Aluminum foil, cable with same and cable encasement method

A cable and aluminum foil technology, which is applied in the direction of double-stranded/quad-stranded cables, insulated cables, communication cables, etc., can solve the problems of reducing cables, occupying a lot of space for cables, and bulky winding reels. , to prevent electromagnetic interference, good bending, good sealing effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

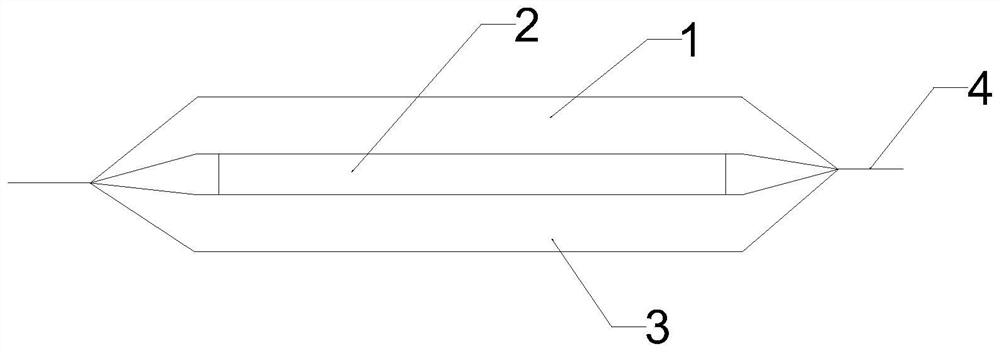

[0040] figure 1 A schematic diagram of the structure of an aluminum foil in the present application is shown. Such as figure 1 As shown, the aluminum foil includes a first insulating layer 1 , a metal layer 2 and a second insulating layer 3 , wherein the first insulating layer 1 and the second insulating layer 3 cover both sides of the metal layer 2 respectively. The width of the first insulating layer 1 and the second insulating layer 3 is greater than that of the metal layer 2 , so that a margin 4 without the metal layer 2 is formed on both sides between the first insulating layer 1 and the second insulating layer 3 . At the margin 4, the first insulation 1 and the second insulation 3 are bonded together by melting, so that an accommodation cavity is formed between the margins 4 on both sides, and the metal layer 2 is sealed in the accommodation cavity. .

[0041] In the above technical solution, the present application arranges the first insulating layer 1 and the second...

Embodiment 2

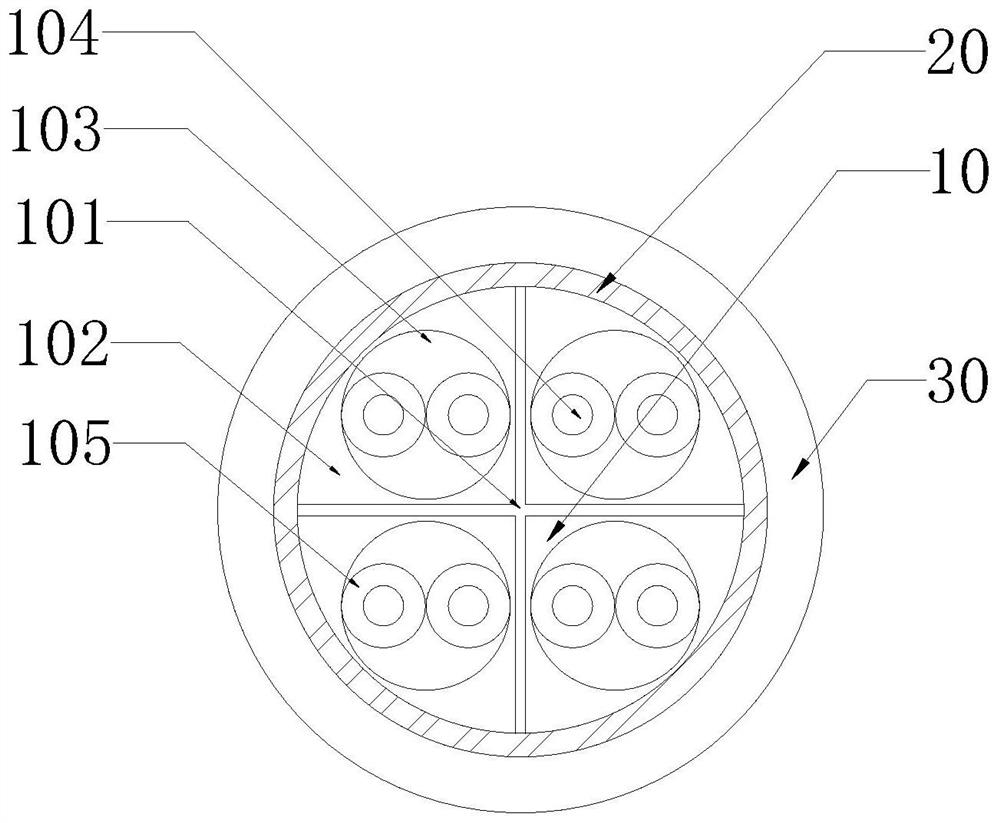

[0045] figure 2 The specific structure of a cable in the present application having an aluminum foil as described in Example 1 is shown. Such as figure 2 As shown, the cable includes a cable core 10, a shielding layer 20 and a sheath layer 30 from the inside to the outside, wherein the shielding layer 20 is wound or covered by the above-mentioned aluminum foil. In order to ensure its shielding effect, the shielding tape is wound or The overlapping parts of the cladding overlap, specifically, the overlapping ratio is greater than or equal to 25% in this embodiment. Since the inner and outer sides of the shielding layer 20 are provided with insulating materials (the first insulating layer 1 and the second insulating layer 3), the metal layer 2 is isolated from the cable core 10 and the sheath layer 30, so when in use, the metal The charge on layer 2 will not cause electrostatic interference inside and outside the cable. Compared with the existing FTP, it does not need additi...

Embodiment 3

[0051] The present application also discloses a method for packing cables, which is applied to the cables described in Embodiment 2, including the following steps:

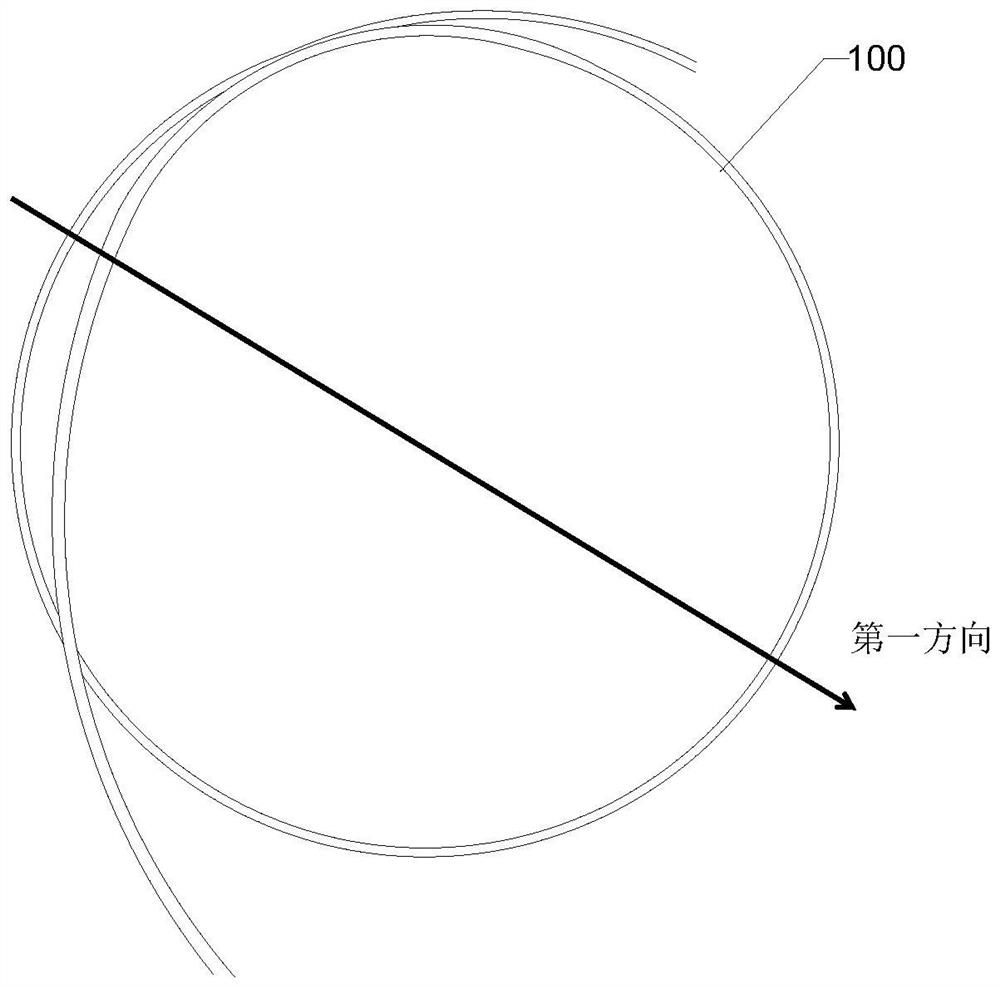

[0052] Winding for the first time: winding the cable once in the first direction to form a first coil 100; the diameter of the first coil 100 is the minimum bending diameter of the cable or the shortest inner side length of the carton;

[0053] Second winding: winding the cable once in a second direction to form a second winding coil 200 , the second direction being opposite to the first direction. The diameter of the second winding coil 200 is consistent with that of the first winding coil 100 . After the second winding is completed, the remaining cables are located between the first winding coil 100 and the second winding coil 200 .

[0054] Repeat the above actions until the cable winding is completed;

[0055] Pack the finished cable into the carton.

[0056] With this method of winding, the bending state o...

PUM

| Property | Measurement | Unit |

|---|---|---|

| melting point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com