Waste resource recycling device for urban landscape gardens

A technology of waste resources and scenery, applied in the field of waste resource recycling, can solve the problems of inability to guarantee the complete crushing of waste, affecting extrusion molding, high labor intensity, etc., and achieve the effect of improving recycling effect, stable movement, and convenient composting and fermentation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

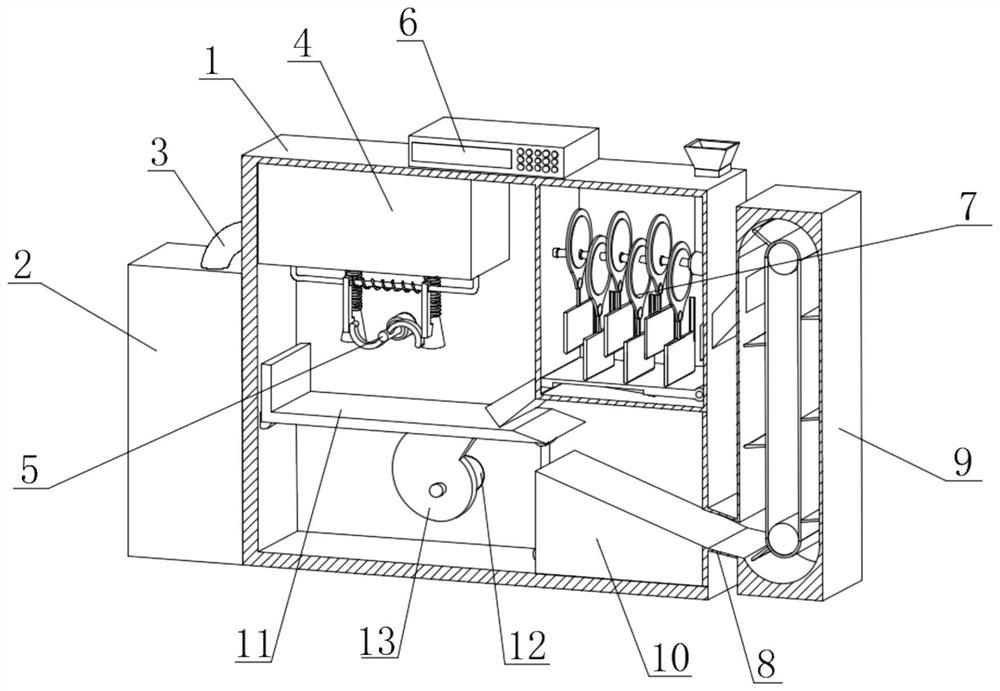

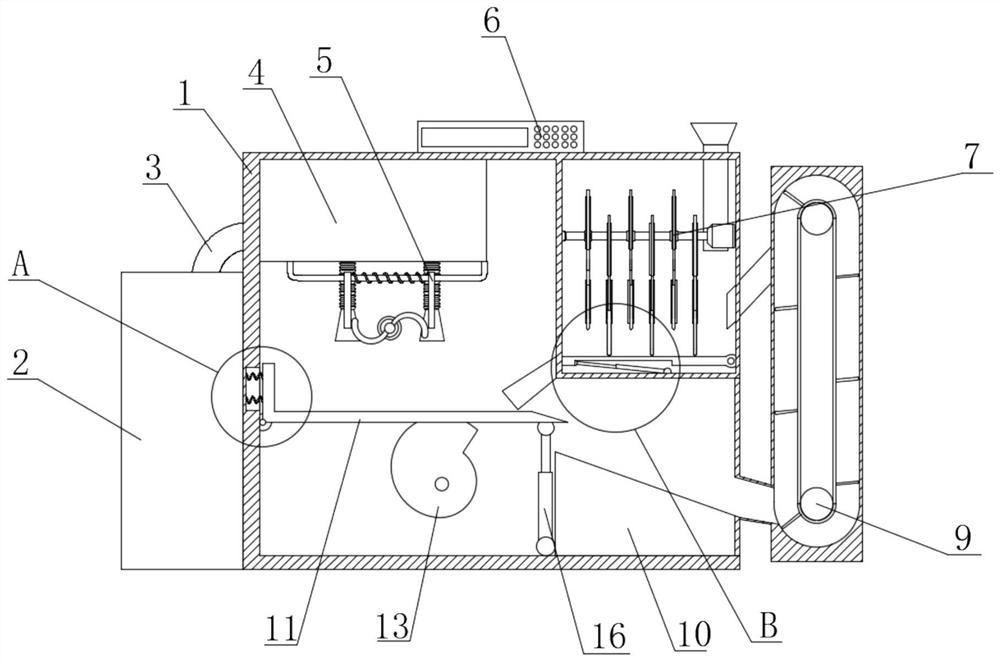

[0033] see Figure 1-Figure 6, the present invention provides a technical solution: a waste resource recycling device for urban landscape gardens, comprising a device body 1, a fan body 4 is fixedly connected to the top inner wall of the device body 1, and a mobile fan body 4 is fixedly connected to the bottom of the fan body 4 Device 5, a PLC controller 6 is fixedly connected to the top center of the device body 1, a crushing device 7 is fixedly connected to the top inner wall of the device body 1, and a circulation pipe 8 is fixedly connected to the outer wall of the device body 1 away from the stacking device 2. , one side of the circulation pipe 8 is fixedly connected with the circulation conveying device 9, the bottom inner wall of the device body 1 is fixedly connected with the material guide table 10, and one side of the material guide table 10 is communicated with one side of the circulation pipe 8. The large particles such as wood that are unloaded from the feeding ta...

Embodiment 2

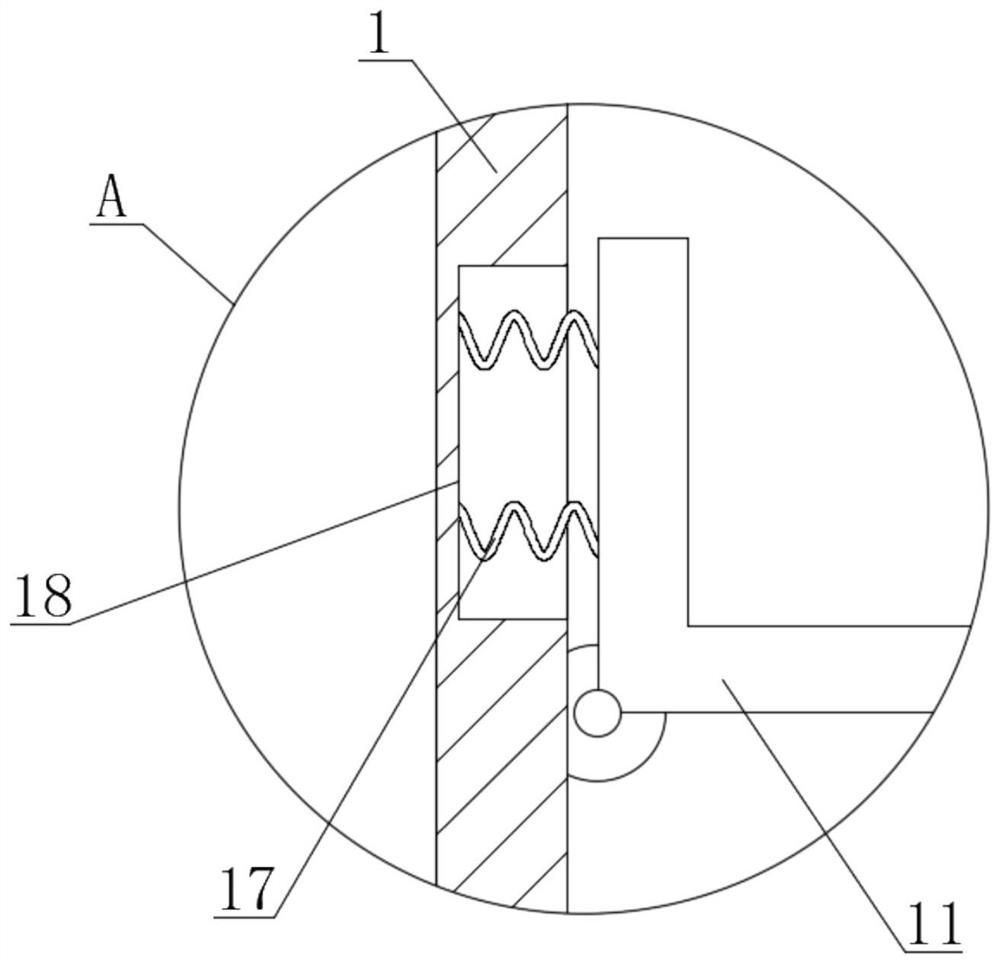

[0038] see Figure 1-Figure 2 and Figure 7 As shown, on the basis of the first embodiment, the present invention provides a technical solution: the moving device 5 includes a limit slide bar 501, the top of the limit slide bar 501 is fixedly connected with the bottom of the fan body 4, wherein the limit slide bar 501 is fixedly connected The rod 501 is fixedly connected with the fan body 4, which is convenient for stable placement. The outer wall of the limit slide rod 501 is sleeved with a telescopic spring 502, and the outer wall of the limit slide rod 501 is located at both ends of the telescopic spring 502. A fan head 504 is fixedly connected to the bottom of the block 503, and a fan pipe 505 is fixedly connected to the top of the fan head 504. The fan pipe 505 is an elastic pipe. 504 moves synchronously, which is convenient to drive the fan tube 505 to stretch back and forth, and at the same time does not prevent the fan body 4 from sucking the scraps. The inner wall of...

Embodiment 3

[0041] see Figure 8-Figure 9 As shown, on the basis of Embodiment 1 and Embodiment 2, the present invention provides a technical solution: a stacking device 2 is fixedly connected to one side outer wall of the device body 1, and a connecting pipe 3 is fixedly connected to the top of the stacking device 2 , a screening motor 12 is fixedly connected to the inner wall of one side of the device body 1 and located below the L-shaped plate 11, a cam 13 is connected to one side of the screening motor 12 in rotation, and a bottom groove 14 is opened at the bottom of the L-shaped plate 11. The cam The top of the cam 13 is in contact with the inner wall of the bottom groove 14, and the cam 13 will continuously contact the bottom groove 14 when it rotates. Since the position of the cam 13 and the motor shaft of the screening motor 12 does not change, the L-shaped plate 11 will gradually tilt. The side of the L-shaped plate 11 close to the inner wall of the device body 1 is fixedly conne...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com