Full-automatic optical fiber core flexible metal sleeve high-speed armoring machine and optical cable armoring method

A technology of metal sleeves and optical fiber wires, applied in fiber mechanical structures, light guides, optics, etc., can solve the problems of slow armoring speed, difficult material control, and low efficiency, and achieve the goal of reducing armoring costs and increasing armoring speed Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] The implementation of the present invention will be described in detail below in conjunction with the accompanying drawings. The accompanying drawings are only for reference and description, and do not constitute a limitation to the protection scope of the present invention.

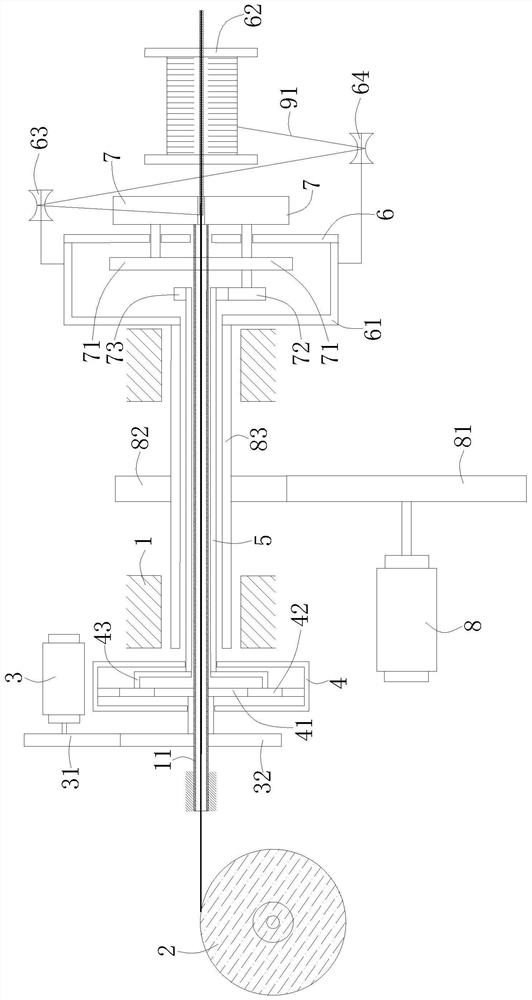

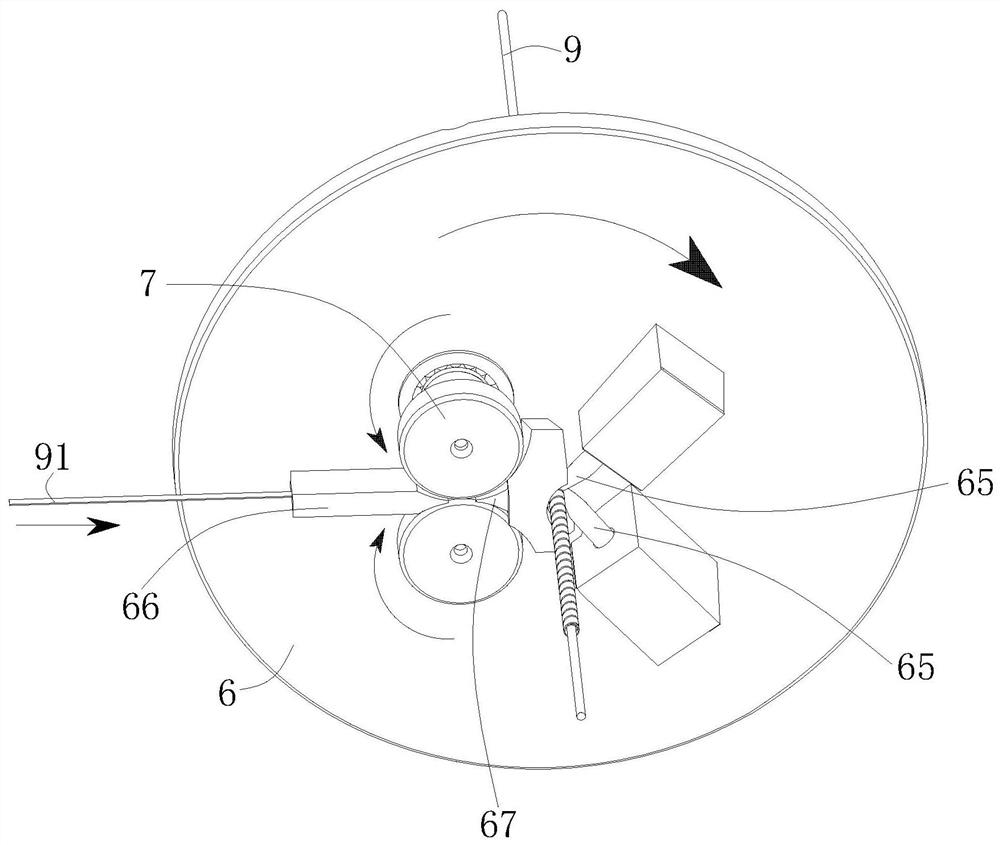

[0029] refer to figure 1 with figure 2 , a fully automatic optical fiber core flexible metal casing high-speed armoring machine, comprising a machine base 1, an optical fiber reel 2, a main template 6, a main drive mechanism, a steel tape reel 62 and a forming drive mechanism, the machine base 1 Conduit 11 is installed on the top, optical fiber reel 2 is arranged at intervals at the inlet end of conduit 11, main template 6 is rotatably set on the discharge end of conduit 11, and the main driving mechanism is arranged on the side of conduit 11 and is connected with The main formwork 6 is connected by transmission, and the steel strip reel 62 is rotatably connected to the main formwork 6. The stee...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com