River levee slope protection sliding formwork device

A sliding form and embankment technology, applied in the field of embankment slope protection sliding form device, can solve the problems of long leveling time, slow leveling speed, time-consuming and laborious, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

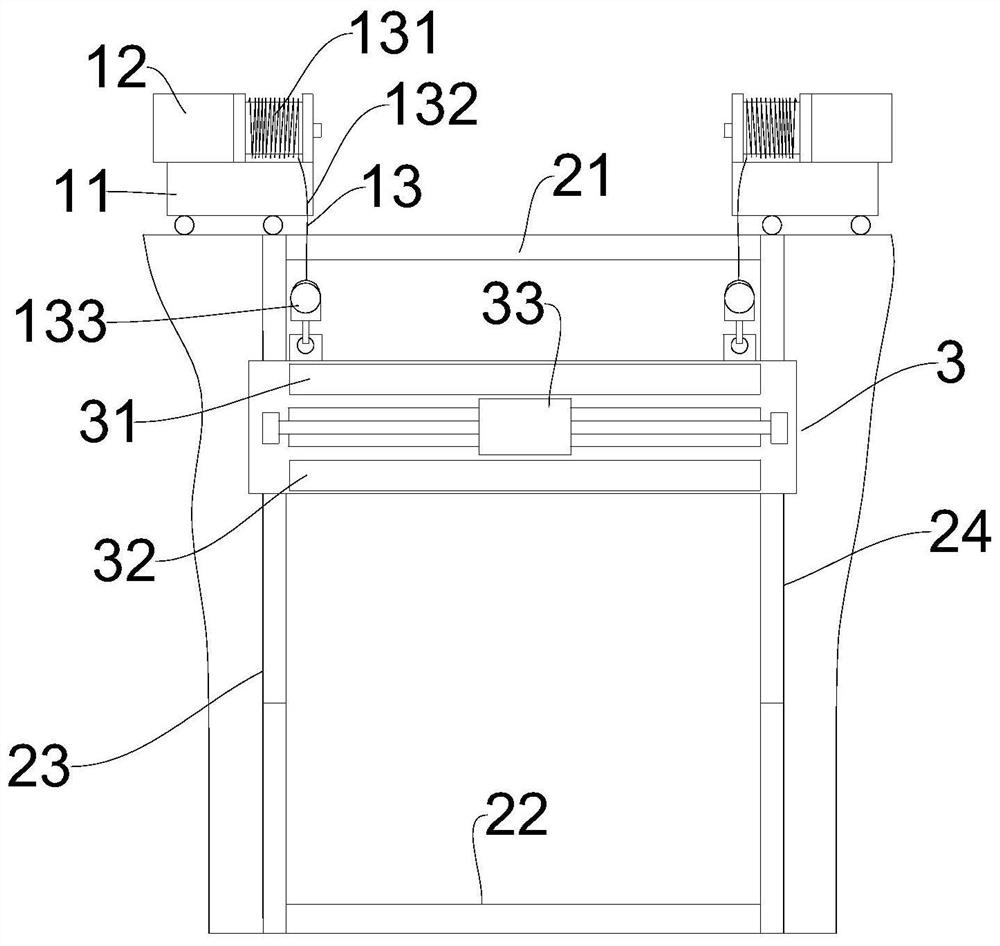

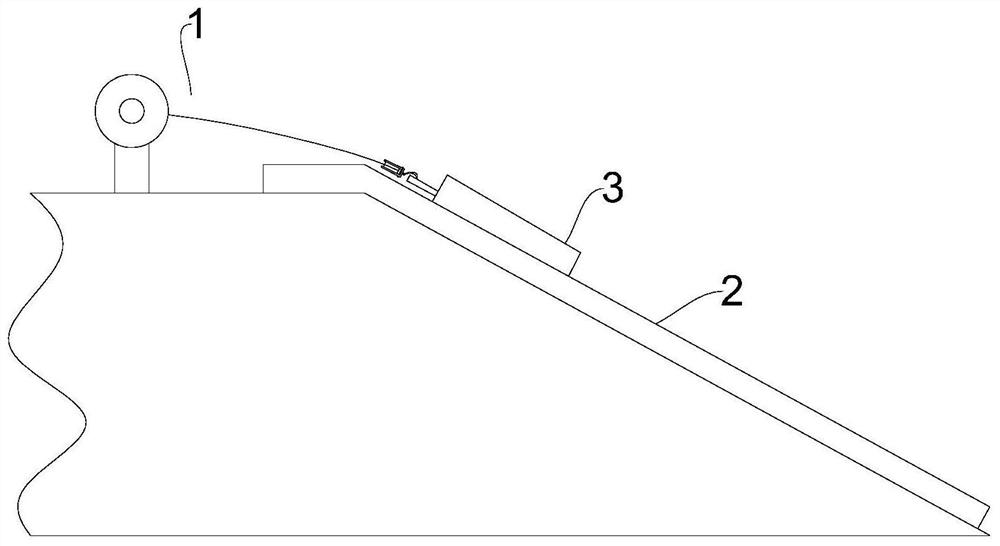

[0036] like Figure 1-7 As shown, the present embodiment provides a river embankment slope protection sliding form device, including a power assembly 1, a frame assembly 2 and a leveling assembly 3 for leveling the upper end of the mold material in the frame assembly 2. The output end of the component 1 is connected to the above-mentioned leveling component 3 , the above-mentioned leveling component 3 is arranged on the upper side wall of the above-mentioned frame component 2 , and the above-mentioned leveling component 3 is slidably connected to the above-mentioned frame component 2 .

[0037]In this embodiment, the frame assembly 2 is placed on the slope of the embankment, and together with the embankment surface forms the area where the mold material is placed, the construction workers may put the mold material (such as cement) into the frame body assembly 2, and finally put The frame component 2 is filled, and then the leveling component 3 is placed on the frame component ...

Embodiment 2

[0039] like Figure 1-7 As shown, in this embodiment, on the basis of Embodiment 1, the above-mentioned frame assembly 2 includes a front side panel 21, a rear side panel 22, a left side panel 23 and a right side panel 24, the above-mentioned front side panel 21, the above-mentioned left side panel 23. The rear side plate 22 and the right side plate 24 are detachably connected end to end, and the leveling assembly 3 is arranged on the upper ends of the left side plate 23 and the right side plate 24 .

[0040] In this embodiment, the front side plate 21, the left side plate 23, the rear side plate 22 and the right side plate 24 are detachably connected end to end to form the frame assembly 2, so that the frame assembly 2 can be disassembled during use, so that the frame assembly 2. It is more convenient to carry and build. When carrying, you only need to disassemble the frame assembly 2 into a front side panel 21, a left side panel 23, a rear side panel 22 and a right side pane...

Embodiment 3

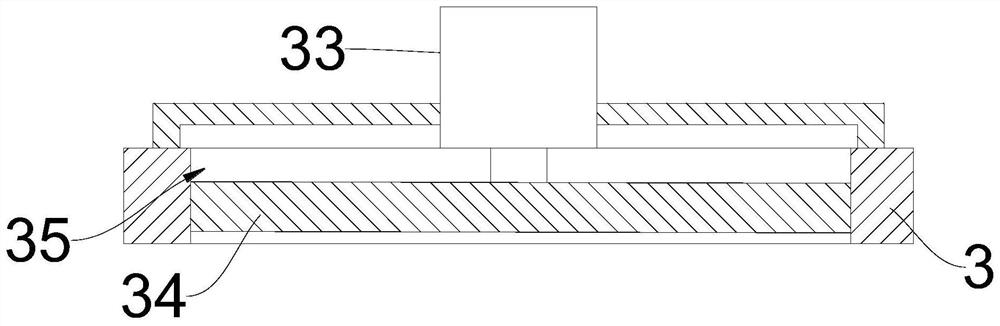

[0052] like Figure 1-7 As shown, in this embodiment, on the basis of some of the above-mentioned embodiments, the above-mentioned leveling assembly 3 includes a leveling plate, the above-mentioned leveling plate is arranged on the upper side wall of the above-mentioned frame body assembly 2, and the upper side wall of the above-mentioned leveling plate is provided with supplementary parts along the front and rear direction. The first material storage hole 31 of the mold material.

[0053] In this embodiment, the first material storage hole 31 is used to store some molding materials. During the leveling process of the leveling plate, if there is a pit on the upper end surface of the molding board, it is not necessary to manually add molding materials. The mold material in the material storage hole 31 will automatically flow into the pit, thereby realizing the effect of automatically replenishing the mold material, and continuing the leveling operation, which has a high degree ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com