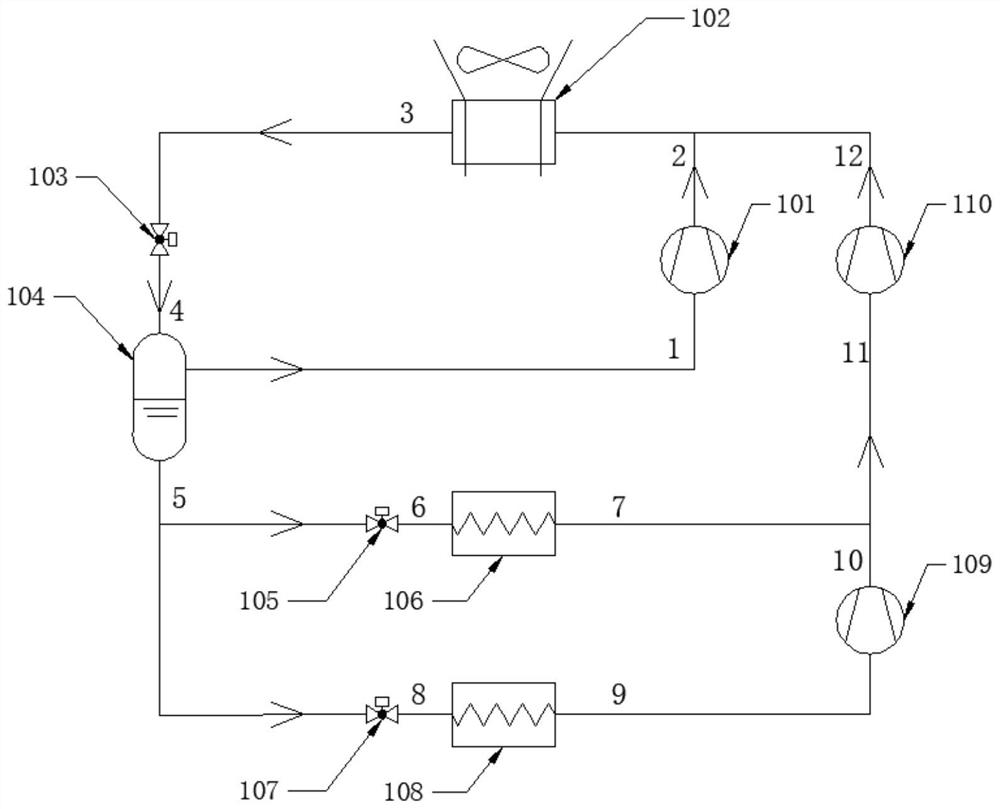

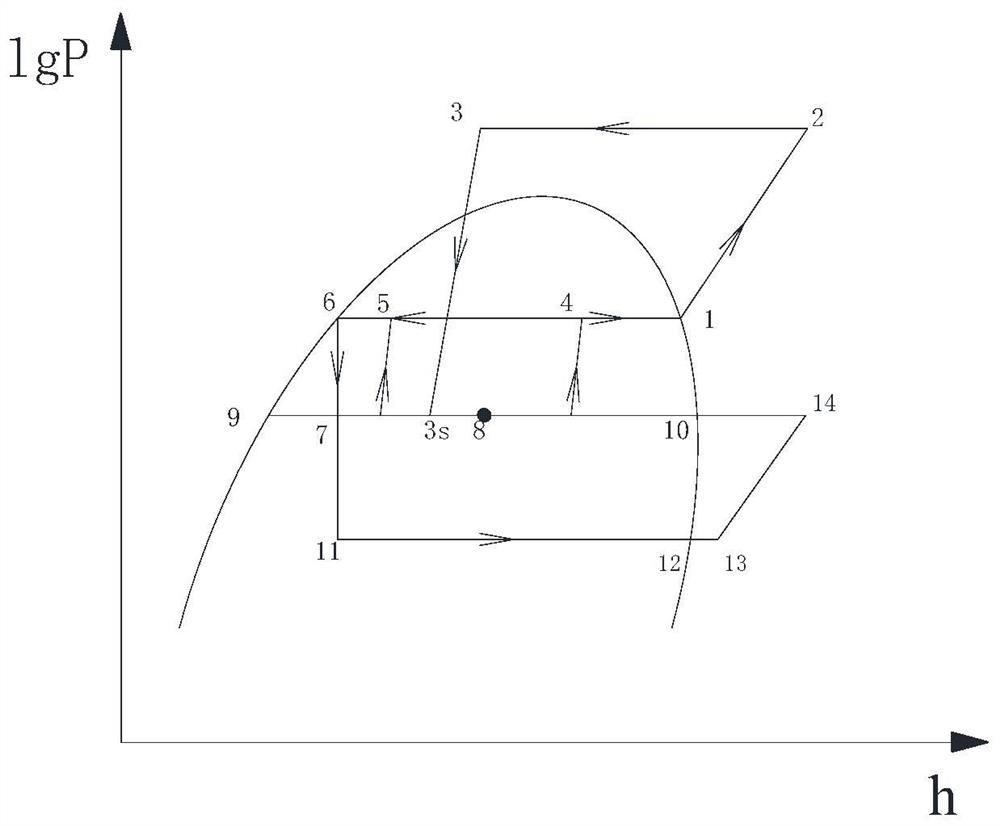

[0024] Such as figure 2 As shown, a multi-injector group enhanced CO of the present invention 2 Dual temperature refrigeration system, including:

[0025] High temperature compressor, gas cooler, gas-gas ejector group, gas-liquid ejector group, gas-liquid separator, first throttle valve, medium temperature evaporator, second throttle valve, low temperature evaporator, low temperature compressor , Liquid reservoir.

[0026]The high-temperature compressor is a CO2 transcritical compressor, and its outlet is connected to the inlet of the gas cooler; the outlet of the gas cooler is divided into two routes, one of which is connected to the first inlet of the gas-gas injector group, and the other is connected to the gas-gas ejector group. The first inlet of the liquid ejector group is connected; the second inlet of the gas-gas ejector g...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com