Irradiation test tube underwater cutting device

A cutting device and irradiation technology, which is applied in the field of irradiation experiments, can solve the problems of difficult transportation and the inability of large and long irradiation test target components to enter the hot chamber normally, and achieves the effect of reducing research requirements.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

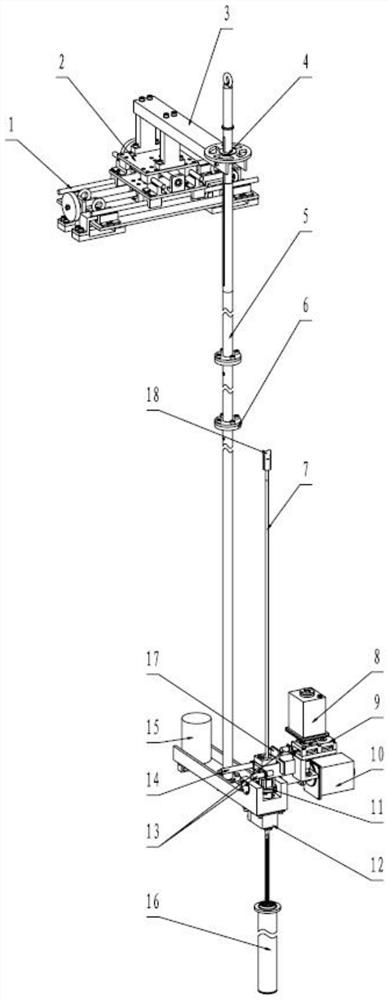

[0072] In view of the above problems, this embodiment provides an underwater cutting device for irradiation test tubes, including a three-dimensional adjustment platform, a coupling rod 5 , a support platform, a cutting assembly and a grabbing assembly 18 .

[0073] The three-dimensional adjustment platform is fixed on the water surface, because the irradiation test tube 7 to be cut needs to be set at 8000mm underwater, and the length of the irradiation test tube 7 to be cut is 4000mm, so the specific length needs to be selected by those skilled in the art , and the corresponding water tank can be set to realize the water surface.

[0074] The connecting rod 5 is vertically arranged, the upper end of the connecting rod 5 is fixedly connected with the three-dimensional adjustment platform, the supporting platform is arranged under the water surface, and the supporting platform is fixedly connected with the lower end of the connecting rod 5;

[0075] The three-dimensional adjust...

Embodiment 2

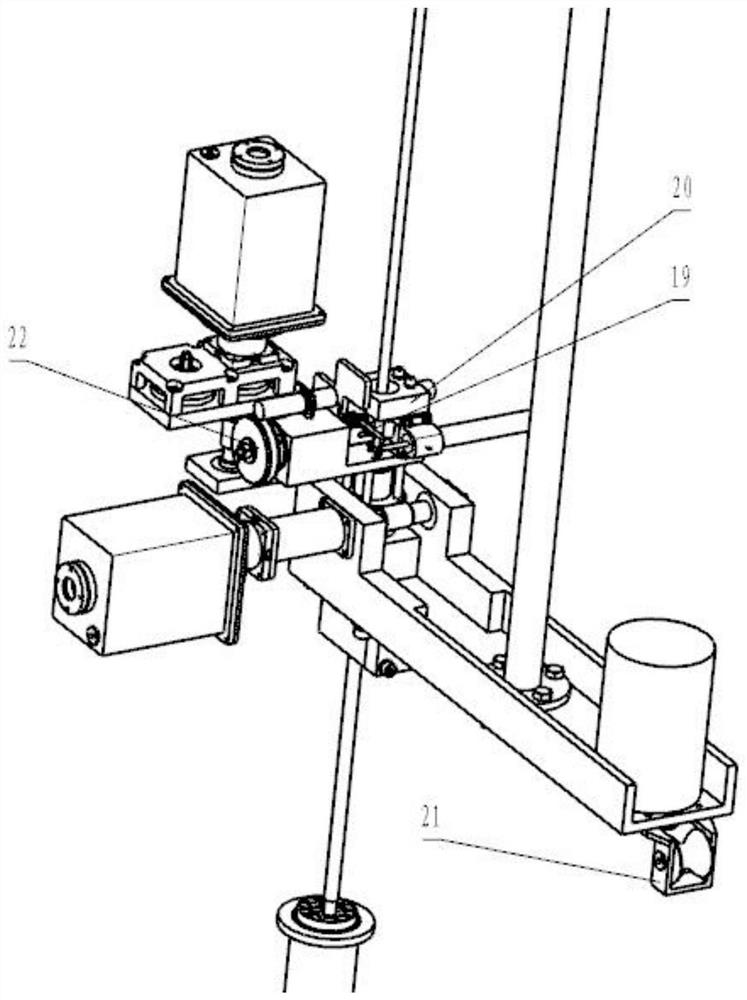

[0080] This embodiment explains the specific structure of the three-dimensional adjustment platform. For the convenience of description, an XYZ coordinate system is set, that is, a direction located on the horizontal plane is set as the X axis, and a direction located on the horizontal plane and perpendicular to the X axis is set as Y Axis, set the vertical direction and the direction perpendicular to both the X-axis and the Y-axis is the Z-axis;

[0081] The three-dimensional adjustment platform includes an X-axis moving assembly 1 , a Y-axis moving assembly 2 and a Z-axis moving assembly 5 .

[0082] The X-axis moving assembly 1 has a fixed end and a moving end, and the moving end of the X-axis moving assembly 1 moves along the X-axis;

[0083] The Y-axis moving assembly 2 has a fixed end and a moving end, the moving end of the Y-axis moving assembly 2 moves along the Y-axis, and the fixed end of the Y-axis moving assembly 2 is fixedly connected to the moving end of the X-ax...

Embodiment 3

[0102] This embodiment provides a one-circle structure of the connecting rod 5, which is a three-section structure, including an upper segment rod, a middle segment rod and a lower segment rod, generally 8.5m in length.

[0103] The upper segment rod is vertically arranged, and the upper end of the upper segment rod is fixedly connected with the moving end of the Z-axis moving assembly 5;

[0104] The middle rod is vertically arranged, and the upper end of the middle rod is detachably connected with the lower end of the upper rod through the connecting flange 6;

[0105] The lower section bar is vertically arranged, and the upper end of the lower section bar is detachably connected with the lower end of the middle section bar through the connecting flange 6, and the lower end of the lower section bar is fixedly connected with the support platform.

[0106] The upper rod, middle rod and lower rod are detachably connected through the connecting flange 6, so that in the process o...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com