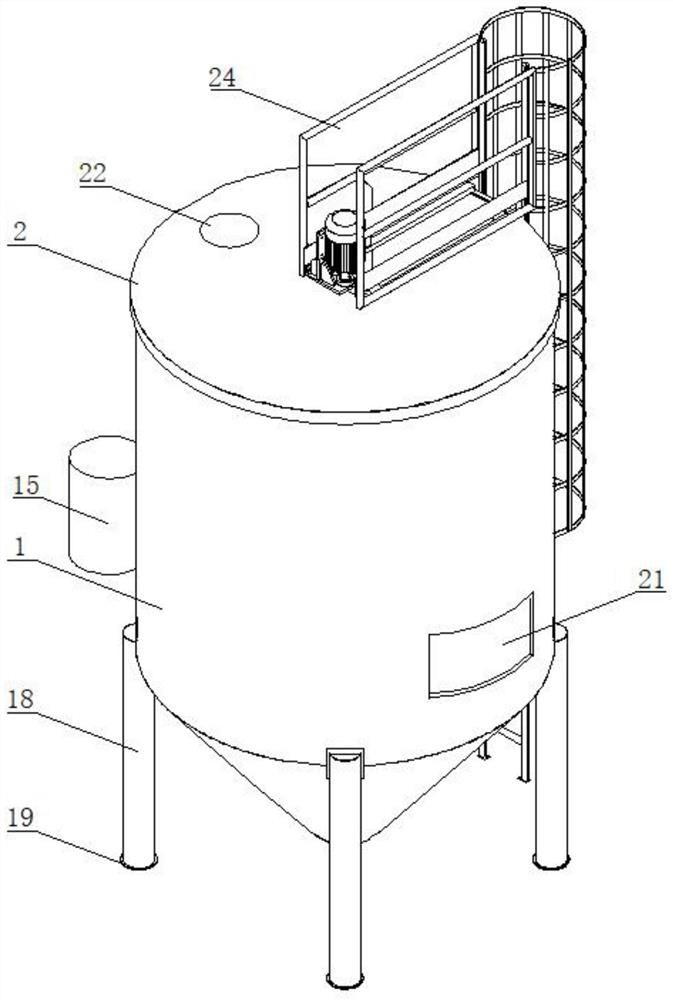

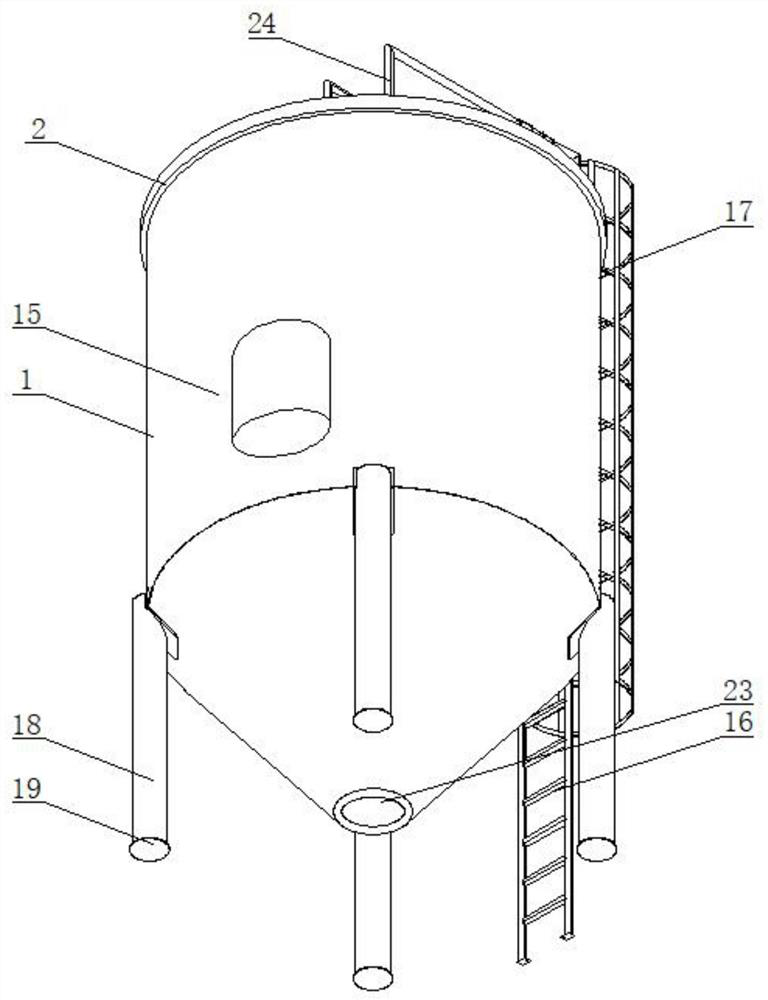

Organic fertilizer compost stirring device

A stirring device and organic fertilizer technology, which is applied in the direction of fertilization device, organic fertilizer, organic fertilizer equipment, etc., can solve the problems of affecting composting efficiency, high labor intensity, and inconvenient composting of organic fertilizer, so as to improve composting efficiency and reduce composting cost , the effect of simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

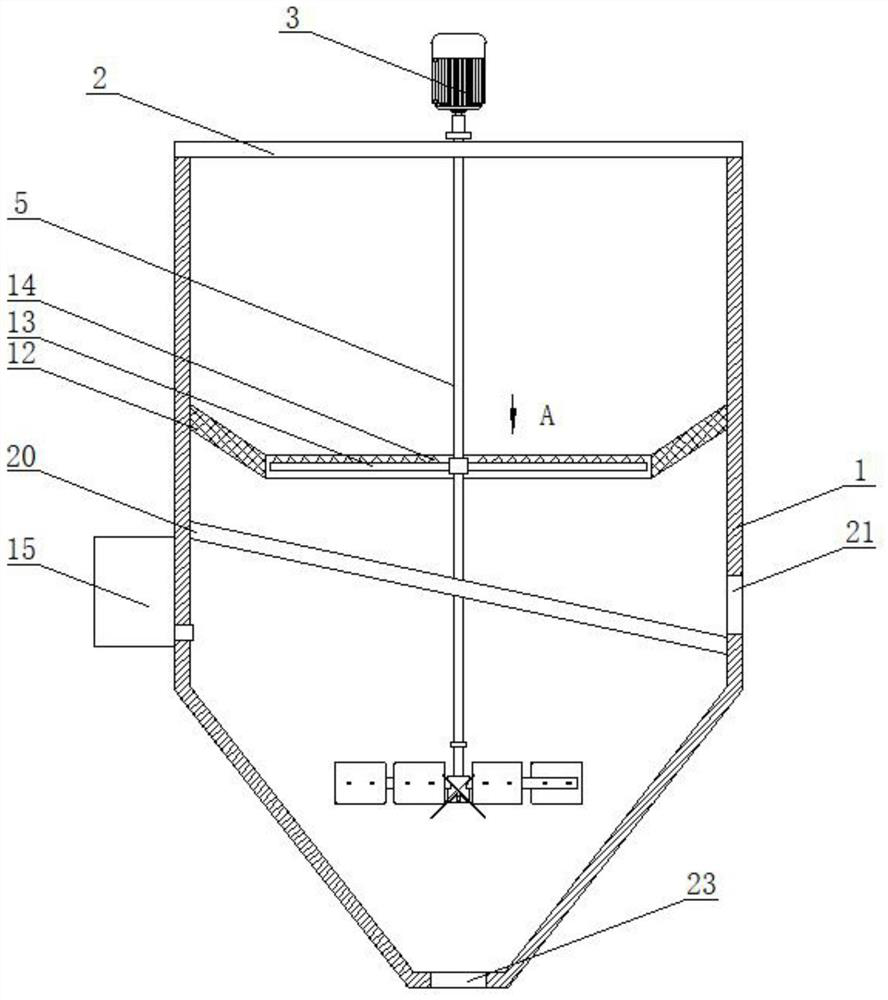

[0031] When using this device, first pass plant matter such as crop stalks, green manure, weeds, and soil, human excrement, garbage, etc. into the tank body 1. At the same time, the motor 3 is working, and the motor 3 is driven by the coupling 4. The rotating shaft 5 rotates, the rotating shaft 5 drives the cross bar 13 to rotate, the cross bar 13 rotates to drive the cutting blade 14 to rotate, and the cutting blade 14 rotates to cut and pulverize plant matter such as crop stalks, green manure, weeds, etc., due to inertia, Crop stalks, green manure, weeds and other plant substances are pushed by the cutting blade 14 to move towards the direction of the casing 12 while being crushed, and fall into the lower part of the tank body 1 through the hollow filter structure on the upper part of the casing 12, and the incomplete crushing The substance will approach the cutting blade 14 again under the action of its own gravity, and be crushed again by the cutting blade 14 until it can p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com