Box type high-temperature degradation furnace

A high-temperature degradation, box-type technology, applied in the direction of furnaces, furnace components, furnace types, etc., can solve the problems of insufficient energy saving and environmental protection, low heat utilization rate, etc., and achieve good heating effect and high heat transfer efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

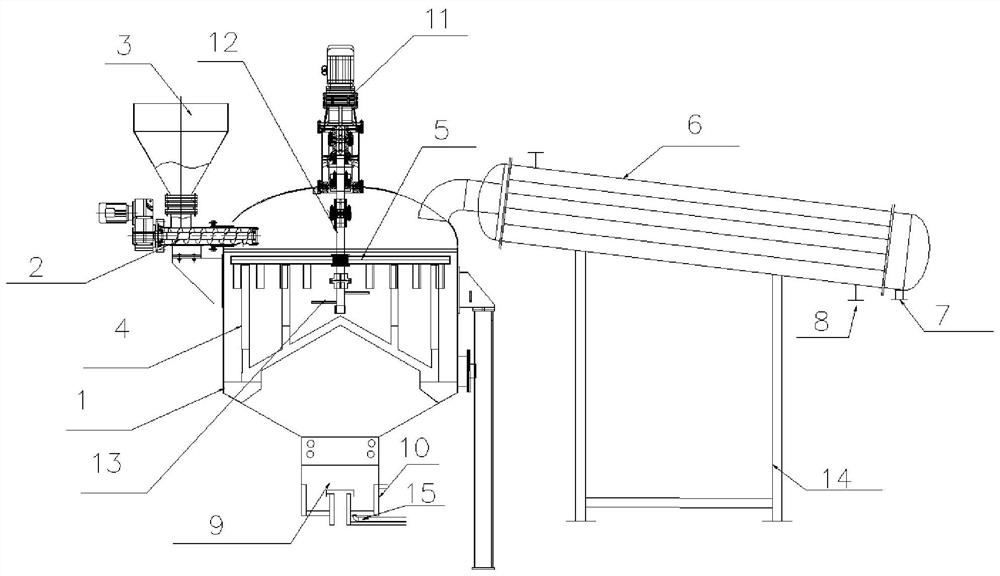

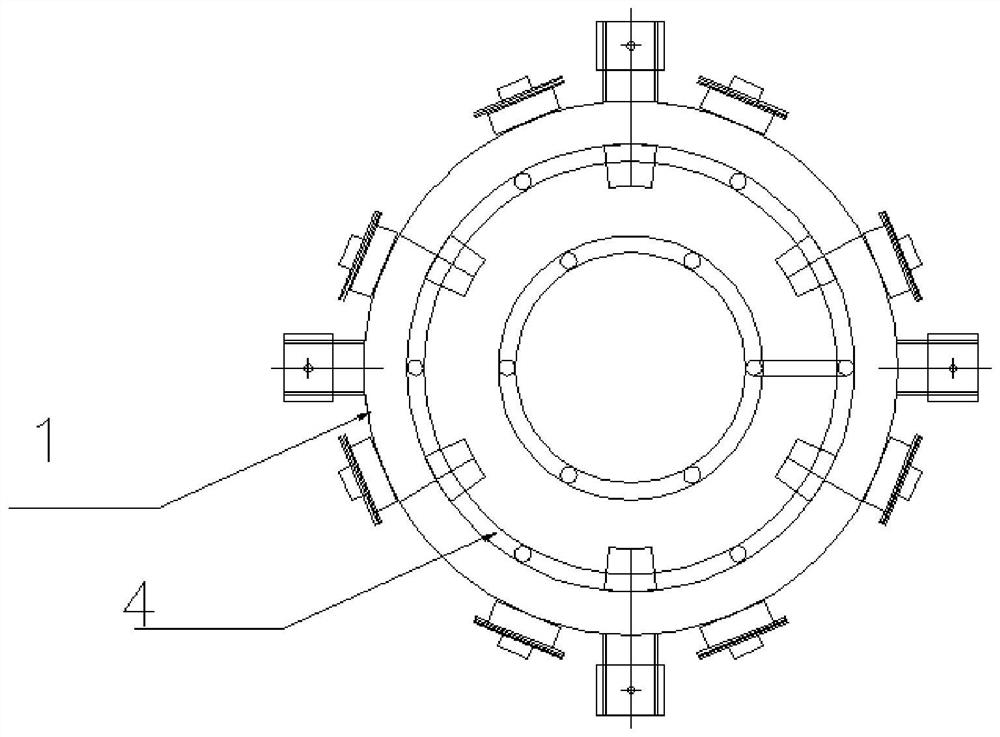

[0033] A box-type high-temperature degradation furnace, comprising a furnace body, the top of the furnace body is provided with a screw conveying mechanism, the discharge end of the spiral conveying mechanism communicates with the furnace body, and the feeding end of the spiral conveying mechanism communicates with a storage A feed bin, the furnace body is provided with a heater, the heater is a heating box, the heating box is connected with a heating pipe, the heating box is provided with a heating medium, and the furnace body is provided with a stirrer, The furnace body is located above the heating box and is also provided with a material distributor. The top of the furnace body is connected to a condenser, and the condenser is provided with a material outlet and a cooling water port. The bottom of the furnace body is also provided with a slag extractor. .

[0034] Through this setting, the plexiglass waste in the storage bin is sent into the furnace body through the screw c...

Embodiment 2

[0036] On the basis of Example 1, the heating medium is heat conduction oil and molten salt. With this setting, the heat transfer oil and molten salt are used as the heating medium, the heating effect is good, and the heat transfer efficiency is higher.

Embodiment 3

[0038] On the basis of the above embodiments, a heating medium heater is provided at the inlet end of the heating pipe at the bottom of the furnace body next to the slag extractor.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com