Sewage treatment system and process utilizing filamentous bacteria and controlling sludge bulking

A sewage treatment system and sludge bulking technology, applied in water/sludge/sewage treatment, water/sewage treatment, water/sewage multi-stage treatment, etc., to reduce energy consumption, improve biochemical treatment efficiency, improve effluent water quality and The effect of compliance rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

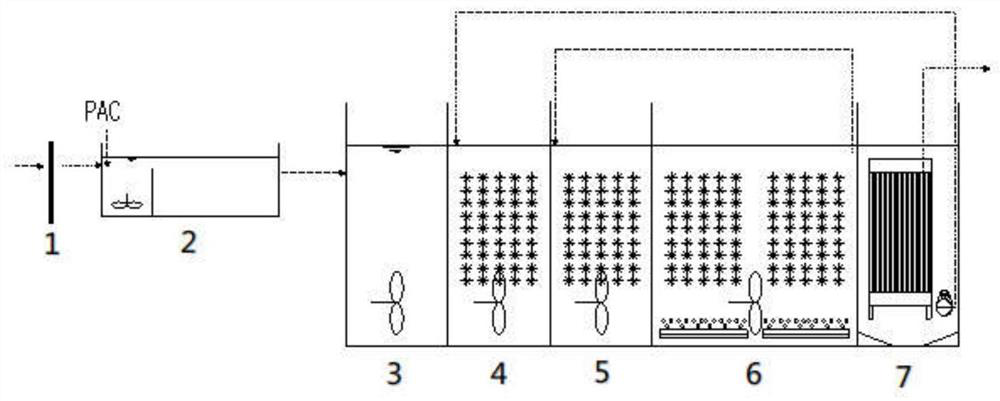

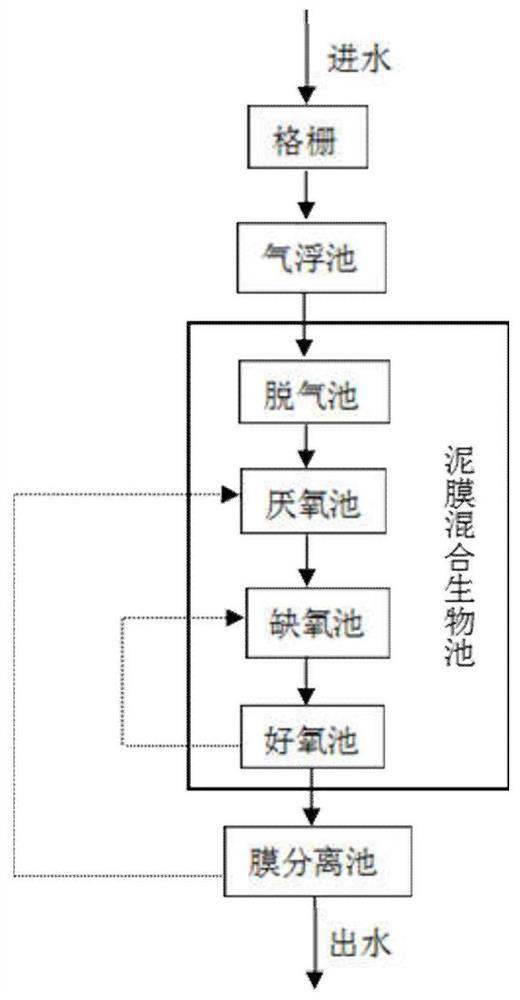

[0026] Embodiment 1 of the present invention: a sewage treatment system utilizing filamentous bacteria and controlling sludge bulking:

[0027] Including grid 1, air flotation tank 2, mud film mixed biological tank and membrane separation system 7 connected in sequence; said mud membrane mixed biological tank includes degassing tank 3, anaerobic tank 4, anoxic tank 5 and aerobic tank 6 ; The bottom of the degassing tank 3 is provided with a stirring paddle; a sludge return pipe and a return pump are provided between the membrane separation system 7 and the anaerobic tank 4; There is a sludge return pipe; the air flotation tank 2 is connected with a PAC dosing device; the anaerobic tank 4, the anoxic tank 5, and the aerobic tank 6 are equipped with fixed biological fillers; the anaerobic tank 4 and the anoxic tank The inside of the tank 5 is provided with a flow device; the bottom of the aerobic tank 6 is provided with an aerator; the membrane separation system 7 includes a mem...

Embodiment 2

[0028] Embodiment 2: A sewage treatment system utilizing filamentous bacteria and controlling sludge bulking:

[0029] Including grid 1, air flotation tank 2, mud film mixed biological tank and membrane separation system 7 connected in sequence; said mud membrane mixed biological tank includes degassing tank 3, anaerobic tank 4, anoxic tank 5 and aerobic tank 6 .

Embodiment 3

[0030] Embodiment 3: A sewage treatment system utilizing filamentous bacteria and controlling sludge bulking:

[0031] Including grid 1, air flotation tank 2, mud film mixed biological tank and membrane separation system 7 connected in sequence; said mud membrane mixed biological tank includes degassing tank 3, anaerobic tank 4, anoxic tank 5 and aerobic tank 6 ; The bottom of the degassing tank 3 is provided with a stirring paddle; a sludge return pipe and a return pump are provided between the membrane separation system 7 and the anaerobic tank 4; There is a sludge return pipe.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com