High-speed warping device and method for high-strength glass fibers

A glass fiber and high-strength technology, applied in the field of high-strength glass fiber high-speed warping devices, can solve the problems of high yarn tension, high cost, and large degree of transformation, and achieve the effect of reasonable device structure, convenient manufacture, and small changes

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

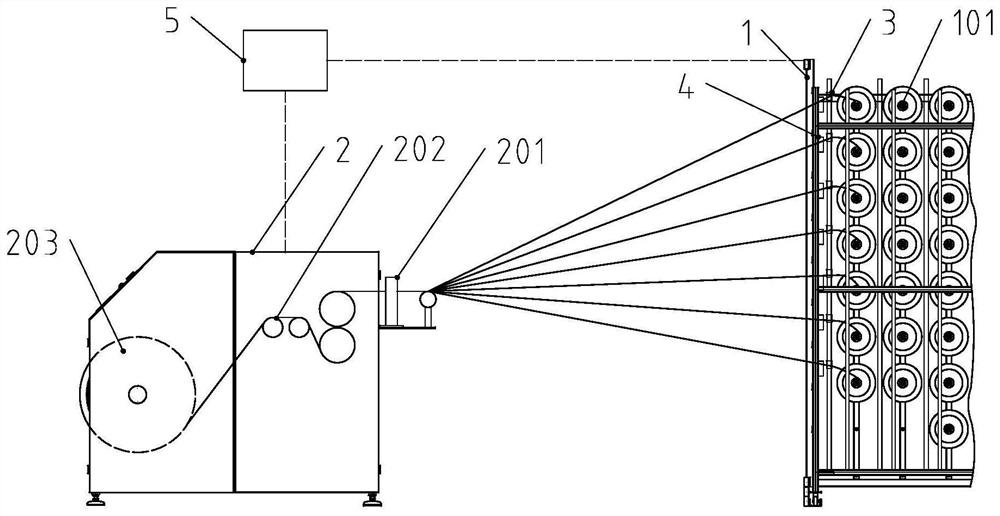

[0036] like figure 1 The shown high-strength glass fiber high-speed warping device includes a creel 1 for arranging warp bobbins, a warping machine head 2 for drawing out warp yarns from the creel 1 to form warp sheets, and a bobbin head 2 arranged on the creel 1. The tension buffer device 3 on the bobbin, the self-stop device 4 and the control device 5 for yarn breakage arranged on the creel 1.

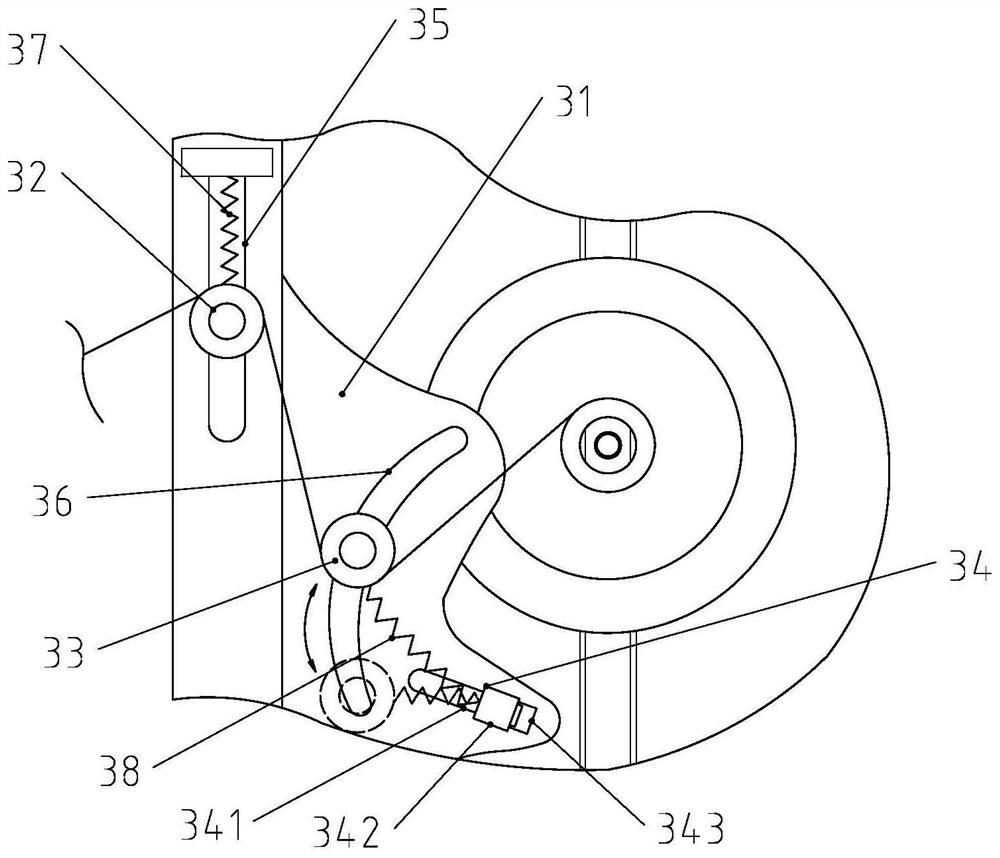

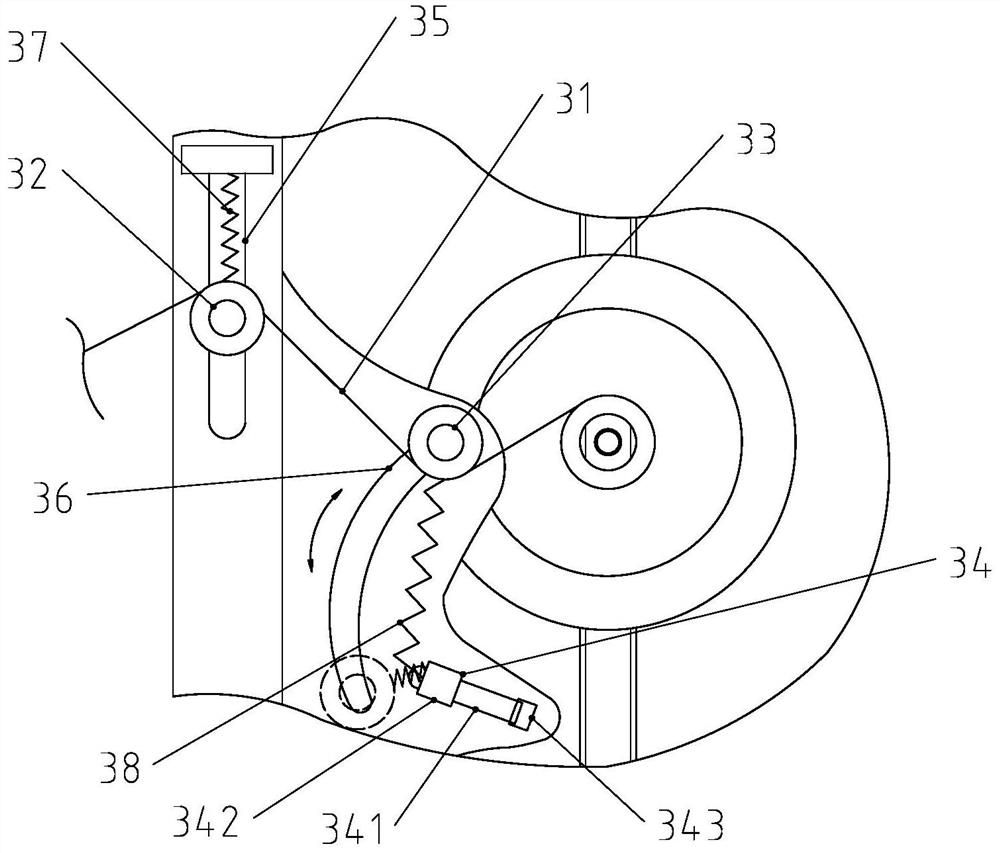

[0037] like figure 2 As shown, the tension buffer device 3 includes a bottom plate 31 , a first adjustment plate 32 , a second adjustment plate 33 and an amplitude adjustment mechanism 34 for adjusting the movement amplitude of the second adjustment plate 33 . The bottom plate 31 is provided with a first guide groove 35 and a second guide groove 36 for respectively restricting the movement trajectories of the first adjusting disk 32 and the second adjusting disk 33 . The first guide groove 35 and the second guide groove 36 are arranged at intervals, and the amplitude adjustment me...

Embodiment 2

[0042] like figure 1 The shown high-strength glass fiber high-speed warping device includes a creel 1 for arranging warp bobbins, a warping machine head 2 for drawing out warp yarns from the creel 1 to form warp sheets, and a bobbin head 2 arranged on the creel 1. The tension buffer device 3 on the bobbin, the self-stop device 4 and the control device 5 for yarn breakage arranged on the creel 1.

[0043] The creel 1 is provided with a bobbin brake 101 for stopping the rotation of the warp bobbin, and the bobbin brake 101 is electrically connected with the control device 5 . The bobbin brake 101 is used to provide a reverse braking force to the warp bobbin still in unwinding rotation to stop the rotation when the yarn is broken and stopped. The structure of the bobbin brake 101 is in the prior art and will not be repeated here.

[0044] The warping machine head 2 includes a telescopic reed 201, a yarn guide roller 202 and a warp beam 203. The telescopic reed 201, the yarn guid...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com